Abstract

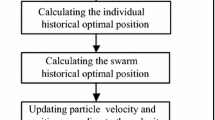

Assembly sequence planning is one of the key issues in DFA and computer-aided assembly process planning research for concurrent engineering. The purpose of this paper is to solve the problem of insufficient individual intelligence in evolutionary algorithms for assembly sequence planning, and a evolutionary algorithm for assembly sequence planning is designed. In this paper, the particle swarm optimization (PSO) algorithm is used to optimize the hybrid assembly sequence planning and assembly line balance problems. According to the assembly sequence problem, the number of assembly tool changes and the number of assembly orientation changes are transformed into the operation time of the assembly line. At the same time, the transportation of heavy parts in the assembly balance problem is considered. Then, by extracting the connection relationship and information of the parts, the disassembly method is used to inversely obtain the disassembly support matrix, and then, it is used to obtain the priority relationship diagram of the assembly operation tasks that indicate the order constraints of the job tasks on the assembly line. Aiming at the shortcoming that particle swarm optimization algorithm is easy to fall into local optimum, a various population strategy is adopted to shorten the evolution stagnation time, improve the evolution efficiency of particle swarm optimization algorithm, and enhance the optimization ability of the algorithm. Combined with the three evaluation indicators of assembly geometric feasibility, assembly process continuity, and assembly tool change times, a fitness function is constructed to achieve multi-objective optimization. Finally, experiments show that the multi-agent evolutionary algorithm is incorporated into the planning process to obtain an accurate solution through the various population strategy–particle swarm optimization algorithm, which proves the feasibility of the compound algorithm and has better performance in solving assembly sequence planning problems.

Similar content being viewed by others

References

Abdullah MA, Ab Rashid MFF, Ghazali Z (2019) A case study of energy efficient assembly sequence planning problem. In: IOP conference series materials science and engineering, vol 469, p 012013

Gunji AB, Deepak BBBVL, Bahubalendruni CMVAR (2018) An optimal robotic assembly sequence planning by assembly subsets detection method using teaching learning-based optimization algorithm. IEEE Trans Autom Sci Eng 15(3):1369–1385

Jiao Q, Xu D (2018) A discrete bat algorithm for disassembly sequence planning. J Shanghai Jiaotong Univ Sci 23(2):276–285

Ma H, Peng Q, Zhang J (2018) Assembly sequence planning for open-architecture products. Chin J Eng Des 94(2):1–14

Li Y, Wang H, Yang Z (2019) Type II assembly line balancing problem with multi-operators. Neural Appl 31:347–357

Wang D, Shao X, Liu H (2017) Assembly sequence planning for panels of reflector antenna based on hybrid algorithm. Comput Integr Manuf Syst 23(6):1243–1252

Castronovo F, Van Meter PN, Zappe SE (2017) Developing problem-solving skills in construction education with the virtual construction simulator. Int J Eng Educ 33(2):831–846

Son C (2015) Intelligent rule-based sequence planning algorithm with fuzzy optimization for robot manipulation tasks in partially dynamic environments. Inf Sci 342:209–221

Wang D, Shao X, Liu S (2017) Assembly sequence planning for reflector panels based on genetic algorithm and ant colony optimization. Int J Adv Manuf Technol 91(1–4):987–997

Xin L, Jianzhong S, Yujun C (2017) An efficient method of automatic assembly sequence planning for aerospace industry based on genetic algorithm. Int J Adv Manuf Technol 90(5–8):1–9

Zhang W, Ma M, Li H (2017) Generating interference matrices for automatic assembly sequence planning. Int J Adv Manuf Technol 90(1–4):1–15

Yavari M, Marvi M, Akbari AH (2020) Semi-permutation-based genetic algorithm for order acceptance and scheduling in two-stage assembly problem. Neural Comput Appl 32:2989–3003

Yu J, Zhang J (2017) Hierarchical exploded view generation based on recursive assembly sequence planning. Int J Adv Manuf Technol 93(6):1–22

Kheder M, Trigui M, Aifaoui N (2017) Optimization of disassembly sequence planning for preventive maintenance. Int J Adv Manuf Technol 90(5–8):1–13

Yu J, Wang J (2016) Automatic generation of hierarchical exploded view based on recursive iteration method. J Mech Eng 52(13):175–188

Song B, Wang Z, Sheng L (2016) A new genetic algorithm approach to smooth path planning for mobile robots. Assem Autom 36(2):138–145

Spensieri D, Carlson JS, Ekstedt F et al (2016) An iterative approach for collision free routing and scheduling in multirobot stations. IEEE Trans Autom Sci Eng 13(2):950–962

Hadj RB, Trigui M, Aifaoui N (2015) Integrated CAD approach for generating assembly sequence plans based on collision study results. Lecture Notes in Control & Information Sciences, vol 789, pp 63–72

Chou J-S, Pham A-D (2015) Smart artificial firefly colony algorithm-based support vector regression for enhanced forecasting in civil engineering. Comput-Aided Civ Infrastruct Eng 30(9):715–732

Zeng B, Li M, Zhang Y (2014) Assembly sequence planning based on improved firefly algorithm. Comput Integr Manuf Syst 20(4):799–806

Tang M, Chen S, Zheng X (2018) Sensors deployment optimization in multi-dimensional space based on improved particle swarm optimization algorithm. J Syst Eng Electron 29(5):969–982

Xu Y, Zhu C, Li C (2018) Field crop segmentation based on color coefficient reverse mutation particle swarm optimization algorithm. Trans Chin Soc Agric Eng 34(3):173–179

Li R, Huang J, Chen C (2018) Hybrid precoding scheme based on improved particle swarm optimization algorithm in mm Wave massive MIMO system. J Comput Appl 38(3):2365–2369

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no potential competing interests in our paper. And all authors have seen the manuscript and approved to submit to your journal. We confirm that the content of the manuscript has not been published or submitted for publication elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, Y., Mao, H. & Tang, X. Algorithms for solving assembly sequence planning problems. Neural Comput & Applic 33, 525–534 (2021). https://doi.org/10.1007/s00521-020-05048-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-020-05048-6