Abstract

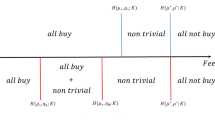

In today’s market conditions, volume of demand is quite uncertain and thus it is hard to estimate. In many cases, buyer is prone to use supply chain flexibility rather than inventory holding strategy to withstand demand uncertainty. We assume that the buyer releases a replenishment order to the supplier for each cycle (or period) under the contract which is mainly composed of four parameters: (1) supply cost per unit, (2) minimum order quantity, (3) order quantity reduction penalty and (4) maximum capacity of the supplier. Based on these parameters, there are two flexibility options that buyer should evaluate in the order of cycle (1) issue an order smaller than the minimum order quantity and pay the related penalty and (2) place no order and lose the sales. Hence, Q lost emerges as a critical buyer decision, the order quantity, below which no order is placed. Total expected supply cost plus lost sales, as a function of Q lost is presented. We derive the optimal Q lost that minimises the total cost function. Since capacity of each supplier is finite, we then develop a supplier selection model with total cost minimisation over the suppliers subject to capacity constraint that has a stochastic nature stemming from demand behaviour. Linearisation on the model is performed using chance-constrained programming approach. From a given set of supply bids from the potential supply chain partners, the buyer is able to make a quantifiable choice.

Similar content being viewed by others

References

Agrawal N, Smith SA, Tsay AA (2002) Multi-vendor sourcing in a retail supply chain. Prod Oper Manag 11(2):157–182

Beamon BM (1999) Measuring supply chain performance. Int J Oper Prod Manag 19(3):275–292

Bendre AB, Thorstenson A (2008) Evaluation of performance approximations for (r, q) inventory policies in a lost-sales setting. In: Proceedings international conference on flexible supply chains in a global economy, Molde University College

Braglia M, Petroni A (2000) A quality assurance-oriented methodology for handling tradeoffs in supplier selection. Int J Phys Distrib & Logist Manag 30(2): 96–111

Corsten D, Gruen T (2004) Stockouts cause walkouts. Harv Bus Rev 82(5):26–28

Das SK, Abdel-Malek L (2003) Modeling the flexibility of order quantities and lead-times in supply chain. Int J Prod Econ 85(2):171–181

Das K (2011) Integrating effective flexibility measures into a strategic supply chain planning model. Eur J Oper Res 211(1):170–183

Duclos LK, Wokukra RJ, Lummus RR (2003) A conceptual model of supply chain flexibility. Ind Manag Data Syst 103(6):446–456

Gerwin D (1993) Manufacturing flexibility: a strategic perspective. Manage Sci 39(4):395–410

Gosling J, Purvis L, Naim MM (2010) Supply chain flexibility as a determinant of supplier selection. Int J Prod Econ 128(1):11–21

Gupta YP, Somers TM (1992) The measurement of manufacturing flexibility. Eur J Oper Res 60(2):166–182

Kesen SE, Kanchanapiboon A, Das SK (2010) Evaluating supply chain flexibility with order quantity constraints and lost sales. Int J Prod Econ 126(2):162–169

Liao Z, Rittscher J (2007) A multi-objective supplier selection model under stochastic demand conditions. Int J Prod Econ 105(1):150–159

Lummus RR, Duclos LK, Vokukra RJ (2003) Supply chain flexibility: building a new model. Glob J Flex Syst Manag 4(4):1–13

Mascarenhas B (1981) Planning for flexibility. Long Range Plan 14(5):78–82

Moon KK-L, Yi CY, Ngai EWT (2012) An instrument for measuring supply chain flexibility for the textile and clothing companies. Eur J Oper Res 222(2):191–203

Nagarur N (1992) Some performance measure of flexible manufacturing systems. Int J Prod Res 30(4):799–809

Pujawan IN (2004) Assessing supply chain flexibility: a conceptual framework and case study. Int J Integr Supply Manag 1(1):79–97

Slack N (1983) Flexibility as a manufacturing objective. Int J Prod Oper Manag 3(3):4–13

Smithson M (2003) Confidence intervals. Quantitative applications in the social sciences. Series No. 140. SAGE Publications, Belmont

Upton DM (1994) The management of manufacturing flexibility. Calif Manag Rev 36(2):72–89

Wickery S, Calantone R, Dröge C (1999) Supply chain flexibility: an empirical study. J Supply Chain Manag 35(3):16–24

Wokurka RJ, O’Leary-Kelly SW (2000) A review of empirical research on manufacturing flexibility. J Oper Manag 18(4):485–501

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Deriving the Ωqty penalty

Appendix 2: Deriving the Ωlost penalty

Appendix 3: Deriving optimal Qlost

Since \( \Upomega^{''} (a) < 0 \) for all problem setting, \( Q_{lost}^{[1]} = a \) is the maximum point for the total cost function Ω.

