Abstract

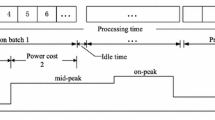

Time-of-use (TOU) electricity pricing policy is widely encountered in the world, which provides new opportunities for power-intensive enterprises to save their energy cost. A good trade-off between the total electricity cost and production efficiency is desired by decision makers. This work addresses an energy-conscious bi-objective single-machine batch scheduling problem under TOU electricity tariffs, in which electricity price varies with time. The objective of the problem is to simultaneously minimize total electricity cost and makespan. Due to its strong NP-hard nature, two fast new \(\epsilon \)-constraint-based constructive heuristic algorithms are developed to solve it. The core idea is to transform the bi-objective problem into a series of single-objective problems that are fast and heuristically solved to obtain an approximate Pareto front. Especially, for each transformed single-objective problem, two novel constructive heuristic algorithms are proposed by solving a series of multiple knapsack problems and 0–1 knapsack problems, respectively. Computational results on 145 benchmark and 80 newly generated larger-scale instances show that the proposed algorithms are quite efficient and are able to find high-quality Pareto solutions for large-scale problems with up to 200 batches.

Similar content being viewed by others

References

APEC APERC. (2013). APEC energy demand and supply outlook-5th edition. Technical report, Asia-Pacific Economic Cooperation.

Che, A., Feng, J., Chen, H., & Chu, C. (2015). Robust optimization for the cyclic hoist scheduling problem. European Journal of Operational Research, 240(3), 627–636.

Che, A., Zeng, Y., & Lyu, K. (2016). An efficient greedy insertion heuristic for energy-conscious single machine scheduling problem under time-of-use electricity tariffs. Journal of Cleaner Production, 129, 565–577.

Che, A., Zhang, S., & Wu, X. (2017). Energy-conscious unrelated parallel machine scheduling under time-of-use electricity tariffs. Journal of Cleaner Production, 156, 688–697.

Che, A., Zhang, Y., & Feng, J. (2017). Bi-objective optimization for multi-floor facility layout problem with fixed inner configuration and room adjacency constraints. Computers & Industrial Engineering, 105, 265–276.

Cheng, J., Chu, F., Chu, C., & Xia, W. (2016a). Bi-objective optimization of single-machine batch scheduling under time-of-use electricity prices. RAIRO-Operations Research, 50(4–5), 715–732.

Cheng, J., Chu, F., Liu, M., Wu, P., & Xia, W. (2017). Bi-criteria single-machine batch scheduling with machine on/off switching under time-of-use tariffs. Computers & Industrial Engineering, 112, 721–734.

Cheng, J., Chu, F., Ming, L., & Xia, W. (2016b). Single-machine batch scheduling under time-of-use tariffs: New mixed-integer programming approaches. In 2016 IEEE International Conference on Systems, Man, and Cybernetics, Budapest, Hungary (pp. 3498–3503). IEEE.

Cheng, J., Chu, F., Xia, W., Ding, J., & Ling, X. (2014). Bi-objective optimization for single-machine batch scheduling considering energy cost. In 2014 IEEE International Conference on Control, Decision and Information Technologies (CoDIT) (pp. 236–241). IEEE.

Cheng, J. H., Chu, F., & Zhou, M. C. (2018). An improved model for parallel machine scheduling under time-of-use electricity price. IEEE Transactions on Automation Science and Engineering, 15, 896–899.

Dahmani, I., & Hifi, M. (2019). A modified descent method-based heuristic for binary quadratic knapsack problems with conflict graphs. Annals of Operations Research,. https://doi.org/10.1007/s10479-019-03290-3.

Demir, E., Bektaş, T., & Laporte, G. (2014). The bi-objective pollution-routing problem. European Journal of Operational Research, 232(3), 464–478.

Ding, J. Y., Song, S., Zhang, R., Chiong, R., & Wu, C. (2016). Parallel machine scheduling under time-of-use electricity prices: New models and optimization approaches. IEEE Transactions on Automation Science and Engineering, 13, 1138–1154.

Fang, K., Uhan, N. A., Zhao, F., & Sutherland, J. W. (2016). Scheduling on a single machine under time-of-use electricity tariffs. Annals of Operations Research, 238(1–2), 199–227.

