Abstract

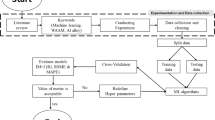

Welding processes are considered as an essential component in most of industrial manufacturing and for structural applications. Among the most widely used welding processes is the shielded metal arc welding (SMAW) due to its versatility and simplicity. In fact, the welding process is predominant procedure in the maintenance and repair industry, construction of steel structures and also industrial fabrication. The most important physical characteristics of the weldment are the bead geometry which includes bead height and width and the penetration. Different methods and approaches have been developed to achieve the acceptable values of bead geometry parameters. This study presents artificial intelligence techniques (AIT): For example, radial basis function neural network (RBF-NN) and multilayer perceptron neural network (MLP-NN) models were developed to predict the weld bead geometry. A number of 33 plates of mild steel specimens that have undergone SMAW process are analyzed for their weld bead geometry. The input parameters of the SMAW consist of welding current (A), arc length (mm), welding speed (mm/min), diameter of electrode (mm) and welding gap (mm). The outputs of the AIT models include property parameters, namely penetration, bead width and reinforcement. The results showed outstanding level of accuracy utilizing RBF-NN in simulating the weld geometry and very satisfactorily to predict all parameters in comparison with the MLP-NN model.

Similar content being viewed by others

References

Acosta FMA (1995) Radial basis function and related models: an overview. Signal Process 45:37–58

Akrami SA et al (2014) Rainfall data analyzing using moving average (MA) model and wavelet multi-resolution intelligent model for noise evaluation to improve the forecasting accuracy. Neural Comput Appl 25(7–8):1853–1861

Al-Faruk A, Hasib MDA, Ahmed N, Kumar Das U (2014) Prediction of weld bead geometry and penetration on electric arc welding using artificial neural networks. Int J Mech Mech Eng IJMME-IJENS 10(4):19–23

Baymani M, Effati S, Niazmand H, Kerayechian A (2015) Artificial neural network method for solving the Navier–Stokes equations. Neural Comput Appl 26(4):765–773

Benyounis KY, Olabi AG (2008) Optimization of different processes using statistical and numerical approaches—a reference guide. Adv Eng Softw 39:483–496

Bradstreet BJ (1969) Effect of welding conditions on cooling rate and hardness in the heat affected zone. Weld J Am Weld Soc 48(11):499-S–504-S

Cary H (1988) Welding technology, 2nd edn. Prentice Hall, Upper Saddle River

Cowper MR, Mulgrew B, Unsworth CP (2002) Nonlinear prediction of chaotic signals using a normalized radial basis function network. Signal Process 82:775–789

El-Shafie A, Abdelazim T, Noureldin A (2010) Neural network modeling of time-dependent creep deformations in masonry structures. Neural Comput Appl 19(4):583–594

El-Shafie A, Najah A, Karim OA (2014) Amplified wavelet-ANFIS-based model for GPS/INS integration to enhance vehicular navigation system. Neural Comput Appl 24(7–8):1905–1916

Elzwayie A et al (2016) RBFNN-based model for heavy metal prediction for different climatic and pollution conditions. Neural Comput Appl 1–13. doi:10.1007/s00521-015-2174-7

Fayaed SS, El-Shafie A, Jaafar O (2013) Adaptive neuro-fuzzy inference system-based model for elevation–surface area–storage interrelationships. Neural Comput Appl 22(5):987–998

Hossain MS, El-Shafie A (2014) Evolutionary techniques versus swarm intelligences: application in reservoir release optimization. Neural Comput Appl 24(7–8):1583–1594

Hossain MS, El-shafie A (2014) Performance analysis of artificial bee colony (ABC) algorithm in optimizing release policy of Aswan High Dam. Neural Comput Appl 24(5):1199–1206

Khanna OP (2006) A text book of welding technology. Dhanpat Rai Publications Ltd., Delhi

Kim DW, Kim KH, Jang W, Frank Chen F (2002) Unrelated parallel machines scheduling with setup times using simulated annealing. Robot Comput Integr Manuf 18(3–4):223–231

Kolahan F, Heidari M (2010) A new approach for predicting and optimizing weld bead geometry in GMAW. Int J Mech Syst Sci Eng 2(2):138–142

Kostić S, Vasović D (2015) Prediction model for compressive strength of basic concrete mixture using artificial neural networks. Neural Comput Appl 26(5):1005–1024

Kumar A, Chauhan V, Bist AS (2013) Role of artificial neural network in welding technology: a survey. Int J Comput Appl 67(1):32–37

Mollah AA, Pratihar DK (2007) Modeling of TIG welding and abrasive flow machining processes using radial basis function networks. Int J Adv Manuf Technol (2008) 37:937–952

Nagesh DS, Datta GL (2002) Prediction of weld geometry and penetration in shielded metal-arc welding using artificial neural networks. J Mater Process Technol 123:303–312

Najah A, El-Shafie A, Karim OA, Jaafar O (2011) Integrated versus isolated scenario for prediction dissolved oxygen at progression of water quality monitoring stations. Hydrol Earth Syst Sci 15:2693–2708

Najah AA, El-Shafie A, Karim OA, Jaafar O (2012) Water quality prediction model utilizing integrated wavelet-ANFIS model with cross-validation. Neural Comput Appl 21(5):833–841

Najah A et al (2013) Application of artificial neural networks for water quality prediction. Neural Comput Appl 22(SUPPL.1):187–201

Nash JE, Sutcliffe JV (1970) River flow forecasting through conceptual model. Part 1—A discussion of principles. J Hydrol 10:282–290

Pal S, Pal SK, Samantaray AK (2008) Artificial neural network modeling of weld joint strength prediction of a pulsed metal inert gas welding process using arc signals. J Mater Process Technol 202:464–474

Palani PK, Murugan N (2007) Optimization of weld bead geometry for stainless steel claddings deposited by FCAW. J Mater Process Technol 190:291–299

Shi Y, Zheng Z, Huang J (2013) Sensitivity model for prediction of bead geometry in underwater wet flux cored arc welding. Trans Nonferr Met Soc China 23:1977–1984

Singh RP, Gupta RC, Sarkar SC (2012) Prediction of weld bead geometry in shielded metal arc welding under external magnetic field using artificial neural networks. Int J Manuf Technol Res 8(1):9–15

Talib F, Rahman Z (2010) Critical success factors of total quality management in service organization: a proposed model. Serv Mark Q 31(3):363–380

Yaseen ZM et al (2015) RBFNN versus FFNN for daily river flow forecasting at Johor River. Malaysia, Neural Comput Appl

Yousif YK, Daws DM, Kazem BI (2008) Prediction of friction stir welding characteristic using neural network. Jordan J Mater Ind Eng 2(3):151–155

Acknowledgments

This research was supported by the research Grant for the four authors from University Kebangsaan Malaysia DLP-2015-012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmed, A.N., Noor, C.W.M., Allawi, M.F. et al. RBF-NN-based model for prediction of weld bead geometry in Shielded Metal Arc Welding (SMAW). Neural Comput & Applic 29, 889–899 (2018). https://doi.org/10.1007/s00521-016-2496-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2496-0