Abstract

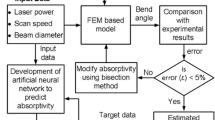

The present study focused on selecting optimal factors combination that causes maximum bending angle in laser bending of AA6061-T6. For this purpose a L\(_{25}\) Taguchi orthogonal design (four factors-five levels) is used to design experiments. Here, the process main factors are laser power, spot diameter, pulse duration and scanning speed and the main response was bending angle. To correlate relationship between process factors and bending angle, a radial basis function neural network (RBFNN) was utilized. Then the developed RBFNN model was used as an objective function for maximizing deformation through teaching–learning-based optimization algorithm. Results indicated that the laser power of 3.6 kW, spot diameter of 2 mm, pulse duration of 0.9 ms and scanning speed of 2 mm/s lead to maximal bending angle about 28.7\(^\circ \). Hereafter the optimal results have been verified by confirmatory experiments.

Similar content being viewed by others

References

Babajanzade-Roshan S, Behboodi-Jooibari M, Teimouri R, Asgharzade-Ahmadi G, Falahati-Naghibi M, Sohrabpoor H (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol. doi:10.1007/s00170-013-5131-6

Baseri H, Rahmani B, Bakhshi M (2011) Selection of bending parameters for minimal spring-back using an ANFIS model and simulated annealing algorithm. J Manuf Sci Eng ASME Trans. doi:10.1115/1.4004139

Cheng PJ, Lin SC (2000) Using neural network to predict bending angle sheet metal formed by laser. Int J Mach Tools Manuf 40:1185–1197

Gisario A, Barletta M, Conti C, Guarino S (2011) Spring back control in sheet metal bending: experimental analysis, empirical and neural network modeling. Opt Laser Eng 12:1372–1383

Hu Z, Labudovic M, Wang H, Kovacevic R (2001) Computer simulation and experimental investigation of sheet metal bending using laser beam scanning. Int J Mach Tools Manuf 41:589–607

Jung H-C (2006) A study on laser forming process with finite element analysis. Fulfilled PhD thesis in University of Canterbury from New Zealand

Kuar AS, Doloi B, Bhattacharyya B (2006) Modeling and analysis of pulsed Nd:YAG laser machining characteristics during micro-drilling of zirconia (ZrO\(_{2})\). Int J Mach Tools Manuf 46: 1301–1310

Maji K, Pratihar KD, Nath AK (2012) Experimental investigations and statistical analysis of pulsed laser bending of AISI 304 stainless steel sheet. Opt Laser Technol 49:18–27

Maji K, Pratihar KD, Nath AK (2014) Laser forming of a dome shaped surface: experimental investigations, statistical analysis and neural network modeling. Opt Laser Eng 53:31–42

Maji K, Pratihar KD, Nath AK (2012) Analysis and synthesis of laser forming process using neural networks and neuro-fuzzy inference system. Soft Comput. doi:10.1007/s00500-012-0949-7

Pawar PJ, Rao RV (2012) Parameter optimization of machining processes using teaching–learning-based optimization algorithm. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4524-2

Rao RV, Savsani VJ, Vakharia DP (2012) Teaching-learning-based optimization: an optimization method for continuous non-linear large scale problem information. Science 183:1–15

Rao RV, Patel V (2012) An elitist teaching-learning-based optimization algorithm for solving complex constrained optimization problems. Int J Ind Eng Comput 3:535–560

Rao RV, Kalyankar VD (2013) Parameter optimization of modern machining processes using teaching–learning-based optimization algorithm. Eng Appl Artif Intell 26:524–531

Safdar S, Li L, Sheikh MA, Liu Z (2007) Finite element simulation of laser tube bending: effects of scanning scheme on bending angle, distortions and stress distribution. Opt Laser Technol 39:1101–1110

Shen H, Vollertsen F (2009) Modelling of laser forming—an review. Comput Mater Sci 46(4):834–840

Sun J, Chan CC, Tan KM, Dong XY, Shum P (2007) Application of an artificial neural network for simultaneous measurement of bending curvature and temperature with long period fiber grating. Sens Actuators A Phys 137:262–267

Teimouri R, Baseri H (2012a) Improvement of dry EDM process characteristics using artificial soft computing methodologies. Prod Eng Res Dev. doi:10.1007/s11740-012-0398-2

Teimouri R, Baseri H (2012b) Artificial evolutionary approaches to produce smoother surface in magnetic abrasive finishing of hardened AISI 52100 steel. J Mech Sci Technol 27:533–539

Teimouri R, Baseri H (2013) Forward and backward predictions of the friction stir welding parameters using fuzzy-Artificial bee colony—imperialist competitive algorithm system. J Intell Manuf. doi:10.1007/s10845-013-0784-4

Teimouri R, Baseri H, Rahmani B, Bakhshi-Jooybari M (2012) Modeling and optimization of spring-back in bending process using multiple regression analysis and neural computation. Int J Mater Form. doi:10.1007/s12289-012-1117-4

Venkata Rao R, Kalyankar VD (2013) Multi-pass turning process parameter optimization using teaching–learning-based optimization algorithm. ScientiaIranica. doi:10.1016/j.scient.2013.01.002

Venkata Rao R, Patel V (2013) An improved teaching-learning-based optimization algorithm for solving unconstrained optimization problems. ScientiaIranica. doi:10.1016/j.scient.2012.12.005

Wang X, Weixing X, Chen H, Wang J (2008) Parameter prediction in laser bending of aluminum sheet. Front Mech Eng China 3:293–298

Yanjin G, Sheng S, Guoqun Z, Yiguo L (2003) Finite element modeling of pre-loaded sheet metals. J Mater Process Technol 142:400–407

Zhang L, Michaleris P (2004) Investigation of Lagrangian and Eulerianfininte element methods for modeling laser forming process. Finite Element Anal Des 40:383–405

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by M. J. Watts.

Appendix

Appendix

See Table 6.

Rights and permissions

About this article

Cite this article

Omidvar, M., Fard, R.K., Sohrabpoor, H. et al. Selection of laser bending process parameters for maximal deformation angle through neural network and teaching–learning-based optimization algorithm. Soft Comput 19, 609–620 (2015). https://doi.org/10.1007/s00500-014-1282-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-014-1282-0