Abstract

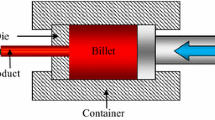

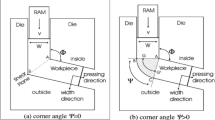

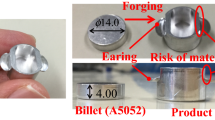

Selection of processing and geometrical parameters is a crucial step in the extrusion process design. Optimized parameters may result in desirable microstructure at minimum load. The purpose of this paper is determination of the optimal cold forward extrusion parameters with the minimization of tool load as the objective function. This paper deals with different optimization approaches in order to determine the optimal values of logarithmic strain, die angle, and friction with the purpose of finding the minimal tool loading obtained by cold forward extrusion process. The obtained extrusion force model as a fitness function was used to carry out the optimization. Based upon the objective function, metaheuristic algorithms such as genetic algorithm and simulated annealing were adopted as optimization methods for finding the optimum values of cold forward extrusion parameters and the obtained results were compared with those in literature. The better results lead to the smallest energy consumption, longer tool life, better formability of the work material, and the quality of the finished product.

Similar content being viewed by others

References

Kuzman K (2001) Problems of accuracy control in cold forming. J Mater Process Technol 113:10–15

Byon SM, Hwang SM (2003) Die shape optimal design in cold and hot extrusion. J Mater Process Technol 138:316–324

Jurkovic M, Jurkovic Z, Cukor G (2005) Genetic algorithm application in optimization of extrusion forming process. 10th International scientific conference on production engineering, CIM, Lumbarda

Yanran Z, Wang ZR, Weimin C (1995) Numerical simulations for extrusion and ironing and die-angle optimization. J Mater Process Technol 55:48–52

Pathak KK, Ramakrishnan N (2007) Optimization of die angle and ram velocity for rod extrusion using dynamic material modeling and genetic algorithm. Indian J Eng Mater Sci 14:399–402

Noorani-Azad M, Bakhshi-Jooybari M, Hosseinipour SJ, Gorji A (2005) Experimental and numerical study of optimal die profile in cold forward rod extrusion of aluminum. J Mater Process Technol 164–165:1572–1577

Jurkovic Z, Jurkovic M, Buljan S (2006) Optimization of extrusion force prediction model using different techniques. J Achieve Mater Manuf Eng 17:353–356

Jurkovic Z, Brezočnik M, Grizelj B, Mandić V (2009) Optimization of extrusion process by genetic algorithm and conventional techniques. Tech Gazette 16:27–33

Lange K (1985) Handbook of metal forming. McGraw-Hill, New York

Jurkovic M (1999) Mathematical modelling and optimization of machining processes. Dissertation, University of Rijeka

Montgomery DC (2003) Design and analysis of experiments, 5th edn. Wiley, New York

Brezocnik M, Kovacic M, Ficko M (2004) Intelligent systems for next-generation manufacturing. Acad J Manuf Eng 2(1):34–37

Jurkovic Z (2002) Modelling and simulation of tool loading by machining processes. Master thesis University of Rijeka

Jurkovic Z, Jurkovic M (1999) Mathematical modelling and minimization of force in cold forward extrusion process. Proceedings of the 2nd international conference on industrial tools ICIT’99 maribor

Abuelnaga AM, El-Dardiry MA (1984) Optimization methods for metal cutting. Int J Mach Tool Des Res 24:11–18

Rao SS (1996) Engineering optimization: theory and practice, 3rd edn. Wiley-Interscience, New York

Elbeltagi E, Hegazy T, Grierson D (2005) Comparison among five evolutionary-based optimization algorithms. Adv Eng Inform 19:43–53

Youssef H, Sait SM, Adiche H (2001) Evolutionary algorithms, simulated annealing and tabu search: a comparative study. Eng Appl Artif Intell 14:167–181

[20] Areibi S, Moussa M, Abdullah H (2001) A comparison of genetic/memetic algorithms and other heuristic search techniques, ICAI, Las VeGAs, Nevada

Giraud-Moreau L, Lafon P (2002) Comparison of evolutionary algorithms for mechanical design components. Eng Optim 34:307–322

Stoić A, Kopač J, Cukor G (2005) Testing of machinability of mould stell 40CrMnMo7 using genetic algorithm. J Mater Process Technol 164–165:1624–1630

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments, 2nd edn. Wiley-Interscience, New York

Brezocnik M, Kovacic M, Ficko M (2004) Prediction of surface roughness with genetic programming. J Mater Process Technol 157–158:28–36

Lee MK, Kwon KB (2006) Cutting path optimization in CNC cutting processes using a two-step genetic algorithm. Int J Prod Res 44:5307–5326

Jurkovic Z (2007) Modeling and optimization of the cutting parameters using evolutionary algorithms at the intelligent machining systems. Dissertation, University of Rijeka

Fleischer M (1995) Simulated annealing: past, present, and future. In IEEE, Arlington, pp 155–161

Kirkpatrick S, Gellat CD Jr, Vecchi MP (1983) Optimization by simulated annealing. Science 220(4598):671–680

Davidson R, Harel D (1996) Drawing graphs nicely using simulated annealing. ACM Trans Graphics 15:301–331

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadollah, A., Bahreininejad, A. Optimization of die design using metaheuristic methods in cold forward extrusion process. Neural Comput & Applic 21, 2071–2076 (2012). https://doi.org/10.1007/s00521-011-0630-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-011-0630-6