Abstract

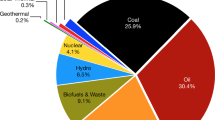

In this paper, a new type of low-pressure steam generator, roots-type power machine, is proposed to solve the shortcomings of medium- and low-temperature waste heat energy recovery. The rotor is systematically studied by means of theoretical analysis, numerical simulation and experimental verification. Firstly, the motion law of roots-type power machine is analyzed theoretically. According to the rotor profile characteristics, the rotor profile structure is divided and the parameter equation is established. In order to verify the feasibility of the designed rotor, the pressure field, velocity field and mass flow field inside the roots-type power machine where the rotor is located are analyzed by numerical simulation method. Finally, a test platform is built to test the power output characteristics, load characteristics and flow characteristics of the roots-type power machine. The feasibility of the rotor profile design method and the reliability of the rotor mathematical model are verified. The results show that the design of the rotor profile can meet the power generation requirements of the roots-type power machine. The rotor profile design method provides a new idea and strong theoretical guidance and basis for the design of the rotor of the subsequent roots-type power machine. Moreover, the development of the roots-type power machine will have a profound impact on the recycling and energy saving of low-temperature waste heat resources.

Similar content being viewed by others

References

Shi T (2011) Establishment of a mathematic model of roots blower impellers. For Mach Woodwork Equip 395:31–33

Wang J, Liu K, Zheng C (2012) Construction of perfect meshing profile of rotors for roots blowe. Fluid Mach 405:30–33

Liu L, Chu J, Jianzhong H (2007) Study on profile of roots vacuum pump rotor. Mach Des 243:65–67

Ye X, Wang Y (1989) Deduction and calculation of the practical linear formula of roots pump rotor. Vacuum 5:49–54

Wu X, Zhou Y, Zheng Z et al (2017) Flow simulation and optimization of zinc pump by fluent software. Mod Ind Econ Inf 7(13):32–33

Yang DCH, Tong S (2002) The specific flowrate of deviation function based lobe pumps-derivation and analysis. Mech Mach Theory 3710:1025–1042

Wang ZY, Qi LI, Shi Y et al (2016) Research on the characteristics of contact lines and dynamic balance of a kind of twin screw vacuum pump rotor. Vacuum 53(1):32–36

Hsieh C, Hwang Y (2008) Tooth profile of a roots rotor with a variable trochoid ratio. Math Comput Model 482:19–33

Yanjun X, Chunxia L, Dayuan W (2014) Parameter design and performance analysis of roots-steam engine. Hydromechatron Eng 24:93–97

Kovacevic A (2010) Boundary adaptation in grid generation for CFD analysis of screw compressors. Int J Numer Meth Eng 64(3):401–426

Lemort V, Quoilin S, Cuevas C et al (2009) Testing and modeling a scroll expander integrated into an organic rankine cycle. Appl Therm Eng 29(14):3094–3102

Shen Y (2000) Process analysis and experimental investigation on a scroll expander. Cryog Eng 4:24–28

Liu Zhengxian X, Lianhuan ZX (2010) Unsteady numerical simulation and analysis of the flow fluctuation in the roots blower. J Aerosp Power 223:401–405

Cheng Z, Wang J, Wei S et al (2017) Optimization of gaseous fuel injection for saving energy consumption and improving imbalance of heat distribution in iron ore sintering. Appl Energy 207:230–242

Acknowledgements

This work was financially supported by Tianjin Science and Technology Project (15JCTPJC62400).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, Y., Kong, X., Wang, S. et al. Design and feasibility study of roots-type power machine rotor based on numerical simulation. Neural Comput & Applic 32, 223–234 (2020). https://doi.org/10.1007/s00521-018-3804-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-018-3804-7