Abstract

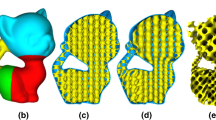

Recently, 3D printing has become a powerful tool for personal fabrication. However, the price of some materials is still high which limits its applications in home users. To optimize the volume of the model, while not largely affecting the strength of the objects, researchers propose algorithms to divide the model with different kinds of lightweight structures, such as frame structure, honeycomb cell structure, truss structure, medial axis tree. However, these algorithms are not suitable for the model whose internal space needs to be reused. In addition, the structural strength and static stability of the models, obtained with modern 3D model acquirement methods, are not guaranteed. In consequence, some models are too fragile to print and cannot be survived in daily usage, handling, and transportation or cannot stand in a stable. To handle the mentioned problems, an algorithm system is proposed based on cross sections in this work. The structural weak cross sections are enhanced, and structural strong cross sections are adaptively hollowed to meet a given structural strength, static stability, printability, etc., while the material usage is minimized. The proposed algorithm system has been tested on several typical 3D models. The experimental results demonstrate the effectiveness and practicability of our system.

Similar content being viewed by others

References

Bächer, M., Bickel, B., James, D.L., Pfister, H.: Fabricating articulated characters from skinned meshes. ACM Trans. Graph. (TOG) 31(4), 47 (2012)

Bächer, M., Whiting, E., Bickel, B., Sorkine-Hornung, O.: Spin-it: optimizing moment of inertia for spinnable objects. ACM Trans. Graph. (TOG) 33(4), 96 (2014)

Cacciola, F.: 2D straight skeleton and polygon offsetting. In: CGAL User and Reference Manual, 4.2 edn. CGAL Editorial Board (2013)

Ceylan, D., Li, W., Mitra, N.J., Agrawala, M., Pauly, M.: Designing and fabricating mechanical automata from mocap sequences. ACM Trans. Graph. (TOG) 32(6), 186 (2013)

Chen, Y., Wang, C.C.: Uniform offsetting of polygonal model based on layered depth-normal images. Comput.-Aided Des. 43(1), 31–46 (2011)

Cura: 3d printing software—cura. https://ultimaker.com/en/products/cura-software, year = 2016

Dumas, J., Hergel, J., Lefebvre, S.: Bridging the gap: automated steady scaffoldings for 3d printing. ACM Trans. Graph. (TOG) 33(4), 98 (2014)

Fu, H., Cohen-Or, D., Dror, G., Sheffer, A.: Upright orientation of man-made objects. In: ACM Transactions on Graphics (TOG), vol. 27, p. 42. ACM (2008)

Gottschalk, S., Lin, M.C., Manocha, D.: Obbtree: a hierarchical structure for rapid interference detection. In: Proceedings of the 23rd Annual Conference on Computer Graphics and Interactive Techniques, pp. 171–180. ACM (1996)

Hildebrand, K., Bickel, B., Alexa, M.: Orthogonal slicing for additive manufacturing. Comput. Graph. 37(6), 669–675 (2013)

Hoffmann, C.M.: Geometric and Solid Modeling (1989)

Kim, S.J., Lee, D.Y., Yang, M.Y.: Offset triangular mesh using the multiple normal vectors of a vertex. Comput.-Aided Des. Appl. 1(1–4), 285–291 (2004)

Liu, S., Wang, C.C.: Fast intersection-free offset surface generation from freeform models with triangular meshes. IEEE Trans. Autom. Sci. Eng. 8(2), 347–360 (2011)

Lu, L., Sharf, A., Zhao, H., Wei, Y., Fan, Q., Chen, X., Savoye, Y., Tu, C., Cohen-Or, D., Chen, B.: Build-to-last: strength to weight 3d printed objects. ACM Trans. Graph. (TOG) 33(4), 97 (2014)

Makerbot: Rapid prototyping and 3D printing. http://www.makerbot.com/ (2012)

Makerware: 3d printing software—makerware. http://www.makerbot.com/blog/2013/12/09/makerbot-makerware-2-4-1-release, year = 2016

Meyers, D., Skinner, S., Sloan, K.: Surfaces from contours. ACM Trans. Graph. (TOG) 11(3), 228–258 (1992)

Musialski, P., Auzinger, T., Birsak, M., Wimmer, M., Kobbelt, L.: Reduced-order shape optimization using offset surfaces. ACM Trans. Graph. 34(4), 102 (2015)

Musialski, P., Hafner, C., Rist, F., Birsak, M., Wimmer, M., Kobbelt, L.: Non-linear shape optimization using local subspace projections. ACM Trans. Graph. 35(4) (2016)

Nocedal, J., Wright, S.: Numerical optimization. Springer, New York (2006)

Pintus, R., Gobbetti, E., Cignoni, P., Scopigno, R.: Shape enhancement for rapid prototyping. Vis. Comput. 26(6–8), 831–840 (2010)

Porumbescu, S.D., Budge, B., Feng, L., Joy, K.I.: Shell maps. ACM Trans. Graph. 24(3), 626–633 (2005). doi:10.1145/1073204.1073239

