Abstract

In the field of laser simulation, Visualization of intensity data is a very important work. The laser intensity data is characterized by scattered volumetric data and does not have relation information between each data. We used an iso-surface, a representative indirect volume rendering method, as a method to analyze the geometric characteristics of the intensity data. However, iso-surface visualization requires the proper choice of an iso-value. If you determine the iso-value in a fully interactive manner without any guidance, then the value will not be what you want most. Hence, most visualization tools involve preprocessing that analyzes the values and calculates the appropriate iso-value, but this method is not suitable for laser intensity data, which is the scattered volume data. To solve this problem, we divide the whole grid, and calculate the weights for the specific areas to derive the appropriate iso-value that the user wants.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Laser technology is very important in generating plasma waves. Plasma generated by passing a laser through a gas or a screen is utilized in various applications such as energy, new materials, semiconductor device manufacturing, and environmental fields required in the 21st century. The generation of high-efficiency plasmas is closely related to the development of high-intensity lasers. Therefore, in the study of high intensity plasma generation, visualization of intensity data is a very meaningful task [1,2,3,4].

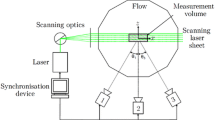

In general, volume visualization is performed using two approaches: direct volume rendering and surface rendering. Direct volume rendering algorithms render every voxel in the volume raster directly, without conversion to geometric primitives or first converting to a different domain and then rendering from that domain. On the other hand, surface rendering algorithms first fit geometric primitives to values in the data, and then render these primitives. Therefore, we have visualized the intensity data through iso-surface methods, one of the surface rendering methods that is easy to analyze the geometric characteristics (Fig. 1).

2 Problem Description

The iso-surface is a method of generating surface by connecting values having certain value, called iso-value, in volume data. The iso-value may be chosen in a purely interactive manner without any guidance. And the selected value may be inappropriate. The previous way to assist in determining iso-value is to use the histogram and previews. As a first level of support, the histogram of the dataset is displayed and labeled to enable the user to select a certain value. Previews, as a further supporting method, may be provided by rendering a down-sampled images and enable the user to select from them (Table 1).

The laser intensity data is characterized by scattered volumetric data. Figure 2 shows that the distribution of laser data is too broad (min: 9.0e−15, max: 2.5e + 03) to be represented through the histogram. In addition, there is a problem that big data requires a lot of time to process the preview each time. Therefore, programs such as MatLab take a built-in algorithm to compute and provide the appropriate iso-value. However, this is an advantageous method if the volume data has a clear surface, and is not a suitable method for scattered data with unclear surfaces such as laser intensity data. In addition, significant iso-values for users studying through visualization of laser intensity data may be different each time. Therefore, we propose an improved method to propose a moderate iso-value to the user [5,6,7].

3 Camera Metering System

There is a metering system in the camera that we can see easily around us. The metering system measures and calculates the amount of light that can be confirmed by the viewfinder and sets the appropriate exposure value. Considering that the laser intensity data is light intensity, we are adopting the concept of metering system in that it is the same as iso-value selection and camera exposure value selection. In Fig. 3, each camera is slightly different, but the basic metering system is spot, center-weighted, and matrix. We analyze these three methods and consider appropriate methods for analyzing laser intensity data [8, 9].

3.1 Spot Metering

Spot metering is a method of measuring the center of the area corresponding to about 3.5% of the area in the viewfinder (Fig. 4). This method is suitable for cases where the illumination difference between the background and the subject is large because only a specific portion is precisely measured irrespective of the overall brightness.

3.2 Center-Weighted Metering

Center-weighted metering focuses on the center of the viewfinder and then measures the overall average brightness. As shown in Fig. 5, the measured value of the central area corresponding to 20~30% of the viewfinder is weighted by 60~80%, and the measured value of the other area is weighted by 20~40%. Therefore, it is the most suitable measurement method when the subject is in the middle.

3.3 Matrix Metering

Matrix metering divides the entire screen into zones and then analyzes the exposure patterns of each zone through the built-in algorithm of each manufacturer. It then determines the exposure value of the average of all the zones. Different manufacturers have different exposure patterns, and Nikon has a database that contains more than 30,000 referenceable exposure information (Fig. 6).

4 Laser Intensity Metering System

The algorithm used in our proposed laser intensity metering system is based on algorithm embedded in MatLab. First, we convert the volume data to a histogram of N-bins, the range of values. Next, we average the remaining bins by removing mode value lower than the median, which are most likely to be a garbage. We used this filtering algorithm to determine the iso-values of the following measurement methods; entire volume metering, spot metering, center-weighted metering [10, 11].

4.1 Entire Volume Metering

Figure 7 shows the selected region in the entire volume data and the histogram of its region. As can be seen from Fig. 7, the bin count to the minimum value occupies the largest portion. Figure 8 shows the average values before and after removing the mode value. By eliminating the bin that is close to zero and occupies the most amount, we can see that the result is a more meaningful average.

4.2 Spot Metering

Figure 9 shows histograms in three randomly selected spots, which are 3.5% of the total volume. As you can see from the obvious difference between Spot 2 and the other two spots, the distribution of the values depends on the selected area. Furthermore, the distribution of the values of spots 1 and 3 is similar at first glance, but the magnitude of the maximum intensity value present in the area is different. Thus, the filtered iso-value is also different for each zone (Fig. 10).

