Abstract

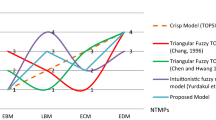

High-strength steel alloys, titanium, ceramics, composites are in the group of materials that are hard to machine. Conventional manufacturing techniques are not sufficient to machine these materials. For this reason, these materials are generally machined with non-conventional manufacturing methods. In this study, a fuzzy application of Best–Worst method and a novel hybrid decision-making model (Best–Worst decision-making approach with fuzzy TOPSIS) are proposed to solve different non-traditional machining method selection problems which were taken from the literature. Using these models, the Best–Worst method shortens the steps of solutions in the fuzzy environment compared to the AHP/ANP-based fuzzy solutions in the literature. The proposed models produce successful results.

Similar content being viewed by others

References

Arabzad SM, Ghorbani M, Razmi J, Shirouyehzad H (2015) Employing fuzzy TOPSIS and SWOT for supplier selection and order allocation problem. Int J Adv Manuf Technol 76:803–818

Avikal S, Jain R, Mishra P (2014) A Kano model. AHP and M-TOPSIS method based technique for disassembly line balancing under fuzzy environment. Appl Soft Comput 25:519–529

Azadnia AH, Saman MZM, Wong KY (2014) Sustainable supplier selection and order lot-sizing: An integrated multi-objective decision-making process. Int J Prod Res 53:1–26

Bagocˇius V, Zavadskas EK, Turskis Z (2014) Multi-person selection of the best wind turbine based on the multi-criteria integrated additive-multiplicative utility function. J Civ Eng Manag 20:590–599

Bagočius V, Zavadskas EK, Turskis Z (2013) Multi-criteria selection of a deep- water port in Klaipeda. Proc Eng 57:144–148

Bellman RE, Zadeh LA (1970) Decision making in a fuzzy environment. Manag Sci 17(4):141–164

Beskese A, Demir H, Ozcan H, Okten HE (2015) Landfill site selection using fuzzy AHP and fuzzy TOPSIS: a case study for Istanbul. Environ Earth Sci 73(3):513–3521

Boran FE, Genç S, Kurt M, Akay D (2009) A multi-criteria intuitionistic fuzzy group decision making for supplier selection with TOPSIS method. Expert Syst Appl 36:11363–11368

Buyurgan N, Saygin C (2008) Application of the analytical hierarchy process for real-time scheduling and part routing in advanced manufacturing systems. J Manuf Syst 27:101–110

Çalişkan H, Kurşuncu B, Kurbanoğlu C, Güven ŞY (2013) Material selection for the tool holder working under hard milling conditions using different multi criteria decision making methods. Mater Des 45:473–479

Chakladar ND, Chakraborty S (2008) A combined TOPSIS-AHP-method-based approach for non-traditional machining processes selection. Proc Inst Mech Eng-Part B: J Eng Manuf 222:1613–1623

Chakladar ND, Das R, Chakrabort S (2009) A digraph-based expert system for non-traditional machining processes selection. Int J Adv Manuf Technol 43(3–4):226–237

Chakraborty S, Dey S (1977) Design of an analytic-hierarchy-process-based expert system for non-traditional machining process selection. Int J Adv Manuf Technol 31(5–6):490–500

Chakroborty S, Dey S (2007) QFD-based expert system for non-traditional machining processes selection. Expert Syst Appl 32(4):1208–1217

Chang AY, Hu KJ, Hong Y-L (2013) An ISM-ANP approach to identifying key agile factors in launching a new product into mass production. Int J Prod Res 51:582–597

Chatterjee P, Chakraborty S (2012) Material selection using preferential ranking methods. Mater Des 35:384–393

Chatterjee P, Athawale VM, Chakraborty S (2009) Selection of materials using compromise ranking and outranking methods. Mater Des 30:4043–4053

Chatterjee P, Athawale VM, Chakraborty S (2011) Materials selection using complex proportional assessment and evaluation of mixed data methods. Mater Des 32:851–860

Chen CT (2000) Extensions of the TOPSIS for group decision making under fuzzy environment. Fuzzy Sets Syst 114:1–9

Dağdeviren M, Yavuz S, Kilinç N (2009) Weapon selection using the AHP and TOPSIS methods under fuzzy environment. Expert Syst Appl 36:8143–8151

Das S, Chakraborty S (2011) Selection of nontraditional machining processes using analytic network process. J Manuf Syst 30(1):41–53

