Abstract

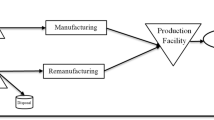

This paper investigates an uncapacitated multi-product production planning problem with returned product remanufacturing and demand substitution, where no backlog and no disposal are allowed. Both the production of new products and the remanufacturing of returned products are considered to meet time-varying demands in a finite time horizon. Setup costs are taken into account when a new product is manufactured or a returned product is remanufactured. The problem is to determine when and how many returned products are remanufactured and new products are manufactured so as to minimize the total cost, including manufacturing, remanufacturing, holding and substitution costs. We first develop an optimization model to formulate the problem. We then propose a dynamic programming approach to derive the optimal solution in the case with large quantities of returned products. We further propose an approximate approach for the general problem to compute a near-optimal solution. The proposed approaches are evaluated by computational experiments and the effectiveness of the approximate approach is verified. Some managerial insights regarding the effects of remanufacturing/substitution are also obtained from the computational studies.

Similar content being viewed by others

References

Aras N, Boyaci T, Verter V (2004) The effect of categorizing returned products in remanufacturing. IIE Trans 36:319–331

Balakrishnan A, Geunes J (2000) Requirements planning with substitutions: exploiting bill-of-materials flexibility in production planning. Manuf Serv Oper Manag 2:166–185

Bayindir ZP, Erkip N, Güllü R (2005) Assessing the benefits of remanufacturing option under one-way substitution. J Oper Res Soc 56:286–296

Beltrán JL, Krass D (2002) Dynamic lot sizing with returning items and disposals. IIE Trans 34:437–448

Golany B, Yang J, Yu G (2001) Economic lot-sizing with remanufacturing options. IIE Trans 33:995–1003

Guide VDR Jr, Van Wassenhove LN (2002) The reverse supply chain. Harvard Bus Rev 80(2):25–26

Hsu VN, Li C-L, Xiao W-Q (2005) Dynamic lot size problems with one-way product substitution. IIE Trans 37:201–215

Inderfurth K (2004) Optimal policies in hybrid manufacturing/remanufacturing systems with product substitution. Int J Prod Econ 90:325–343

Kleber R, Minner S, Kiesmuller G (2002) A continuous time inventory model for a product recovery system with multiple options. Int J Prod Econ 79:121–141

Leachman R (1987) Preliminary design and development of a corporate-level production system for the semiconductor industry. Working Paper ORC 86-11, Operations Research Center, University of California, Berkeley, CA

Magnanti T, Wong R (1984) Network design and transportation planning: models and algorithms. Transp Sci 18:1–55

Minner S, Kleber R (2001) Optimal control of production and remanufacturing in a simple recovery model with linear cost functions. OR-Spektrum 23:3–24

Padmanabhan V, Png IPL (1995) Returns policies: making money by making good. Sloan Manage Rev 37(1):65–72

Richter K, Sombrutzki M (2000) Remanufacturing planning for the reverse Wagner/Whitin models. Eur J Oper Res 121:304–315

Richter K, Weber J (2001) The reverse Wagner/Whitin model with variable manufacturing and remanufacturing cost. Int J Prod Econ 71:447–456

Souza GC, Ketzenberg ME, Guide VDR Jr (2002) Capacitated remanufacturing with service level constraints. Prod Oper Manag 11(2):231–248

Stephen AS, Agrawal N (2000) Management of multi-item retail inventory systems with demand substitution. Oper Res 48:50–64

Stock J, Speh T, Shear H (2002) Many happy (product) returns. Harvard Bus Rev 80(7):16–17

Yang J, Golany B, Yu G (2005) A concave-cost production planning problem with remanufacturing options. Nav Res Logist 52:443–458

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was partly supported by the National Science Foundation of China under Grant No. 70329001, 70321001, China Postdoctoral Science Foundation under Grant No. 2003034020, 70501014, SRF for ROCS, SEM (2004) and Hong Kong Research Grants Council under Earmarked Grant No. CUHK 4170/03E.

We wish to express our sincere appreciation to the Special Issue Editor and the two referees for their constructive comments and suggestions to help improve our paper.

Rights and permissions

About this article

Cite this article

Li, Y., Chen, J. & Cai, X. Uncapacitated production planning with multiple product types, returned product remanufacturing, and demand substitution. OR Spectrum 28, 101–125 (2006). https://doi.org/10.1007/s00291-005-0012-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-005-0012-5