Abstract

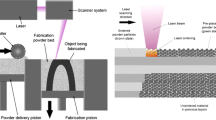

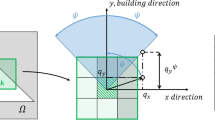

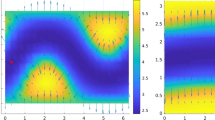

This paper presents an application framework that provides a complete process to design an optimized self-supporting structure, ready to be fabricated via additive manufacturing without the usage of additional support structures. Such supports in general have to be created during the fabricating process so that the primary object can be manufactured layer by layer without collapse; this process is very time-consuming and waste of material. The main approach resolves this issue by formulating the self-supporting requirements as an explicit quadratic continuous constraint in a topology optimization problem, or specifically, requiring the number of unsupported elements (in terms of the sum of squares of their densities) to be zero. Under the formulation, the required sensitivity of the self-supporting constraint with respect to the design density can be derived straightforward and is only linearly dependent on the density of the element itself. In addition, a novel discrete convolution operator is particularly designed to detect the unsupported elements. The approach works for cases of general overhang angles, and the produced optimized structures have close target compliance to those of the reference structures obtained without considering the self-supporting constraint, as demonstrated by various 2D and 3D benchmark examples.

Similar content being viewed by others

References

Bendsoe, M., Kikuchi, N.: Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 71(2), 197–224 (1988)

Bendsøe, M.P.: Optimal shape design as a material distribution problem. Struct. Optim. 1(4), 193–202 (1989)

Xie, Y.M., Steven, G.P.: A simple evolutionary procedure for structural optimization. Comput. Struct. 49(5), 885–896 (1993)

Huang, X., Xie, Y.M.: A further review of ESO type methods for topology optimization. Struct. Multidiscip. Optim. 41, 671–683 (2010)

Wang, M.Y., Wang, X., Guo, D.: A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 192, 227–246 (2003)

van Dijk, N.P., Maute, K., Langelaar, M., van Keulen, F.: Level-set methods for structural topology optimization: a review. Struct. Multidiscip. Optim. 48(3), 437–472 (2013)

Qian, X.: Topology optimization in B-spline space. Comput. Methods Appl. Mech. Eng. 265, 15–35 (2013)

Hughes, T.J.R., Cottrell, J.A., Bazilevs, Y.: Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 194(39), 4135–4195 (2005)

Sigmund, O., Maute, K.: Topology optimization approaches: a comparative review. Struct. Multidiscip. Optim. 48(6), 1031–1055 (2013)

Sigmund, O.: On Topology Optimization with Manufacturing Constraints. Springer, Netherlands (2006)

Serphos MR (2014) Incorporating AM-specific manufacturing constraints into topology optimization. Master thesis. Report no: EM 2014.011, Delft University of Technology. https://repository.tudelft.nl/islandora/object/uuid:64200c38-704d-426f-a423-d0dd6f543213?collection=education

Liu, J., Ma, Y.: A survey of manufacturing oriented topology optimization methods. Adv. Eng. Softw. 100, 161–175 (2016)

Langelaar, M.: An additive manufacturing filter for topology optimization of print-ready designs. Struct. Multidiscip. Optim. 55, 1–13 (2016)

Langelaar, M.: Topology optimization of 3D self-supporting structures for additive manufacturing. Addit. Manuf. 12, 60–70 (2016)

Daniel, T.: The development of design rules for selective laser melting. University of Wales, Cardiff (2009)

Majhi, J., Janardan, R., Schwerdt, J., Smid, M., Gupta, P.: Minimizing support structures and trapped area in two-dimensional layered manufacturing. Computat. Geom. 12(3–4), 241–267 (1999)

Wang, W., Wang, T.Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., Liu, X.: Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 32(6), 1–10 (2013)

Dumas, J., Hergel, J., Lefebvre, S.: Bridging the gap: automated steady scaffoldings for 3D printing. ACM Trans. Graph. 33(4), 1–10 (2014)

Brackett, D., Ashcroft, I., Hague, R.: Topology optimization for additive manufacturing. In: Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, 2011, pp. 348–362

Gaynor, A.T., Guest, J.K.: Topology optimization for additive manufacturing: considering maximum overhang constraint. In: AIAA AVIATION 2014—15th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, pp. 1–9 (2014)

Gaynor, A.T., Guest, J.K.: Topology optimization considering overhang constraints: eliminating sacrificial support material in additive manufacturing through design. Struct. Multidiscip. Optim. 54(5), 1157–1172 (2016)

Qian, X.: Undercut and overhang angle control in topology optimization: a density gradient based integral approach. Int. J. Numer. Methods Eng. 111(3), 247–272 (2017)

Garaigordobil, A., Ansola, R., Santamaría, J., de Bustos, I.F.: A new overhang constraint for topology optimization of self-supporting structures in additive manufacturing. Struct. Multidiscip. Optim. 58(5), 2003–2017 (2018)

Allaire, G., Dapogny, C., Estevez, R., Faure, A., Michailidis, G.: Structural optimization under overhang constraints imposed by additive manufacturing technologies. J. Comput. Phys. 351, 295–328 (2017)

Mirzendehdel, A.M., Suresh, K.: Support structure constrained topology optimization for additive manufacturing. Comput. Aided Des. 81, 1–13 (2016)

Lee, M., Fang, Q., Cho, Y., Ryu, J., Liu, L., Kim, D.-S.: Support-free hollowing for 3D printing via voronoi diagram of ellipses. Comput. Aided Des. 101, 23–36 (2018)

Wang, W., Liu, Y.-J., Wu, J., Tian, S., Wang, C.C., Liu, L., Liu, X.: Support-free hollowing. IEEE Trans. Visual Comput. Graph. 24(10), 2787–2798 (2017)

Xie, Y., Chen, X.: Support-free interior carving for 3D printing. Vis. Inform. 1(1), 9–15 (2017)

Wu, J., Wang, C.L., Zhang, X., Westermann, R.: Self-supporting rhombic infill structures for additive manufacturing. Comput. Aided Des. 80, 32–42 (2016)

Wu, J.: Continuous optimization of adaptive quadtree structures. Comput. Aided Des. 102, 72–82 (2017)

Chengkai, D., Chenming, W.C.C.L.W., Sylvain, L., Guoxin, F., Yong-Jin, L.: Support-free volume printing by multi-axis motion. ACM Trans. Graph. 37(4), 1–14 (2018)

Langelaar, M.: Combined optimization of part topology, support structure layout and build orientation for additive manufacturing. Struct. Multidiscip. Optim. 57(5), 1–20 (2018)

Guo, X., Zhang, W., Zhong, W.: Explicit feature control in structural topology optimization via level set method. Comput. Methods Appl. Mech. Eng. 272, 354–378 (2014)

Sigmund, O.: A 99 line topology optimization code written in matlab. Struct. Multidiscip. Optim. 21(2), 120–127 (2001)

Guest, J., Prevost, J., Belytschko, T.: Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Int. J. Numer. Methods Eng. 61(2), 238–254 (2004)

Dłaz, A., Sigmund, O.: Checkerboard patterns in layout optimization. Struct. Multidiscip. Optim. 10(1), 40–45 (1995)

Acknowledgements

The valuable comments and suggestions from the anonymous reviewers are greatly appreciated. The work described in this paper is partially supported by the NSF of China (No. 61872320) and the National Key Research and Development Program (No. 2016YFC1101302) from the MIST of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, D., Li, M. & Liu, Y. A novel application framework for self-supporting topology optimization. Vis Comput 37, 1169–1184 (2021). https://doi.org/10.1007/s00371-020-01860-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00371-020-01860-2