Fanti, M., Maione, B., Piscitelli, G., & Turchiano, B. (1996). Heuristic scheduling of jobs on a multi-product batch processing machine. International Journal of Production Research, 34(8), 2163–2186.

Haimes, Y. Y., Lasdon, L. S., & Wismer, D. A. (1971). On a bicriterion formulation of the problems of integrated system identification and system optimization. IEEE Transactions on Systems Man and Cybernetics, 0(1), 296–297.

Jia, Z. H., Li, K., & Leung, Y. T. (2015). Effective heuristic for makespan minimization in parallel batch machines with non-identical capacities. International Journal of Production Economics, 169, 1–10.

Ji, M., Yang, Q., Yao, D., & Cheng, T. C. E. (2015). Single-machine batch scheduling of linear deteriorating jobs. Theoretical Computer Science, 580, 36–49.

Lee, C. Y. (1999). Minimizing makespan on a single batch processing machine with dynamic job arrivals. International Journal of Production Research, 37(1), 219–236.

Lee, C. Y., Lei, L., & Pinedo, M. (1997). Current trends in deterministic scheduling. Annals of Operations Research, 70, 1–41.

Li, X., Li, Y., & Huang, Y. (2019). Heuristics and lower bound for minimizing maximum lateness on a batch processing machine with incompatible job families. Computers & Operations Research, 106, 91–101.

Lu, S. M., Lu, C., Tseng, K. T., Chen, F., & Chen, C. L. (2013). Energy-saving potential of the industrial sector of Taiwan. Renewable and Sustainable Energy Reviews, 21, 674–683.

Luo, H., Du, B., Huang, G. Q., Chen, H., & Li, X. (2013). Hybrid flow shop scheduling considering machine electricity consumption cost. International Journal of Production Economics, 146(2), 423–439.

Makarouni, I., Psarras, J., & Siskos, E. (2015). Interactive bicriterion decision support for a large scale industrial scheduling system. Annals of Operations Research, 227(1), 45–61.

Mathirajan, M., & Sivakumar, A. (2006). A literature review, classification and simple meta-analysis on scheduling of batch processors in semiconductor. The International Journal of Advanced Manufacturing Technology, 29(9–10), 990–1001.

Méndez, C. A., Cerdá, J., Grossmann, I. E., Harjunkoski, I., & Fahl, M. (2006). State-of-the-art review of optimization methods for short-term scheduling of batch processes. Computers & Chemical Engineering, 30(6), 913–946.

Miettinen, K. (1998). A posteriori methods. In Nonlinear Multiobjective Optimization. (pp. 77–113). Boston: Springer.

Mitra, S., Grossmann, I. E., Pinto, J. M., & Arora, N. (2012). Optimal production planning under time-sensitive electricity prices for continuous power-intensive processes. Computers & Chemical Engineering, 38, 171–184.

Mitra, S., Pinto, J. M., & Grossmann, I. E. (2014). Optimal multi-scale capacity planning for power-intensive continuous processes under time-sensitive electricity prices and demand uncertainty. Part I: Modeling. Computers & Chemical Engineering, 65, 89–101.

Moon, J. Y., Shin, K., & Park, J. (2013). Optimization of production scheduling with time-dependent and machine-dependent electricity cost for industrial energy efficiency. The International Journal of Advanced Manufacturing Technology, 68(1–4), 523–535.

Okabe, T., Jin, Y., & Sendhoff, B. (2003). A critical survey of performance indices for multi-objective optimisation. In The 2003 congress on evolutionary computation, CEC’03 (vol. 2, pp. 878–885). IEEE.

Penna, P. H. V., Subramanian, A., Ochi, L. S., Vidal, T., & Prins, C. (2019). A hybrid heuristic for a broad class of vehicle routing problems with heterogeneous fleet. Annals of Operations Research, 273(1–2), 5–74.

Pisinger, D. (1997). A minimal algorithm for the 0–1 knapsack problem. Operations Research, 45(5), 758–767.

Pisinger, D. (1999). An exact algorithm for large multiple knapsack problems. European Journal of Operational Research, 114(3), 528–541.

