Abstract

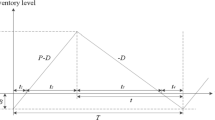

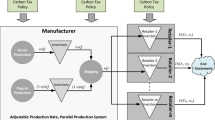

Faced with pressure from the public, governments, and environmental agencies, it is becoming essential for manufacturing firms to identify and implement sustainable operations aiming at reducing the negative social and environmental impacts while enhancing the firm’s public image and increasing its economic performance. This paper investigates a production model that incorporates the quality of different types of components/raw material parts used in the production process along with their transportation emissions tax. It is assumed that the various types of components contain both perfect and imperfect quality items. The percentage of perfect quality components of a particular type is a random variable having a known probability distribution. Based on results regarding the probability distribution and the expected value of the minimum of a set of random variables, a mathematical model is developed and the total production/inventory cost is obtained. A closed form formula approximating the optimal solution is derived in terms of the expected value of the minimum of a set of random variables related to the percentages of perfect quality components. The case in which the percentages of perfect quality components are uniformly distributed is investigated and a numerical example is given to illustrate this case. The accuracy of the approximated solution is assessed via a simulation algorithm that can also be used to approximate the optimal lot size in the case when the percentages of perfect quality components are not all uniformly distributed.

Similar content being viewed by others

References

Allevi, E., Gnudi, A., Konnov, I. V., & Oggioni, G. (2018). Evaluating the effects of environmental regulations on a closed-loop supply chain network: A variational inequality approach. Annals of Operations Research,261(1–2), 1–43.

Basu, R. J., Subramanian, N., Gunasekaran, A., & Palaniappan, P. L. K. (2017). Influence of non-price and environmental sustainability factors on truckload procurement process. Annals of Operations Research,250(2), 363–388.

Battini, D., Persona, A., & Sgarbossa, F. (2014). A sustainable EOQ model: Theoretical formulation and applications. International Journal of Production Economics,149, 145–153.

Bazan, E., Jaber, M. Y., & Zanoni, S. (2015). Supply chain models with greenhouse gases emissions, energy usage and different coordination decisions. Applied Mathematical Modelling,39(17), 5131–5151.

Bazan, E., Jaber, M. Y., & Zanoni, S. (2016). A review of mathematical inventory models for reverse logistics and the future of its modeling: An environmental perspective. Applied Mathematical Modelling,40(5–6), 4151–4178.

Bedworth, D. D., & Bailey, J. E. (1987). Integrated production control system management, analysis, design. New York, NY: Wiley.

Bonney, M., & Jaber, M. Y. (2011). Environmentally responsible inventory models: Non-classical models for a non-classical era. International Journal of Production Economics,133(1), 43–53.

Chen, W., & Hu, Z. H. (2018). Using evolutionary game theory to study governments and manufacturers’ behavioral strategies under various carbon taxes and subsidies. Journal of Cleaner Production,201, 123–141.

Du, S., Tang, W., Zhao, J., & Nie, T. (2016). Sell to whom? Firm’s green production in competition facing market segmentation. Annals of Operations Research, 270(1–2), 125–154.

Du, S., Zhu, Y., Zhu, Y., & Tang, W. (2017). Allocation policy considering firm’s time-varying emission reduction in a cap-and-trade system. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2606-0.

Dubey, R., Gunasekaran, A., Childe, S. J., Papadopoulos, T., Luo, Z., & Roubaud, D. (2017). Upstream supply chain visibility and complexity effect on focal company’s sustainable performance: Indian manufacturers’ perspective. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2544-x.

El Khalil, R., & El-Kassar, A. N. (2018). Effects of corporate sustainability practices on performance: The Case of the MENA Region. Benchmarking: An International Journal,25(5), 1333–1349.

El-Kassar, A. N. M. (2009, January). Optimal order quantity for imperfect quality items. In Allied academies international conference. Academy of Management Information and Decision Sciences. Proceedings (Vol. 13, No. 1, p. 24). Jordan Whitney Enterprises, Inc.