Prévost, R., Whiting, E., Lefebvre, S., Sorkine-Hornung, O.: Make it stand: balancing shapes for 3d fabrication. ACM Trans. Graph. (TOG) 32(4), 81 (2013)

e Sá, A.M., Mello, V.M., Echavarria, K.R., Covill, D.: Adaptive voids. Vis. Comput. 31(6–8), 799–808 (2015)

Schmidt, R., Umetani, N.: Branching support structures for 3d printing. In: ACM SIGGRAPH 2014 Studio, p. 9. ACM (2014)

Sorkine, O., Alexa, M.: As-rigid-as-possible surface modeling. In: Proceedings of EUROGRAPHICS/ACM SIGGRAPH Symposium on Geometry Processing, pp. 109–116 (2007)

Stava, O., Vanek, J., Benes, B., Carr, N., Měch, R.: Stress relief: improving structural strength of 3D printable objects. ACM Transactions on Graphics (Proc. SIGGRAPH) 31(4), 48:1–11 (2012)

Sun, T., Zheng, C., Zhang, Y., Yin, C., Zheng, C., Zhou, K., Yue, Y., Smith, B., Batty, C., Xu, Z., et al.: Computational design of twisty joints and puzzles. ACM Trans. Graph. (TOG) 34(4), 101 (2015)

Umetani, N., Schmidt, R.: Cross-sectional structural analysis for 3d printing optimization. SIGGRAPH Asia 5, 1–4 (2013)

Vanek, J., Galicia, J., Benes, B.: Clever support: efficient support structure generation for digital fabrication. In: Computer Graphics Forum, vol. 33, pp. 117–125. Wiley Online Library (2014)

Vanek, J., Galicia, J., Benes, B., Měch, R., Carr, N., Stava, O., Miller, G.: Packmerger: a 3d print volume optimizer. Comput. Graph. Forum 33(6), 322–332 (2014)

Wang, C.C., Manocha, D.: Gpu-based offset surface computation using point samples. Comput.-Aided Des. 45(2), 321–330 (2013)

Wang, L., Whiting, E.: Buoyancy optimization for computational fabrication. In: Computer Graphics Forum, vol. 35, pp. 49–58. Wiley Online Library (2016)

Wang, W., Chao, H., Tong, J., Yang, Z., Tong, X., Li, H., Liu, X., Liu, L.: Saliency-preserving slicing optimization for effective 3d printing. In: Computer Graphics Forum, vol. 34, pp. 148–160. Wiley Online Library (2015)

Wang, W., Liu, X., Liu, L.: Upright orientation of 3d shapes via tensor rank minimization. J. Mech. Sci. Technol. 28(7), 2469–2477 (2014)

Wang, W., Wang, T.Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., Liu, X.: Cost-effective printing of 3d objects with skin-frame structures. ACM Trans. Graph. (TOG) 32(6), 177 (2013)

Wang, W.M., Zanni, C., Kobbelt, L.: Improved surface quality in 3d printing by optimizing the printing direction. In: Computer Graphics Forum, vol. 35, pp. 59–70. Wiley Online Library (2016)

Xie, Y., Xu, W., Yang, Y., Guo, X., Zhou, K.: Agile structural analysis for fabrication-aware shape editing. Comput. Aided Geom. Des. 35, 163–179 (2015)

Xu, W., Li, W., Liu, L.: Skeleton-sectional structural analysis for 3d printing. J. Comput. Sci. Technol. (In press) 31(3) (2016)

Yamanaka, D., Suzuki, H., Ohtake, Y.: Density aware shape modeling to control mass properties of 3d printed objects. In: SIGGRAPH Asia 2014 Technical Briefs, p. 7. ACM (2014)

Zhang, X., Le, X., Wu, Z., Whiting, E., Wang, C.C.L.: Data-driven bending elasticity design by shell thickness. Comput. Graph. Forum 35(5), 157–166 (2016)

Zhang, X., Xia, Y., Wang, J., Yang, Z., Tu, C., Wang, W.: Medial axis treełan internal supporting structure for 3d printing. Comput. Aided Geom. Des. 35, 149–162 (2015)

Zhao, H., Xu, W., Zhou, K., Yang, Y., Jin, X., Wu, H.: Stress-constrained thickness optimization for shell object fabrication. In: Computer Graphics Forum. Wiley Online Library (2016)

Zhou, Q., Panetta, J., Zorin, D.: Worst-case structural analysis. ACM Trans. Graph. (TOG) 32(4), 137 (2013)

Zhu, L., Xu, W., Snyder, J., Liu, Y., Wang, G., Guo, B.: Motion-guided mechanical toy modeling. ACM Trans. Graph. 31(6), 127 (2012)

Acknowledgements

We would like to thank the reviewers for their detailed comments and suggestions which greatly improved the manuscript. The research leading to these results has received funding from China Postdoctoral Science Foundation (2016M601308), the One Hundred Talent Project of the Chinese Academy of Sciences, Fundamental Research Fund (DUT16RC(3)061), National Natural Science Foundation of China (61370143, 61432003, 61661130156, 61672482, 11626253, 11472073 ), Hong Kong RGC GRF (14207414), and Royal Society-Newton Advanced Fellowship (NA150431).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Li, B., Qian, S. et al. Cross section-based hollowing and structural enhancement. Vis Comput 33, 949–960 (2017). https://doi.org/10.1007/s00371-017-1386-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00371-017-1386-5