Abstract

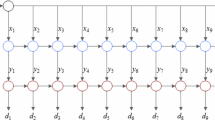

We will consider a concave minimization problem associated with a series production system in which raw material is processed inm consecutive facilities. The products at some facility are either sent to the next facility or stocked in the warehouse. The amount of demand for the final products during periodi, i = 1,⋯,n, are known in advance. Our problem is to minimize the sum of processing, holding and backlogging cost, all of which are assumed to be concave.

The origin of this model is the classical economic lot size problem of Wagner and Whitin and was extensively studied by Zangwill. This model is very important from the theoretical as well as practical point of view and this is one of the very rare instances in which polynomial time algorithm has been constructed for concave minimization problems.

The purpose of this paper is to extend the model further to the situation in which time lag is associated with processing at each facility. We will propose an efficient O(n 4 m) algorithm for this class of problems.

Similar content being viewed by others

References

P. Afentakis, B. Gavish and U. Karmarkar, “Computationally efficient optimal solution to the lot-sizing problem in multistage assembly systems,”Management Science 30 (1984) 222–239.

G.R. Bitran, T.L. Magnanti and H.H. Yanasse, “Approximation methods for the uncapacitated dynamic lot size problem,”Management Science 30 (1984) 1121–1140.

H.Konno, “Minimum concave series production system with deterministic demands - A backlogging case,”Journal of the Operations Research Society of Japan 16 (1973) 246–253.

S.F. Love, “A facilities in series inventory model with nested schedules,”Management Science 18 (1973) 327–338.

A.F. Veinott, Jr., “Minimum concave cost solution of Leontief substitution system model of multi-facility inventory system,”Operations Research 18 (1969) 262–299.

M.H. Wagner and T.M. Whitin, “Dynamic version of economic lot-sizing models,”Management Science 5 (1958) 89–96.

W.I. Zangwill, “Minimum concave cost flows in certain networks,”Management Science 14 (1968) 429–450.

W.I. Zangwill, “A backlogging model and a multi-echelon model of a dynamic economic lot size production system - A network approach,”Management Science 15 (1969) 506–527

W.I. Zangwill, “Set up cost reduction in series facility production,” Graduate School of Business, University of Chicago (January 1985).

W.I. Zangwill, “Identifying and eliminating inventory in a series facility production system,” Graduate School of Business, University of Chicago (March, 1985).

W.I. Zangwill, private communication (August, 1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Konno, H. Minimum concave cost production system: A further generalization of multi-echelon model. Mathematical Programming 41, 185–193 (1988). https://doi.org/10.1007/BF01580763

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01580763