Potts, C. N., & Kovalyov, M. Y. (2000). Scheduling with batching: A review. European Journal of Operational Research, 120(2), 228–249.

Shrouf, F., Ordieres-Meré, J., García-Sánchez, A., & Ortega-Mier, M. (2014). Optimizing the production scheduling of a single machine to minimize total energy consumption costs. Journal of Cleaner Production, 67, 197–207.

Tan, M., Duan, B., & Su, Y. (2018). Economic batch sizing and scheduling on parallel machines under time-of-use electricity pricing. Operational Research, 18(1), 105–122.

Tang, L., & Huang, L. (2007). Optimal and near-optimal algorithms to rolling batch scheduling for seamless steel tube production. International Journal of Production Economics, 105(2), 357–371.

Uzsoy, R., Lee, C. Y., & Martin-Vega, L. A. (1992). A review of production planning and scheduling models in the semiconductor industry Part I: System characteristics, performance evaluation and production planning. IIE Transactions, 24(4), 47–60.

Uzsoy, R., Lee, C. Y., & Martin-Vega, L. A. (1994). A review of production planning and scheduling models in the semiconductor industry Part II: Shop-floor control. IIE Transactions, 26(5), 44–55.

Van De Rzee, D., Van Harten, A., & Schuur, P. (1997). Dynamic job assignment heuristics for multi-server batch operations-a cost based approach. International Journal of Production Research, 35(11), 3063–3094.

Wang, S., Liu, M., Chu, F., & Chu, C. (2016). Bi-objective optimization of a single machine batch scheduling problem with energy cost consideration. Journal of Cleaner Production, 137, 1205–1215.

Wang, S., Wang, X., Yu, J., Ma, S., & Liu, M. (2018). Bi-objective identical parallel machine scheduling to minimize total energy consumption and makespan. Journal of Cleaner Production, 193, 424–440.

Wang, S., Zhu, Z., Fang, K., Chu, F., & Chu, C. (2018). Scheduling on a two-machine permutation flow shop under time-of-use electricity tariffs. International Journal of Production Research, 56(9), 3173–3187.

Wang, Y., & Li, L. (2013). Time-of-use based electricity demand response for sustainable manufacturing systems. Energy, 63, 233–244.

Wu, P., Che, A., Chu, F., & Fang, Y. (2017). Exact and heuristic algorithms for rapid and station arrival-time guaranteed bus transportation via lane reservation. IEEE Transactions on Intelligent Transportation Systems, 18(8), 2028–2043.

Wu, P., Che, A., Chu, F., & Zhou, M. (2015). An improved exact \(\epsilon \)-constraint and cut-and-solve combined method for biobjective robust lane reservation. IEEE Transactions on Intelligent Transportation Systems, 16(3), 1479–1492.

www.chyxx.com. (2017). Development status and trend analysis of China’s semiconductor industry in 2017. http://www.chyxx.com/industry/201712/592628.html. Accessed July 19, 2019.

Xu, R., Chen, H., & Li, X. (2012). Makespan minimization on single batch-processing machine via ant colony optimization. Computers & Operations Research, 39(3), 582–593.

Yang, D. L., & Kuo, W. H. (2009). A single-machine scheduling problem with learning effects in intermittent batch production. Computers & Industrial Engineering, 57(3), 762–765.

Yin, Y., Cheng, T. C. E., Wu, C. C., & Cheng, S. R. (2014). Single-machine batch delivery scheduling and common due-date assignment with a rate-modifying activity. International Journal of Production Research, 52(19), 5583–5596.

Zeng, Y., Che, A., & Wu, X. (2018). Bi-objective scheduling on uniform parallel machines considering electricity cost. Engineering Optimization, 50(1), 19–36.

Zhang, H., Zhao, F., Fang, K., & Sutherland, J. W. (2014). Energy-conscious flow shop scheduling under time-of-use electricity tariffs. CIRP Annals-Manufacturing Technology, 63(1), 37–40.

Zhang, S., Che, A., Wu, X., & Chu, C. (2018). Improved mixed-integer linear programming model and heuristics for bi-objective single-machine batch scheduling with energy cost consideration. Engineering Optimization, 50(8), 1380–1394.

Zitzler, E. (1999). Evolutionary algorithms for multiobjective optimization: methods and applications. PhD thesis.

