Abstract

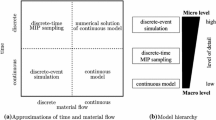

The paper deals with analytical modeling of transfer lines consisting of two machines decoupled by one finite buffer. In particular, the case in which a control policy (referred as “restart policy”) aiming to reduce the blocking frequency of the first machine is addressed. Such a policy consists of forcing the first machine to remain idle (it cannot process parts) each time the buffer gets full until it empties again. This specific behavior can be found in a number of industrial production systems, especially when some machines are affected by outage costs when stops occur. The two-machine one-buffer line is here modeled as a discrete time Markov process and the two machines are characterized by the same operation time. The analytical solution of the model is obtained and mathematical expressions of the most important performance measures are provided. Some significant remarks about the effect of the proposed restart policy on the behavior of the system are also pointed out.

Similar content being viewed by others

References

Altiok, T. M., & Stidham, S. (1983). The allocation of interstage buffer capacities in production lines. IIE Transactions, 15(4), 292–299.

Berman, O. (1982). Efficiency and production rate of a transfer line with two machines and a finite storage buffer. European Journal of Operational Research, 9, 295–308.

Bulgak, A. A., Diwan, P. D., & Inozu, B. (1995). Buffer size optimization in asynchronous assembly systems using genetic algorithms. Computers & Industrial Engineering, 28, 309–322.

Burman, M. H. (1995). New results in flow line analysis. Ph.D. thesis, Department of Electrical Engineering and Computer Science, Massachusetts Institute of Technology.

Buzacott, J. A. (1967). Markov chain analysis of automatic transfer line with buffer stock. Ph.D. thesis, University of Birmingham.

Buzacott, J. A. (1972). The effect of station breakdowns and random processing times on the capacity of flow lines with in-process storage. AIIE Transactions, 4(4), 308–312.

Buzacott, JA (1982). “Optimal” operating rules for automated manufacturing systems. IEEE Transactions on Automatic Control, Ac-27(1), 80–86.

Buzacott, J. A., & Hanifin, L. E. (1978). Models of automatic transfer lines with inventory banks: a review and comparison. AIIE Transactions, 10(2), 197–207.

Chiang, S. Y., Kuo, C. T., & Meerkov, S. M. (2000). DT-bottlenecks in serial production lines: theory and application. IEEE Transactions on Robotics and Automation, 16, 567–580.

Chiang, S. Y., Kuo, C. T., & Meerkov, S. M. (2001). c-Bottlenecks in serial production lines: identification and application. Mathematical Problems in Engineering, 7, 543–578.

Chiang, S. Y., Hu, A., & Meerkov, S. M. (2008). Lean buffering in serial production lines with nonidentical exponential machines. IEEE Transactions on Automation Science and Engineering, 5, 298–306.

Choong, Y. F., & Gershwin, S. B. (1989). A decomposition method for the approximate evaluation of capacitated transfer lines with unreliable machines and random processing times. IIE Transactions, 19, 150–159.

Dallery, Y., & Gershwin, S. B. (1992). Manufacturing flow line systems: a review of models and analytical results. Queueing Systems, 12, 3–94.

Dallery, Y., David, R. & Xie, X. L. (1989). Approximate analysis of transfer lines with unreliable machines and finite buffers. IEEE Transactions on Automatic Control, 34(9), 943–953.

Enginarlar, E., Li, J., & Meerkov, S. M. (2005). Lean buffering in serial production lines with non-exponential machines. OR Spectrum, 27, 195–219.

Gershwin, S. B. (1987). An efficient decomposition method for the approximate evaluation of tandem queues with finite storage space and blocking. Operations Research, 35(2), 291–305.

Gershwin, S. B. (2002). Manufacturing systems engineering. Massachusetts Institute of Technology. Second private printing, available via http://web.mit.edu/manuf-sys/www/gershwin.book.html.

Gershwin, S. B., & Berman, O. (1981). Analysis of transfer lines consisting of two unreliable machines with random processing times and finite storage buffers. AIIE Transactions, 13(1), 2–11.

Gershwin, S. B., & Burman, M. H. (2000). A decomposition method for analyzing inhomogeneous assembly/disassembly systems. Annals of Operations Research, 93, 91–115.

Gershwin, S. B., & Schick, I. C. (1980). Continuous model of an unreliable two-stage material flow system with a finite interstage buffer. Tech. rep. LIDS-R-1039, OSP No. 87049, Laboratory for Information and Decision Systems, Massachusetts Institute of Technology, Cambridge, MA 02139, USA.

