Abstract.

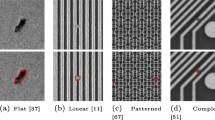

Visual defect inspection and classification are important parts of most manufacturing processes in the semiconductor and electronics industries. Defect classification provides relevant information to correct process problems, thereby enhancing the yield and quality of the product. This paper describes an automated defect classification (ADC) system that classifies defects on semiconductor chips at various manufacturing steps. The ADC system uses a golden template method for defect re-detection, and measures several features of the defect, such as size, shape, location and color. A rule-based system classifies the defects into pre-defined categories that are learnt from training samples. The system has been deployed in the IBM Burlington 16 M DRAM manufacturing line for more than a year. The system has examined over 100 000 defects, and has met the design criteria of over 80% classification rate and 80% classification accuracy. Issues involving system design tradeoff, implementation, performance, and deployment are closely examined.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chou, P., Rao, A., Sturzenbecker, M. et al. Automatic defect classification for semiconductor manufacturing . Machine Vision and Applications 9, 201–214 (1997). https://doi.org/10.1007/s001380050041

Issue Date:

DOI: https://doi.org/10.1007/s001380050041