Abstract

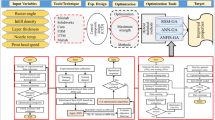

In designing fixtures for machining operations, clamping scheme is a complex and highly nonlinear problem that entails the frictional contact between the workpiece and the clamps. Such parameters as contact area, state of contact, clamping force, wear and damage in the contact area and deformation of the component are of special interest. A viable fixture plan must include the optimum values of clamping forces. Along research efforts carried out in this area, this comprehensive problem in fixture design needs further investigation. In this study, a hybrid learning system that uses nonlinear finite element analysis (FEA) with a supportive combination of artificial neural network (ANN) and genetic algorithm (GA) is discussed. A frictional model of workpart–fixture system under cutting and clamping forces is solved through FEA. Training and querying an ANN takes advantage of the results of FEA. The ANN is required to recognize a pattern between the clamping forces and state of contact in the workpiece–fixture system and the workpiece maximum elastic deformation. Using the identified pattern, a GA-based program determines the optimum values for clamping forces that do not cause excessive deformation/stress in the component. The advantage of this work against similar studies is manifestation of exact state of contact between clamp elements and workpart. The results contribute to automation of fixture design task and computer aided process planning (CAPP).

Similar content being viewed by others

References

H. Asada A. B. By (1985) ArticleTitleKinematic Analysis of Workpart Fixturing for Flexible Assembly with Automatically Reconfigurable Fixtures IEEE Journal of Robotics and Automation RA-1 IssueID2 86–94

DARPA Neural Network Study, (1988). AFCEA International Press, Fairfax, VA

E. C. De Meter (1994) ArticleTitleRestraint Analysis of Fixtures which Rely on Surface Contact ASME Journal of Engineering for Industry 116 207–215

E. C. De Meter W. Xi S. Choudhuri S. Vallapuzha M. Trethewey (2001) ArticleTitleA Model to Predict Minimum Required Clamp Pre-loads in Light of Fixture–Workpiece Compliance International Journal of Machine Tools and Manufacture 41 1031–1054

Hamedi, M. (2001). Fixture Design Optimization with Simulation of Clamp Tightness in Workpiece–Fixture System. Proceedings of the IASTED International Conference on Applied Simulation and Modeling, Spain

Y. Ishikawa T. Aoyama (1996) ArticleTitleOptimization of Fixturing Condition by Means of the Genetic Algorithm Transactions of Japanese Society of Mechanical Engineers Series C 65 IssueID598 2409–2416

P. Kohnke (1998) ANSYS version 5.6 User’s Manual ANSYS Inc. Canonsburg, PA

K. Krishnakumar S. N. Melkote (1999) ArticleTitleMachining Fixture Layout Optimization Using the Genetic Algorithm International Journal of Machine Tool Manufacture. 40 IssueID4 579–598

K. Kulankara S. Satyanarayana S. N. Melkote (2002) ArticleTitleInteractive Fixture Layout and Clamping Force Optimization Using the Genetic Algorithm ASME Journal of Manufacturing Science and Engineering 124 119–125

J. D. Lee L. S. Haynes (1987) ArticleTitleFinite Element Analysis of Flexible Fixturing Systems ASME Journal of Engineering for Industry 113 134–139 Occurrence Handle10.1115/1.3187103

R. O. Mittal (1991) ArticleTitleDynamic Modelling of the Fixture–Workpiece System Robotics and Computer-Integrated Manufacturing 8 IssueID4 201–217 Occurrence Handle1013764

A. Y. C. Nee A. Senthil Kumar (1991) ArticleTitleFramework for an Object/Rule-Based Fixture Design System Annals of the CIRP 40 147–151 Occurrence Handle10.1016/S0007-8506(07)61955-6

M. S. Ohwovoriole (1980) An Extension of Screw Theory and its Application to Automation of Industrial Assemblies Stanford University California

U. Roy J. Liao (2002) ArticleTitleFixturing Analysis for Stability Consideration in an Automated Fixture Design System ASME Journal of Manufacturing Science and Engineering 124 98–104

J. H. Yeh F. W. Liou (1999) ArticleTitleContact Condition Modelling for Machining Fixture Setup Processes International Journal of Machine Tools and Manufacture 39 787–803

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

HAMEDI, M. Intelligent Fixture Design through a Hybrid System of Artificial Neural Network and Genetic Algorithm. Artif Intell Rev 23, 295–311 (2005). https://doi.org/10.1007/s10462-004-7187-z

Issue Date:

DOI: https://doi.org/10.1007/s10462-004-7187-z