Abstract

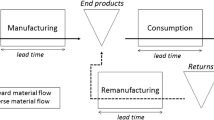

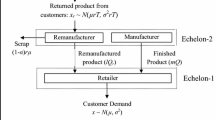

A simple dynamic model of a hybrid manufacturing/remanufacturing system is investigated. In particular we study an infinite horizon, continuous time, APIOBPCS (Automatic Pipeline Inventory and Order Based Production Control System) model. We use Åström’s method to quantify variance ratios in the closed loop supply chain. Specifically we highlight the effect of a combined “in-use” and remanufacturing lead-time and the return rate on the inventory variance and bullwhip produced by the ordering policy. Our results clearly show that a larger return rate leads to less bullwhip and less inventory variance in the plant producing new components. Thus returns can be used to absorb demand fluctuations to some extent. Longer remanufacturing and “in-use” lead-times have less impact at reducing inventory variance and bullwhip than shorter lead-times. We find that, within our specified system, that inventory variance and bullwhip is always less in supply chains with returns than supply chains without returns. We conclude by separating out the remanufacturing lead-time from the “in-use” lead-time and investigating its impact on our findings. We find that short remanufacturing lead-times do not qualitatively change our results.

Similar content being viewed by others

References

Åström KJ (1970) Introduction to stochastic control theory. Richard Bellman, University of Southern California

Barron Y, Frostig E, Levikson B (2004) Analysis of R out of N systems with several repairmen, exponential life times and phase type repair times: an algorithmic approach. Eur J Oper Res (forthcoming); available online at http://www.sciencedirect.com

Chen YF, Drezner Z, Ryan JK, Simchi-Levi D (2000) Quantifying the Bullwhip effect in a simple supply chain: the impact of forecasting, lead-times and information. Manage Sci 46:436–443

Dejonckheere J, Disney SM, Farasyn I, Janssen F, Lambrecht M, Towill DR, Van de Velde W (2002) Production and inventory control: the variability trade-off. Proceedings of the 9th EUROMA, June 2–4 2002, Copenhagen, Denmark, ISBN 1 85790 088x

Dejonckheere J, Disney SM, Lambrecht MR, Towill DR (2003) Measuring and avoiding the bullwhip effect: a control theoretic approach. Eur J Oper Res 47(3):567–590

Disney SM, Grubbström RW (2003) The economic consequences of a production and inventory control policy, 17th International Conference on Production Research, Virginia, USA, 3–7 August

Disney SM, Towill DR (2003) On the bullwhip and inventory variance produced by an ordering policy. OMEGA: Int J Manag Sci 31(3):157–167

Disney SM, Towill DR, Van de Velde W (2004) Variance amplification and the golden ratio in production and inventory control. Int J Prod Econ 90(3):295–309

Fleischmann M, Kuik R (2003) On optimal inventory control with independent stochastic item returns. Eur J Oper Res 151:25–37

Fleischmann M, Bolemhof-Ruwaard J, Dekker R, van der Laan E, van Nunen J, Van Wassenhove L (1997) Quantitative models for reverse logistics: a review. Eur J Oper Res 103:1–17

Guide VDR Jr (2000) Production planning and control for remanufacturing: industry practice and research needs. J Oper Manag 18:467–483

Inderfurth K, van der Laan E (2001) Lead-time effects and policy improvement for stochastic inventory control with remanufacturing. Int J Prod Econ 71:381–390

John S, Naim MM, Towill DR (1994) Dynamic analysis of a WIP compensated decision support system. Int J Manuf Syst Des 1(4):283–297

Kiesmüller GP (2003) A new approach for controlling a hybrid stochastic manufacturing/remanufacturing system with inventories and different lead-times. Eur J Oper Res 147:62–71

Kiesmüller GP, van der Laan EA (2001) An inventory model with dependent product demands and returns. Int J Prod Econ 72:73–87

Kleber R, Minner S, Kiesmüller G (2002) A continuous time inventory model for a product recovery system with multiple options. Int J Prod Econ 79:121–141

Kondo Y, Deguchi K, Hayashi Y (2003) Reversibility and disassembly time of part connection. Resour Conserv Recycl 38:175–184

Lee HL, Padmanabhan V, Whang S (1997) The bullwhip effect in supply chains. Sloan Management Review, Spring, pp 93–102

Lin GC, Kroll DE, Lin CJ (2005) Determining a common production cycle time for an economic lot scheduling problem with deteriorating items. Eur J Oper Res (forthcoming); available online at http://www.sciencedirect.com

Magee JF (1958) Production planning and inventory control. McGraw-Hill, New York, pp 80–83

Mahadevan B, Pyke DF, Fleischmann M (2003) Periodic review, push inventory policies for remanufacturing. Eur J Oper Res 151(3):536–551

Muckstadt J, Isaac MH (1981) An analysis of single item inventory systems with returns. Nav Res Logist Q 28:237–254