4.3 Center-Weighted Metering

Figure 11 depicts about 25% of the entire volume and the histogram of selected area. The unweighted central area is equivalent to widening the area of spot 2 in Fig. 9. The central area has a relatively stable form of the distribution value as compared to the remaining area, but has relatively low intensity values.

In the center-weighted metering method, which is a mixed method of entire metering and spot metering, we use weighting method to reduce the difference in results depending on the selected position. The weighted average equation we used is:

In this equation \( w_{i} \) is the weight given in each area, and \( i_{i} \) is the iso-value of each area. We used this equation to assign a weight of 75% to the central area and 25% to the other areas. The result is shown in Fig. 12.

5 Visualization

In an experiment to visualize the iso-surface of the laser intensity data, we used VisIt. VisIt was developed by LLNL (Lawrence Livermore National Laboratory) and is an open source visualization tool for effectively representing science and engineering data by BSD licensing. In addition, VisIt is capable of visualizing data from over 120 different scientific data formats including HDF5 [12].

Table 2 shows the iso-values used in the experiment. The iso-values required to perform iso-surface were obtained through the methods described above; entire volume metering, spot metering and center-weighted metering; and those obtained through the built-in algorithm in MatLab.

Figure 13 is the result of surface rendering the laser intensity data through the iso-surface. Figure 13(e) and (f) show larger surfaces because they have lower iso-values than Fig. 13(a). In addition, the results of Fig. 13(b), (c), and (d) show that the surfaces of the laser intensity data are broken away in the form of islands.

The result of surface rendering by iso-values of Table 2

6 Conclusions

In this paper, we used iso-surface as a representative surface visualization method for geometric analysis to visualize laser intensity data. However, due to the properties of the scattered volumetric data of the laser intensity data, it is difficult to select appropriate iso-values for the iso-surface. Therefore, we adopted the camera metering system; A method of providing an average value by removing a value close to garbage in the entire region or selected spot, and a method of providing center-weighted average value. Through these methods, it is possible to suggest a more meaningful iso-value to the user. For further research, we are trying to provide a more appropriate iso-value by matrix pattern metering that reflects the user’s interest through machine learning.

.

References

Rübel, O., Geddes, C.G.R., Chen, M., Cormier-Michel, E., Bethel, E.W.: Feature-based analysis of plasma-based particle acceleration data. IEEE Trans. Vis. Comput. Graph. 20(2), 196–210 (2014)

Shin, H.S., Yu, T.J., Lee, K.: Visualization of scattered plasma-based particle acceleration data. J. Korea Multimedia Soc. 18(1), 65–70 (2015)

Lücke, P.: Volume Rendering Techniques for Medical Imaging. Technische Universität München (2005)

Preim, B., Botha, C.: Visual Computing for Medicine: Theory, Algorithms, and Applications, 2nd edn. Morgan Kaufmann, Burlington (2013)

Abbas, M.Z., Prasad, P.: Query-Based Visualization of Iso-Surfaces for Tetrahedral Meshes (2008)

Sanderson, A.R. Whitlock, B., Rübel, O., Childs, H., Weber, G., Wu, K.: A system for query based analysis and visualization. In: International Symposium Visual Analytics Science and Technology (2012)

Battiato, S., Messina, G., Castorina, A.: Exposure correction for imaging devices: an overview. In: Single-Sensor Imaging Methods Applications for Digital Cameras, pp. 323–349 (2008)

Nourani-Vatani, N., Roberts, J.M.: Automatic camera exposure control. In: Proceedings Australasian Conference on Robotics and Automation, pp. 1–6 (2007)

Metering Nikon. http://imaging.nikon.com/lineup/dslr/basics/18/01.htm

Visit LLNL. https://wci.llnl.gov/simulation/computer-codes/visit

Peterson, D.: Which is best? spot, center weight, or matrix metering? Digital Photo Secrets. http://www.digital-photo-secrets.com/tip/2879/which-is-best-spot-center-weight-or-matrix-metering

Shin, H.S., Song, J.H., Yu, T.J., Lee, K.: Creative interaction for plasma physics. In: Marcus, A. (ed.) DUXU 2016. LNCS, vol. 9748, pp. 214–222. Springer, Cham (2016). doi:10.1007/978-3-319-40406-6_20

Acknowledgments

This work was supported by the Industrial Strategic technology development program, 10048964, Development of 125 J∙Hz laser system for laser peering funded by Ministry of Trade, Industry & Energy (MI, Republic of Korea).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Song, J.H., Shin, H.S., Yu, T.J., Lee, K. (2017). Laser Intensity Data Visualization for Laser Physics. In: Marcus, A., Wang, W. (eds) Design, User Experience, and Usability: Designing Pleasurable Experiences. DUXU 2017. Lecture Notes in Computer Science(), vol 10289. Springer, Cham. https://doi.org/10.1007/978-3-319-58637-3_46

Download citation

DOI: https://doi.org/10.1007/978-3-319-58637-3_46

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58636-6

Online ISBN: 978-3-319-58637-3

eBook Packages: Computer ScienceComputer Science (R0)