Abstract.

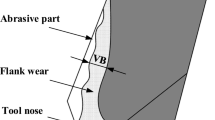

Tool wear affects the surface roughness dramatically. There is a very close correspondence between the geometrical features imposed on the tool by wear and micro-fracture and the geometry imparted by the tool on to the workpiece surface. Since a machined surface is the negative replica of the shape of the cutting tool, and reflects the volumetric changes in cutting-edge shape, it is more suitable to analyze the machined surface than look at a certain portion of the cutting tool. This paper discusses our work that analyzes images of workpiece surfaces that have been subjected to machining operations and investigates the correlation between tool wear and quantities characterizing machined surfaces. Our results clearly indicate that tool condition monitoring (the distinction between a sharp, semi-dull, or a dull tool) can be successfully accomplished by analyzing surface image data.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 9 June 1998 / Accepted: 6 October 1999

Rights and permissions

About this article

Cite this article

Kassim, A., Mannan, M. & Jing, M. Machine tool condition monitoring using workpiece surface texture analysis. Machine Vision and Applications 11, 257–263 (2000). https://doi.org/10.1007/s001380050109

Issue Date:

DOI: https://doi.org/10.1007/s001380050109