Newton GC, Gould LA, Kaiser JF (1957) Analytical design of linear feedback controls. Wiley, New York, pp 39–51

Nise NS (1994) Control systems engineering. California, Benjamin/Cummings

Seitz MA, Disney SM, Naim MM (2003) Managing product recovery operations: the case of automotive engine remanufacturing. EUROMA POMS Conference, Como Lake, Italy, 16–18 June, Vol 2, pp 1045–1053

Simon HA (1952) On the application of servomechanism theory to the study of production control. Econometrica 20:247–268

Sterman J (1989) Modelling managerial behaviour: misperceptions of feedback in a dynamic decision making experiment. Manage Sci 35(3):321–339

Tang O, Naim MM (2004) The impact of information transparency on the dynamic behaviour of a hybrid manufacturing/remanufacturing system. Int J Prod Res 42(19):4135–4152

Teunter RH, Vlachos D (2002) On the necessity of a disposal option for returned items that can be remanufactured. Int J Prod Econ 75:257–266

Thierry M, Salomon M, van Nunen J, van Wassenhove L (1995) Strategic issues in product recovery management. Calif Manage Rev 37(2):114–135

Towill DR (1970) Transfer function techniques for control engineers. Lliffe Books, London

Towill DR (1982a) Optimisation of an inventory and order based production control system. Proceedings of the 2nd International Symposium on Inventories, Budapest, Hungary

Towill DR (1982b) Dynamic analysis of an inventory and order based production control system. Int J Prod Res 20:369–383

Towill DR, Lambrecht MR, Disney SM, Dejonckheere J (2001) Explicit filters and supply chain design. Proceedings of the EUROMA conference, Salzburg, Austria, pp 401–411

van der Laan E (2003) An NPV and AC analysis of a stochastic inventory system with joint manufacturing and remanufacturing. Int J Prod Econ 81–82:317–331

van der Laan E, Salomon M, Dekker R (1999a) An investigation of lead-time effects in manufacturing/remanufacturing systems under simple PUSH and PULL control strategies. Eur J Oper Res 115:195–214

van der Laan E, Salomon M, Dekker R, van Wassenhove L (1999b) Inventory control in hybrid systems with remanufacturing. Manage Sci 45(5):733–747

Wang JH (2002) Adaptation of the beer game to reverse logistics. MSc Thesis, Cardiff Business School, Wales, UK

Wang CH (2004) The impact of a free-repair warranty policy on EMQ model for imperfect production systems. Comput Oper Res 31:2021–2035

Warburton RDH, Disney SM (2005) Variance amplification: the equivalence of discrete and continuous time analyses, 18th International Conference on Production Research, Salerno, Italy, 1–4 August

Wikner J, Towill DR, Naim MM (1991) Smoothing supply chain dynamics. Int J Prod Econ 22:231–248

Zhou L, Disney SM, Lalwani CS, Wu HL (2004) Reverse logistics: a study of bullwhip in continuous time. Proceedings of the 5th World Congress on Intelligent Control and Automation, Hangzhou, China, June 14–18, 2004, Vol 6(4), pp 3539–3542

Zhou L, Naim MM, Tang O, Towill DR (2005) Dynamic performance of a hybrid inventory system with a Kanban policy in remanufacturing process. OMEGA: Int J Manag Sci (forthcoming); available online on 5 March 2005

Author information

Authors and Affiliations

Corresponding author

Additional information

The authors would like to thank the anonymous referees who have provided invaluable critique.

Appendix A

Appendix A

Theorem

If the customer demand is drawn from an independently and identically distributed (i.i.d.) random distribution, then the following equation holds.

where g(t) is the time domain response and G(s) is its Laplace transform in the complex frequency domain. L −1 G(s)=g(t). y is the system’s output, that is, the order rate or the inventory levels. x is the input, the customer demand.

Proof

From the definition of Bullwhip, we have

.

The definition of σ 2 is well known to be

where E[y(t)] and E[x(t)] are the mean values of a process’s output and input respectively, denoted as μ(y) and μ(x). So

.

Suppose that the system is linear and the demand is at stationary process thus μ(y)=μ(x). (A1) can therefore be expressed by

.

We know that \(y{\left( t \right)} = {\int_{ - \infty }^{ + \infty } {g{\left( t \right)} \otimes } }\,x{\left( t \right)}dt\)where ⊗ denotes the convolution operator, then Eq. (A5) becomes

Furthermore, we notice that \({\int_{ - \infty }^0 {g{\left( t \right)}} }dt = 0\). This result shows that

Rights and permissions

About this article

Cite this article

Zhou, L., Disney, S.M. Bullwhip and inventory variance in a closed loop supply chain. OR Spectrum 28, 127–149 (2006). https://doi.org/10.1007/s00291-005-0009-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-005-0009-0