El-Kassar, A. N., Salameh, M., & Bitar, M. (2012). EPQ model with imperfect quality raw material. Mathematica Balkanica,26, 123–132.

Elluru, S., Gupta, H., Kaur, H., & Singh, S. P. (2017). Proactive and reactive models for disaster resilient supply chain. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2681-2.

Fahimnia, B., Sarkis, J., Gunasekaran, A., & Farahani, R. (2017). Decision models for sustainable supply chain design and management. Annals of Operations Research,250(2), 277–278.

Fu, H., Ma, Y., Ni, D., & Cai, X. (2017). Coordinating a decentralized hybrid push–pull assembly system with unreliable supply and uncertain demand. Annals of Operations Research,257(1–2), 537–557.

Ghosh, A., Jha, J. K., & Sarmah, S. P. (2017). Optimal lot-sizing under strict carbon cap policy considering stochastic demand. Applied Mathematical Modelling,44, 688–704.

Gurtu, A., Jaber, M. Y., & Searcy, C. (2015). Impact of fuel price and emissions on inventory policies. Applied Mathematical Modelling,39(3–4), 1202–1216.

Harris, F. W. (1913). How much stock to keep on hand. Factory. The Magazine of Management,10, 240–241.

Hayek, P. A., & Salameh, M. K. (2001). Production lot sizing with the reworking of imperfect quality items produced. Production Planning & Control,12(6), 584–590.

He, P., Zhang, W., Xu, X., & Bian, Y. (2015). Production lot-sizing and carbon emissions under cap-and-trade and carbon tax regulations. Journal of Cleaner Production,103, 241–248.

Jaber, M. Y. (Ed.). (2009). Inventory management: Non-classical views (pp. 43–74). New York: CRC Press.

Jawahar, N., Pandian, G. S., Gunasekaran, A., & Subramanian, N. (2017). An optimization model for sustainability program. Annals of Operations Research,250(2), 389–425.

Kaur, H., & Singh, S. P. (2016). Sustainable procurement and logistics for disaster resilient supply chain. Annals of Operations Research. https://doi.org/10.1007/s10479-016-2374-2.

Kaur, H., & Singh, S. P. (2017a). Flexible dynamic sustainable procurement model. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2434-2.

Kaur, H., & Singh, S. P. (2017b). Heuristic modeling for sustainable procurement and logistics in a supply chain using big data. Computers & Operations Research, 98, 301–321.

Khan, M., & Jaber, M. Y. (2011). Optimal inventory cycle in a two-stage supply chain incorporating imperfect items from suppliers. International Journal of Operational Research,10(4), 442–457.

Khan, M., Jaber, M. Y., Guiffrida, A. L., & Zolfaghari, S. (2011). A review of the extensions of a modified EOQ model for imperfect quality items. International Journal of Production Economics,132(1), 1–12.

Lamba, K., & Singh, S. P. (2018). Dynamic supplier selection and lot-sizing problem considering carbon emissions in a big data environment. Technological Forecasting and Social Change. https://doi.org/10.1016/j.techfore.2018.03.020.

Lamba, K., Singh, S. P., & Mishra, N. (2018). Integrated decisions for supplier selection and lot-sizing considering different carbon emission regulations in Big Data environment. Computers & Industrial Engineering. https://doi.org/10.1016/j.cie.2018.04.028.

Li, X. (2017). Optimal procurement strategies from suppliers with random yield and all-or-nothing risks. Annals of Operations Research,257(1–2), 167–181.

Mishra, D., Gunasekaran, A., Papadopoulos, T., & Childe, S. J. (2016). Big Data and supply chain management: a review and bibliometric analysis. Annals of Operations Research, 270(1–2), 313–336.

Munson, C. L., & Rosenblatt, M. J. (2001). Coordinating a three-level supply chain with quantity discounts. IIE Transactions,33(5), 371–384.

Porteus, E. L. (1986). Optimal lot sizing, process quality improvement and setup cost reduction. Operations Research,34(1), 137–144.

Rosenblat, M. J., & Lee, H. L. (1986). Economic production cycles with imperfect production processes. IIE Transactions,18, 48–55.