Duran O, Aguilo J (2007) Computer-aided machine-tool selection based on a fuzzy-AHP approach. Expert Syst Appl 34(3):1787–1794

Hwang CL, Yoon K (1981) Multiple attribute decision making: methods and applications. Springer-Verlag, New York

İç YT, Yurdakul M, Eraslan E (2012) Development of a component-based machining centre selection model using AHP. Int J Prod Res 50:6489–6498

Jahan A, Edwards K (2013) VIKOR method for material selection problems with interval numbers and target-based criteria. Mater Des 47:759–765

Jahan A, Mustapha F, Ismail MY, Sapuan S, Bahraminasab M (2011) A comprehensive VIKOR method for material selection. Mater Des 32:1215–1221

Jana TK, Bairagi B, Paul S, Sarkar B, Saha J (2013) Dynamic schedule execution in an agent based holonic manufacturing system. J Manuf Syst 32:801–816

Kahraman C (2008) Multi-criteria decision making methods and fuzzy sets, fuzzy multi-criteria decision-making theory and applications with recent developments. Springer, New York, pp 1–20

Kaya T, Kahraman C (2010) Multicriteria renewable energy planning using an integrated fuzzy VIKOR & AHP methodology: The case of Istanbul. Energy. 35:2517–2527

Khorshidi R, Hassani A (2013) Comparative analysis between TOPSIS and PSI methods of materials selection to achieve a desirable combination of strength and workability in Al/SiC composite. Mater Des 52:999–1010

Krohling RA, Campanharo VC (2011) Fuzzy TOPSIS for group decision making: a case study for accidents with oil spill in the sea. Expert Syst Appl 38(4):4190–4197

Kul Y, Şeker A, Yurdakul M (2014) Usage of fuzzy multi criteria decision making methods in selection of nontraditional manufacturing methods. J Fac Eng Archit Gazi Univ 29(3):589–603

Kurt Ü (2014) The fuzzy TOPSIS and generalized Choquet fuzzy integral algorithm for nuclear power plant site selection–a case study from Turkey. J Nucl Sci Technol 51:1–15

Mardani A, Jusoh A, Nor K, Khalifah Z, Zakwan N, Valipour A (2015) Multiple criteria decision-making techniques and their applications—a review of the literature from 2000 to 2014. Econ Res-Ekonomska Istraživanja 28(1):516–571

Rajurkar KP, Ross RF (1992) The role of nontraditional manufacturing processes in future manufacturing industries. In: ASME manufacturing international, pp 23–37

Rezaei J (2015) Best-worst multi-criteria decision-making method. Omega 53:49–57

Sengul U, Eren M, Shiraz SE, Gezder V, Sengul AB (2015) Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew Energy 75:617–625

Streimikiene D, Balezentis T, Krisciukaitienė I, Balezentis A (2012) Prioritizing sustainable electricity production technologies: MCDM approach. Renew Sustain Energy Rev 16:3302–3311

Tzeng GH, Huang CY (2012) Combined DEMATEL technique with hybrid MCDM methods for creating the aspired intelligent global manufacturing and logistics systems. Ann Oper Res 197:159–190

Yao YL, Cheng JG, Rajurkar KP, Kovacecic R, Feiner S, Zhang W (2005) Combined research and curriculum development of nontraditional manufacturing. Eur J Eng Educ 30(3):363–376

Yurdakul M (2004) AHP as a strategic decision-making tool to justify machine tool selection. J Mater Process Technol 146:365–376

Yurdakul M, Çoğun C (2003) Development of a multi-attribute selection procedure for non-traditional machining processes. Proc Instit Mech Eng-Part B: J Eng Manuf 217:993–1009

Yurdakul M, İç YT (2009) Application of correlation test to criteria selection for multi criteria decision making (MCDM) models. Int J Adv Manuf Technol 40:403–412

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353

Zimmermann HJ, Zysno P (1985) Quantifying vagueness in decision models. Eur J Oper Res 22(2):148–158

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares there is no conflict of interest.

Human and animal rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Communicated by V. Loia.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Tables 23, 24, 25, 26 and 27.

Rights and permissions

About this article

Cite this article

Sofuoğlu, M.A. Fuzzy applications of Best–Worst method in manufacturing environment. Soft Comput 24, 647–659 (2020). https://doi.org/10.1007/s00500-019-04491-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-019-04491-5