Abstract

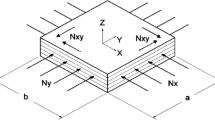

A procedure to design symmetrically laminated plates under buckling loads for minimum mass with manufacturing uncertainty in the ply angle, which is the design variable, is described. A minimum buckling load capacity is the design constraint implemented. The effects of bending–twisting coupling are neglected in implementing the procedure, and the golden section method is used as the search technique, but the methodology is flexible enough to allow any appropriate problem formulation and search algorithm to be substituted. Three different tolerance scenarios are used for the purposes of illustrating the methodology, and plates with varying aspect ratios and loading ratios are optimally designed and compared.

Similar content being viewed by others

References

Adali S, Richter A, Verijemko VE (1995) Minimum weight design of symmetric angle-ply laminates under multiple uncertain loads. Struct Optim 9:89–95

Tauchert TR, Adibhatla A (1984) Design of laminated plates for maximum stiffness. J Compos Mater 18:58–69

Quian B, Reiss R, Aung W (1990) The maximum stiffness design of rectangular symmetric angle-ply laminates. In: Proceedings of the 2nd international conference on computer aided design in composite material technology. Free University of Brussels/Wessex Institute of Technology, Computational Mechanics Publications, Southampton, pp 451–464

Kengtung C (1986) Sensitivity analysis and a mixed approach to the optimisation of symmetric layered composite plates. Eng Optim 9:233–248

Kam TY, Chang RR (1992) Optimum layup of thick laminated composite plates for maximum stiffness. Eng Optim 19:237–249

Adali S, Summers EB, Verijenko VE (1994) Minimum weight and deflection design of thick sandwich laminates via sumbolic computation. Compos Struct 29:145–160

Phillips JL, Gürdal Z (1990) Analysis and optimal design of geodesically stiffened composite panels. In: Proceedings of the 2nd international conference on computer aided design in composite material technology. Free University of Brussels/Wessex Institute of Technology, Computational Mechanics Publications, Southampton, pp 509–520

Triantafillou TC, Kim P, Meier U (1991) Optimisation of hybrid aluminium/c.f.r.p box beams. Int J Mech Sci 33(9):729–739

Min KT, de Charenteney FX (1986) Optimum weight design of sandwich cylinders with orthotropic facings and core under combined loads. Comput Struct 24(2):313–322

Ostwald M (1990) Optimum weight design of sandwich cylindrical shells under combined loads. Comput Struct 11:247

Walker M, Reiss T, Adali S (1997) Optimal design of symmetrically laminated plates for minimum deflection and weight. Compos Struct 39(3, 4):337–346

Lucoshevichyus RS (1976) Minimizing the mass of reinforced rectangular plates compressed in two directions in a manner conductive toward stability. Polym Mech 12:929–933

Shin DK, Gürdal Z, Griffin OH (1991) Minimum weight design of laminated plates for postbuckling performance. In: Proceedings of the 32nd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference, Baltimore, Maryland, 267–274

Walker M, Reiss T, Adali S (1997) Minimum weight design of composite hybrid shells via symbolic computation. J Franklin Inst 334B(1):47–56

Walker M, Reiss T, Adali S (1997) A procedure to select the best material combinations and optimally design hybrid composite plates for minimum weight and cost. Eng Opt 29:65–83

Walker M, Smith RE (2002) A computational methodology to select the best material combinations and optimally design composite sandwich panels for minimum cost. Comput Struct 80:1457–1460

Walker M, Smith RE (2006) A procedure to select the best material combination and optimally design composite sandwich cylindrical shells for minimum mass. Mater Des 27:160–165

Walker M, Smith RE (2003) A methodology to design laminated composite structures for maximum strength. Composites Part B 34:209–214

Walker M, Smith RE (2003) A simple self-design methodology for laminated composite structures to minimise mass. Adv Eng Softw 34:601–605

Walker M, Smith RE (2006) A technique for using genetic algorithms and finite element analysis to minimise the mass of laminated structures. Finite Elements Anal Des (in press)

Walker M, Smith RE (2003) A technique for the multiobjective optimisation of laminated composite structures using genetic algorithms and finite element analysis. Compos Struct 62:123–128

Messac A, Sundararaj GJ (2002) A robust design approach using physical programming, AIAA-2000-0562

Bates SJ, Sienz J, Pittman JFT, Langley DS (2002) Application of robust design optimisation to extrusion slit die design. In: Topping BHV and Bittnar Z (eds) Proceedings of the 3rd international conference on engineering computational technology, Civil-Comp Press, Stirling, Paper 62

Liou JH, Jang DY (1997) Forging parameter optimisation considering stress distributions in products through FEM analysis and robust design methodology. Int J Mach Tools Manuf 37(6):775–782

Lee KH, Park GJ (2002) Robust optimisation in discrete design space for constrained problems. AIAA J 40(4):774–780

Chiang YJ (1996) Robust design of the Iosipescu shear test specimen for composites. J Test Eval, JTEVA 24(1):1–11

Walker M, Hamilton R (2005) A methodology for optimally designing fibre-reinforced laminated structures with design variable tolerances for maximum buckling strength. Thin Wall Struct 43:161–174

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Walker, M., Hamilton, R. A technique for optimally designing fibre-reinforced laminated plates under in-plane loads for minimum weight with manufacturing uncertainties accounted for. Engineering with Computers 21, 282–288 (2006). https://doi.org/10.1007/s00366-006-0017-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-006-0017-y