Gershwin, S. B., & Schick, I. C. (1983). Modeling and analysis of three-stage transfer lines with unreliable machines and finite buffers. Operations Research, 31(2), 354–380.

Gershwin, S. B., & Schor, J. E. (2000). Efficient algorithms for buffer space allocation. Annals of Operations Research, 93, 117–144.

Gershwin, S. B., & Werner, L. M. (2007). An approximate analytical method for evaluating the performance of closed-loop flow systems with unreliable machines and finite buffers. International Journal of Production Research, 45(14), 3085–3111.

Heavey, C., Papadopoulos, H. T., & Browne, J. (1993). The throughput rate of multistation unreliable production lines. European Journal of Operational Research, 68, 69–89.

Hong, Y., & Seong, D. (1993). The analysis of an unreliable two-machine production line with random processing times. European Journal of Operational Research, 68, 228–235.

Kim, J., & Gershwin, S. B. (2005). Integrated quality and quantity modeling of a production line. OR Spectrum, 27(2–3), 287–314.

Koster, M. B. M. D. (1987). Estimation of line efficiency by aggregation. International Journal of Production Research, 25, 615–626.

Levantesi, R., Matta, A., & Tolio, T. (2003). Performance evaluation of continuous production lines with machines having different processing times and multiple failure modes. Performance Evaluation, 51, 247–268.

Lutz, C. M., Davis, K. R., & Sun, M. (1998). Determining buffer location and size in production lines using tabu search. European Journal of Operational Research, 106, 301–316.

Maggio, N., Matta, A., Gershwin, S. B., & Tolio, T. (2003). An approximate analytical method for evaluating the performance of closed loop flow systems with unreliable machines and finite buffers. Part I. Small loops. Tech. rep., Laboratory for Manufacturing and Productivity. Cambridge: Massachusetts Institute of Technology, MA 02139, USA.

Manitz, M. (2008). Queueing-model based analysis of assembly lines with finite buffers and general service times. Computers & Operations Research, 35, 2520–2536.

Papadopoulos, H. T., & Heavey, C. (1996). Queueing theory in manufacturing systems analysis and design: a classification of models for production and transfer lines. European Journal of Operational Research, 92, 1–27.

Papadopoulos, H. T., & Vidalis, M. I. (1998). Optimal buffer storage allocation in balanced reliable production lines. International Transactions in Operational Research, 5(4), 325–339.

Papadopoulos, H. T., & Vidalis, M. I. (1999). Optimal buffer allocation in short μ-balanced unreliable production lines. Computers & Industrial Engineering, 37, 691–710.

Papadopoulos, H. T., & Vidalis, M. I. (2001a). A heuristic algorithm for the buffer allocation in unreliable unbalanced production lines. Computers & Industrial Engineering, 41, 261–277.

Papadopoulos, H. T., & Vidalis, M. I. (2001b). Minimizing WIP inventory in reliable production lines. International Journal of Production Economics, 70, 185–197.

Papadapoulos, H., Heavey, C., & Browne, J. (1993). Queuing theory in manufacturing systems analysis and design. London: Chapman & Hall.

Schick, I. C. & Gershwin, S. B. (1978). Modeling and analysis of unreliable transfer lines with finite interstage buffers. In: Complex Material Handling and Assembly Systems, vol. VI, Report ESL-FR-834-6, Electronic Systems Laboratory, Massachusetts Institute of Technology, Cambridge, MA 02139, USA.

Spinellis, D. D., & Papadopoulos, C. T. (2000). A simulated annealing approach for buffer allocation in reliable production. Annals of Operations Research, 93, 373–384.

Tan, B., & Yeralan, S. (1997). Analysis of multistation production systems with limited buffer capacity. Part II. The decomposition method. Mathematical and Computer Modelling, 25(11), 109–123.

Tolio, T., Matta, A., & Gershwin, S. B. (2002). Analysis of two-machine lines with multiple failure modes. IIE Transactions, 34(1), 51–62.

Yeralan, S., & Tan, B. (1997). Analysis of multistation production systems with limited buffer capacity. Part I. The subsystem model. Mathematical and Computer Modelling, 25(7), 109–122.

Zimmern, B. (1956). Études de la propagation des arrêts aléatoires dans les chaînes de production. Revue de Statistque Applique‘e, 4, 85–104.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gebennini, E., Grassi, A., Fantuzzi, C. et al. Discrete time model for two-machine one-buffer transfer lines with restart policy. Ann Oper Res 209, 41–65 (2013). https://doi.org/10.1007/s10479-011-0868-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-011-0868-5