Salameh, M. K., & El-Kassar, A. N. (2007, March). Accounting for the holding cost of raw material in the production model. In Proceeding of BIMA inaugural conference (pp. 72–81).

Salameh, M. K., & Jaber, M. Y. (2000). Economic production quantity model for items with imperfect quality. International Journal of Production Economics,64(1–3), 59–64.

Sana, S. S. (2011). A production-inventory model of imperfect quality products in a three-layer supply chain. Decision Support Systems,50(2), 539–547.

Shibin, K. T., Dubey, R., Gunasekaran, A., Hazen, B., Roubaud, D., Gupta, S., & Foropon, C. (2017). Examining sustainable supply chain management of SMEs using resource based view and institutional theory. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2706-x.

Simpson, N. C. (2001). Questioning the relative virtues of dynamic lot sizing rules. Computers & Operations Research,28(9), 899–914.

Singh, S. K. (2018). Sustainable people, process and organization management in emerging markets. Benchmarking: An International Journal,25(3), 774–776.

Sinha, S., & Sarmah, S. P. (2010). Coordination and price competition in a duopoly common retailer supply chain. Computers & Industrial Engineering,59(2), 280–295.

Srivastav, A., & Agrawal, S. (2018). Multi-objective optimization of mixture inventory system experiencing order crossover. Annals of Operations Research. https://doi.org/10.1007/s10479-017-2744-4.

Taft, E. W. (1918). The most economical production lot. Iron Age,101(18), 1410–1412.

Taleizadeh, A. A. (2018). A constrained integrated imperfect manufacturing-inventory system with preventive maintenance and partial backordering. Annals of Operations Research,261(1–2), 303–337.

Taleizadeh, A. A., Tavakoli, S., & San-José, L. A. (2018). A lot sizing model with advance payment and planned backordering. Annals of Operations Research. https://doi.org/10.1007/s10479-018-2753-y.

Tayal, A., Gunasekaran, A., Singh, S. P., Dubey, R., & Papadopoulos, T. (2017). Formulating and solving sustainable stochastic dynamic facility layout problem: A key to sustainable operations. Annals of Operations Research,253(1), 621–655.

Wahab, M. I. M., Mamun, S. M. H., & Ongkunaruk, P. (2011). EOQ models for a coordinated two-level international supply chain considering imperfect items and environmental impact. International Journal of Production Economics,134(1), 151–158.

Wang, G., & Gunasekaran, A. (2017). Modeling and analysis of sustainable supply chain dynamics. Annals of Operations Research,250(2), 521–536.

Xia, L., Guo, T., Qin, J., Yue, X., & Zhu, N. (2017). Carbon emission reduction and pricing policies of a supply chain considering reciprocal preferences in cap-and-trade system. Annals of Operations Research, 268(1–2), 149–175.

Xia, L., Hao, W., Qin, J., Ji, F., & Yue, X. (2018). Carbon emission reduction and promotion policies considering social preferences and consumers’ low-carbon awareness in the cap-and-trade system. Journal of Cleaner Production,195, 1105–1124.

Yang, P. C., & Wee, H. M. (2002). A single-vendor and multiple-buyers production–inventory policy for a deteriorating item. European Journal of Operational Research,143(3), 570–581.

Yassine, N. (2016). Joint probability distribution and the minimum of a set of normalized random variables. Procedia - Social and Behavioral Sciences,230(12), 235–239.

Yassine, N., AlSagheer, A., & Azzam, N. (2018). A bundling strategy for items with different quality based on functions involving the minimum of two random variables. International Journal of Engineering Business Management,10, 1–9.

Zanoni, S., Mazzoldi, L., & Jaber, M. Y. (2014). Vendor-managed inventory with consignment stock agreement for single vendor–single buyer under the emission-trading scheme. International Journal of Production Research,52(1), 20–31.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yassine, N. A sustainable economic production model: effects of quality and emissions tax from transportation. Ann Oper Res 290, 73–94 (2020). https://doi.org/10.1007/s10479-018-3069-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-018-3069-7