Since \( \Upomega^{''} \left( {\frac{{\beta Q_{{\min} } }}{\beta + \gamma }} \right) > 0 \) for all problem setting, \( Q_{{\rm lost}}^{[2]} = \frac{{\beta Q_{{\min} } }}{\beta + \gamma } \) is the minimum point for the total cost function Ω.

Appendix 4: GAMS/Cplex codes for supplier selection model

sets |

i supplier/I-1*I-5/; |

scalar a lower bound of distribution/700/ |

c mode of distribution/1600/ |

b upper bound of distribution/3000/ |

SP sale price /8/ |

GD confidence level /0.05/ ; |

parameter Mu mean; |

Mu = (a + b + c)/3; |

parameter StdSap Standard deviation; |

StdSap = sqrt((sqr(a) + sqr(b) + sqr(c) − a*b − a*c − b*c)/18); |

parameter Z; |

Z = (b − sqrt(GD*(b − a)*(b − c)) − Mu)/StdSap; |

parameters Qmin(i) minimum order quantity/ |

I-1 1300 |

I-2 1220 |

I-3 1240 |

I-4 1205 |

I-5 1270/; |

parameters Ca(i) maximum capacity of each supplier/ |

I-1 2000 |

I-2 1800 |

I-3 2100 |

I-4 1770 |

I-5 1800/; |

parameters Beta(i) maximum quantity reduction penalty/ |

I-1 35000 |

I-2 38000 |

I-3 33000 |

I-4 43000 |

I-5 30000/; |

parameter Alfa(i); |

Alfa(i) = SP*Qmin(i); |

parameter Qlost(i) optimum lost sales; |

Qlost(i) = (a*(Beta(i) + Alfa(i)) + Beta(i)*Qmin(i) + sqrt(sqr(a)*sqr(Beta(i) + Alfa(i)) + sqr(Beta(i)*Qmin(i)) − 2*a*Beta(i)*(Beta(i) + Alfa(i))*Qmin(i)))/(2*(Beta(i) + Alfa(i))); |

parameter QRP(i) quantity reduction penalty; |

QRP(i) = (2*Beta(i)/((b − a)*(c − a)))*(sqr(Qmin(i))/6 − a*Qmin(i)/2 + a*Qlost(i) − sqr(Qlost(i))/2 − a*sqr(Qlost(i))/(2*Qmin(i)) + power(Qlost(i),3)/(3*Qmin(i))); |

parameter LSP(i) lost sales penalty; |

LSP(i) = (2*Alfa(i)/((b − a)*(c − a)*Qmin(i)))*(power(Qlost(i),3)/3 − a*sqr(Qlost(i))/2 + power(a,3)/6); |

parameter TC(i) total cost; |

TC(i) = QRP(i) + LSP(i); |

variables |

af objective function |

X(i) proportion of demand that is assigned to each supplier; |

positive variable |

X(i); |

Equations |

ObjFun objective function value which is minimised |

Eq1 |

Eq2; |

ObjFun.. af = e = sum(i,TC(i)*X(i)); |

Eq1.. sum(i,X(i)) = e = 1; |

Eq2(i).. X(i)*Mu+Z*X(i)*StdSap = l = Ca(i); |

model SSM/all/; |

solve SSM using lp minimizing af; |

display Qlost, Z, Mu, StdSap, QRP, LSP, TC; |

Rights and permissions

About this article

Cite this article

Kesen, S.E. Capacity-constrained supplier selection model with lost sales under stochastic demand behaviour. Neural Comput & Applic 24, 347–356 (2014). https://doi.org/10.1007/s00521-012-1226-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1226-5