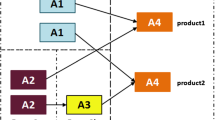

A scheduling problem arising in the iron and steel industry is discussed. It concerns the medium planning and the short-term scheduling of three tools: continuous-casting, strip mill and finishing, these three belonging to the hot unit of an iron and steel company. The strip mill is more constrained than the other two, it is therefore called the pivot, the continuous-casting tool is called the upstream tool and the finishing tool is called the downstream tool. A hierarchical approach consisting of two levels is designed. At each level of this hierarchy, the pivot is scheduled first followed by the other tools under the constraints of the pivot schedule. Methods are proposed to solve scheduling problems arising from this approach. Each of the methods is an approximation scheme because of the NP-hardness of the scheduling problems. Some of the approximation schemes are local search methods (simulated annealing improved by some specific techniques), others are specific constructive methods built to solve given problems. An interesting criterion is the following: the schedule of the pivot being given, the schedule of the upstream tool must begin as late as possible and the schedule of the downstream must end as soon as possible in order to minimize the inventory cost between the tools while minimizing the other costs of manufacturing such as the number of profile changes, the number of block changes, etc. The pivot medium-term solving is the most developed part of this paper and it is tested on some generated examples; the generator description and the numerical results are presented.

Similar content being viewed by others

References

Axsater, S. (1981) Aggregation of product data for hierarchical production planning. Operations Research, 29(4), July.

Guay, B. M. (1990) A backward, forward and midpoint scheduling system for multiple bottleneck operations. Wire Journal International, 23(4), April, 60, 63–64, 67, 69, 71.

Jacobs, T. L., Wright, J. R. and Cobbs, A. E. (1988) Optimal inter-process steel production scheduling. Computers & Operations Research, 15(6), 497–507.

Kirkpatrick, S., Gelatt, C. D. and Vecchi, M. P. (1982) Optimization by simulated annealing, IBM Research Report RC 9355.

Kirkpatrick, S., Gelatt, C. D. and Vecchi, M. P. (1983) Optimization by simulated annealing. Science, 220, May, 671–680.

Lu, Y. Z., Bao, L. W., Yang, Y. Y. and Li, B. Y. (1990) An integrated computer control system for a steel plate mill, in Automation in Mining, Mineral and Metal Processing, Selected Papers from the 6th IFAC Symposium, pp. 293–297.

Manheim, M. L., Srivastava, S., Vlahos, N., Hsu J. and Jones, P. (1990) A symbiotic decision support system for production planning and scheduling: issues and approaches, in Proceedings of the Twenty-Third Annual Hawaii International Conference on System Sciences, 3, pp. 383–390.

Nambiar, P. V. N. and Acharya, D. (1988) Decision support system for production planning: a steel plant experience, in Operational Research '87: Proceedings of the 11th International Conference, pp 145–160.

Nakagawa, M., Tanimoto, Y., Kiba, M. and Koriki, M. (1980) Production control system of hot strip mill. Sumitomo Search, 24, 133–143.

Portmann, M. C. and Camps, J. J. (1993) Steel coils scheduling in a flow shop with parallel tools and tight constraints, in Advances in Factories of the Future, CIM and Robotics, Cotsaftis, M. and Vernadat, F. (eds) Manufacturing Research and Technology, 16, 489–495.

Rohr, D. (1992) Gestion de production hiérarchisée appliquée en sidérurgie, Thèse CNAM, Centre Régional de Nancy.

Shah, M. J., Damian, R. and Silverman, J. (1990) Knowledge based dynamic scheduling in a steel plant, in 6th Conference on Artificial Intelligence Application, 1, pp. 108–113.

Tabucanon, M. T. and Sasiwong, B. (1991) Production planning and scheduling for a iron and steel production system. Applied Mathematical Modelling, 15(3), 164–168.

Thorsen, M. N. and Vidal, R. V. V. (1991) Operational research in the Danish steel industry. European Journal of Operational Research, 51(3), 301–309.

Vasko, F. J. and Friedel, D. C. (1982) A dynamic programming model for determining continuous-caster configurations. IIE Transactions, (1), 38–43.

Wright, J. R. and Houck, M. H. (1985) An application of systems modelling in steel production scheduling, in Proceedings of the 4th International Conference on Engineering Software, pp. 127–140.

Yasuda, H., Tokuyama, H. and Tarui, K. (1984) Two-stage algorithm for production scheduling of hot strip mill, in Operational Research '84: Proceedings of the 10th International Conference, pp. 588–600.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Portmann, M.C., Rohr, D. Hierarchical production management applied to an iron and steel industry. J Intell Manuf 6, 79–85 (1995). https://doi.org/10.1007/BF00123679

Issue Date:

DOI: https://doi.org/10.1007/BF00123679