Zitzler, E., Thiele, L., Laumanns, M., Fonseca, C. M., & Da Fonseca, V. G. (2003). Performance assessment of multiobjective optimizers: An analysis and review. IEEE Transactions on Evolutionary Computation, 7(2), 117–132.

Acknowledgements

We acknowledge the support from the National Natural Science Foundation of China under Grants 71901069, 71701049 and 71571061, the Natural Science Foundation of Fujian Province, China under Grant 2018J05120, the Social Science Planning Foundation of Fujian Province under Grant FJ2017C013, in part by the Major Project Funding for Social Science Research Base in Fujian Province Social Science Planning under Grant FJ2018JDZ024, and in part by the fund of Key Laboratory of Intelligent Metro of Universities of Fujian Province under Grant 53001703.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Peng Wu and Junheng Cheng have contributed equally to this work.

Appendices

Appendix A

The notations used to formulate SMBS–TOU are defined as follows:

Indices and parameters:

- j::

-

Index of a job;

- J::

-

Set of jobs, \(j\in J\);

- |J|::

-

Number of jobs;

- \(p_j\)::

-

Processing time of job \(j, j\in J\);

- W::

-

Capacity of a batch;

- B::

-

Set of batches, \(B=\{1, 2,\ldots , |B|\}\);

- b::

-

Index of a batch, \(b \in B\);

- I::

-

Set of periods;

- |I|::

-

Number of periods;

- i::

-

Index of a period, \(i \in I\);

- \(D_i\)::

-

Duration of period \(i,~i\in I\);

- \(t_i\)::

-

Starting time of period \(i,~1 \le i \le |I|+1\);

- \(u_i\)::

-

Unit electricity cost of period \(i,~ i \in I\).

Decision variables:

- |B|::

-

Number of the formed batches;

- \(x_{jbi}\)::

-

\(x_{jbi}=1\) if job j is assigned to batch b and the batch is processed in period i; and \(x_{jbi}=0\) otherwise; \(\forall j\in J, b\in B, i\in I\);

- \(y_{bi}\)::

-

\(y_{bi}=1\) if batch \(b\in B\) is processed in period i; and \(y_{bi}=0\) otherwise; \(\forall b\in B, i\in I\);

- \(z_i\)::

-

\(z_i=1\) if at least one batch is processed in period i; and \(z_i=0\) otherwise; \(\forall i\in I\);

- \(P_{bi}\)::

-

\(P_{bi}=\max {p_j|j\in b}\), if batch \(b\in B\) is processed in period i; and \(P_{bi}=0\) otherwise; \(\forall b\in B, i\in I\);

- \({\textit{T}EC}\)::

-

Total electricity cost;

- \(C_{max}\)::

-

Makespan, i.e., maximum completion time.

With the notations defined above, the studied SMBS–TOU can be formulated as the following integer program (Cheng et al. 2014).

Model \({\mathcal {P}}_{0}:\)

The objective functions (29) and (30) are to minimize the total electricity cost TEC and the makespan, respectively. (31) ensures that a job is processed in a batch within a period. (32) denotes that a batch is processed within a period. The batch capacity constraint is imposed by (33). (34) defines the processing time of a batch. (35) denotes the total batch processing time in a period should not exceed its duration. (36) and (37) define the makespan and the total electricity cost, respectively. (38)–(43) impose the restrictions on decision variables. Note that the number of batches |B| can be initially considered as its upper bound |J| to obtain an integer linear model.

Appendix B

The LPT batching rule is illustrated by the following example. Consider a small-scale problem, there are five jobs with processing time 5, 4, 3, 2, and 1 that need to be processed, then with the LPT rule, three bathes with processing time 5, 3, and 1 can be formed in which the first batch involves the jobs of the first two longest processing time while the last one involves the job of the shortest processing time, which is shown in Fig. 5.

Rights and permissions

About this article

Cite this article

Wu, P., Cheng, J. & Chu, F. Large-scale energy-conscious bi-objective single-machine batch scheduling under time-of-use electricity tariffs via effective iterative heuristics. Ann Oper Res 296, 471–494 (2021). https://doi.org/10.1007/s10479-019-03494-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-019-03494-7