Abstract

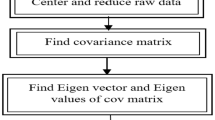

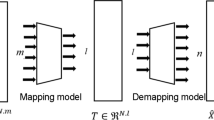

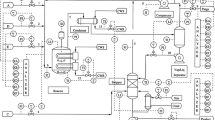

This paper describes the application of an improved nonlinear principal component analysis (PCA) to the detection of faults in polymer extrusion processes. Since the processes are complex in nature and nonlinear relationships exist between the recorded variables, an improved nonlinear PCA, which incorporates the radial basis function (RBF) networks and principal curves, is proposed. This algorithm comprises two stages. The first stage involves the use of the serial principal curve to obtain the nonlinear scores and approximated data. The second stage is to construct two RBF networks using a fast recursive algorithm to solve the topology problem in traditional nonlinear PCA. The benefits of this improvement are demonstrated in the practical application to a polymer extrusion process.

Similar content being viewed by others

References

Dong D, McAvoy TJ (1996) Nonlinear principal component analysis-based on principal curves and neural networks. Comput Chem Eng 20(1):65–78

Ge Z, Song Z (2007) Process monitoring based on independent component analysis-principal component analysis (ICA-PCA) and similarity factors. Ind Eng Chem Res 46(7):2054–2063

Ge Z, Song Z (2008) Online monitoring of nonlinear multiple mode processes based on adaptive local model approach. Control Eng Practice 16(12):1427–1437

Ge Z, Yang C, Song Z (2009) Improved kernel pca-based monitoring approach for nonlinear processes. Chem Eng Sci 64(9):2245–2255

Hastie TJ, Stuetzle W (1989) Principal curves. J Am Stat Assoc 84:502–516

He QP, Qin SJ, Wang J (2005) A new fault diagnosis method using fault directions in fisher discriminant analysis. AIChE J 51(2):555–571

Hinton GE, Salakhutdinov RR (2006) Reducing the dimensionality of data with neural networks. Science 313(5786):504–507

Jackson JE (1991) A users guide to principal components. Wiley Series in Probability and Mathematical Statistics, New York

Kramer MA (1991) Nonlinear principal component analysis using autoassociative neural networks. AIChE J 37(3):233–243

Lane S, Martin EB, Morris AJ, Gower P (2003) Application of exponentially weighted principal component analysis for the monitoring of a polymer film manufacturing process. Trans Inst Measure Control 25(1):17–35

Lennox B, Montague GA, Frith AM, Gent C, Bevan V (2001) Industrial application of neural networks—an investigation. J Process Control 11(5):497–507

Li K, Peng J, Irwin GW (2005) A fast nonlinear model identification method. IEEE Trans Automat Control 50(8):1211–1216

Li K, Peng JX, Bai EW (2006) A two-stage algorithm for identification of nonlinear dynamic systems. Automatica 42(7):1189–1197

Liu X, Xie L, Kruger U, Littler T, Wang S (2008) Statistical-based monitoring of multivariate non-Gaussian systems. AIChE J 54(9):2379–2391

Liu X, Li K, McAfee M, Deng J (2010) Improved nonlinear PCA based on RBF networks and principal curves. In: Proceedings of the 2010 international conference on life system modeling and and intelligent computing, and 2010 international conference on Intelligent computing for sustainable energy and environment: Part I. Springer, Berlin, LSMS/ICSEE’10, pp 7–15

Liu X, Li K, McAfee M, Irwin GW (2011) Improved nonlinear PCA for process monitoring using support vector data description. J Process Control (submitted)

McAfee M, Thompson S (2007) A novel approach to dynamic modelling of polymer extrusion for improved process control. Proc Inst Mech Eng I J Syst Control 221(4):617–628

Peng JX, Li K, Huang DS (2006) A hybrid forward algorithm for RBF neural network construction. IEEE Trans Neural Netw 17(6):1439–1451

Qin SJ, Valle S, Piovoso MJ (2001) On unifying multiblock analysis with application to decentralized process monitoring. J Chemometr 15(9):715–742

Rauwendaal C (2000) SPC: statistical process control in injection molding and extrusion (2nd edn). Carl Hanser Verlag, Munich

Rauwendaal C (2001) Polymer extrusion (4th edn). Carl Hanser Verlag, Munich

Scholkopf B, Smola AJ, Muller KR (1998) Nonlinear component analysis as a kernel eigenvalue problem. Neural Comput 10:1299–1399

Valle S, Qin S, Piovoso M (2001) Extracting fault subspaces for fault identification of a polyester film process. In: American control conference, 2001. Proceedings of the 2001

Weighell M, Martin E, Morris A (1997) Fault diagnosis in industrial process manufacturing using mspc. In: Fault diagnosis in process systems, IEEE colloquium on, pp 4/1–4/3

Weighell M, Martin E, Morris A (2001) The statistical monitoring of a complex manufacturing process. J Appl Stat 28(3):409–425

Yoon S, MacGregor JF (2000) Statistical and causal model-based approaches to fault detection and isolation. AIChE J 46(9):1813–1824

Zhang J, Zhao SJ, Xu YM (2006) Performance monitoring of processes with multiple operating modes through multiple PLS models. J Process Control 16(7):763–772

Acknowledgments

This work was financially supported by Engineering and Physical Sciences Research Council (EPSRC) under grant number EP/F021070/1. The experimental equipment was supplied by the Polymer Processing Research Centre, School of Mechanical and Aerospace Engineering, Queen’s University Belfast. The authors would like to thank the staff of the Centre for their time and help, particularly Dr. Gerry McNally, Mr. Alan Clarke, and Mr. Graham Garrett. The support provided by ‘Cherry Pipes Ltd’ is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Li, K., McAfee, M. et al. Application of nonlinear PCA for fault detection in polymer extrusion processes. Neural Comput & Applic 21, 1141–1148 (2012). https://doi.org/10.1007/s00521-011-0581-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-011-0581-y