Abstract

Hydraulic cylinders perform straight-line reciprocating movements, and they have been used widely in various forms in many different industries. In this paper, we select a sample of the various types of standard hydraulic cylinders. Each cylinder’s near-optimal processing time and the processing order of the cylinder’s parts are investigated using two different techniques. First, we study typical procedures, known as ‘Dispatching Rules’, which would be used in a job shop to resolve scheduling problems. Second, we investigate another kind of technique, called ‘Genetic Algorithms’. The goal of this paper, we show that efficient scheduling solutions are calculated by using dispatching rules and genetic algorithms for manufacturing standard hydraulic cylinders, and we propose that a way to use dispatching rules in association with genetic algorithms should be considered for resolving job shop scheduling problems.

Similar content being viewed by others

Abbreviations

- F :

-

Force

- S :

-

Area of a piston

- P :

-

Fluid pressure

- V :

-

Volume

- Q :

-

Flow

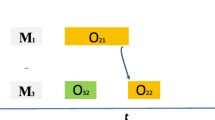

- M i :

-

Machine, i = 1, 2, . . . , m

- J j :

-

Job, j = 1, 2, . . . , n

- T ij :

-

Completion time of job j on machine i

- T j :

-

Time job j leaves a system

- T max :

-

Makespan

- N :

-

Source

- M :

-

Sink

- B :

-

Subset of selected disjunctive arcs

- v ij :

-

Processing time of job j on machine i

- v j :

-

Processing time of job j on any machines

- w ij :

-

Starting time of job j on machine i

- Z :

-

Set of all operations

- C :

-

Set of all routing constraints

References

David EG (1989) Genetic algorithms in search, optimization, and machine learning. Addison–Wesley Longman, Inc., Reading, 1–14

Hiromi H (2001) Genetic algorithms and program. Personal Media Corp. in Japanese: 169–194

Humio H, Tatsuo H, Toshiro K, Kiyoshi K (1993) Production control systems. Kyoritsu-Shuppan in Japanese: 98–120

Ichiro S, Masami K (2003) Decentralized probabilistic algorithm using a multi-agent system for vehicle routing problems. Int J Smart Eng Sys Des (5):241–249

Japan Mechanical Engineering Editing Committee (2004) Mechanical engineering handbook. Ohmsha in Japanese: 702–715

Junzo W (2004) Construction of consultation systems on descriptive knowledge. Soft Comput 8(10):676–680

Junzo W, Yoshiyuki Y (1997) Fuzzy switching regression model based on genetic algorithm. The 7th International Fuzzy Systems Association World Congress, Prague, Czech Republic: 113–118

Lixin W, Loo HL (2002) A simulation study on release, synchronization, and dispatching in MEMS fabrication. Proceedings of the 2002 Winner Simulation Conference: 1392–1400

Michael P (2002) Scheduling, theory, algorithms, and systems. Prentice-Hall, Englewood Cliffs: 156–185

Toshio S, Kazunori M (2003) Hydraulic and pneumatic circuits. Ohmsha in Japanese: 200–213

Yuken Catalogue (2004) Series hydraulic cylinders in graph format. Yuken Kogyo Co., Ltd.: 601–661

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, I., Watada, J. & Shigaki, I. A comparison of dispatching rules and genetic algorithms for job shop schedules of standard hydraulic cylinders. Soft Comput 12, 121–128 (2008). https://doi.org/10.1007/s00500-007-0222-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-007-0222-7