Abstract

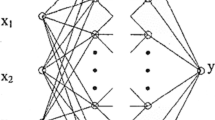

Hard turning with cubic boron nitride (CBN) tools has been proven to be more effective and efficient than traditional grinding operations in machining hardened steels. However, rapid tool wear is still one of the major hurdles affecting the wide implementation of hard turning in industry. Better prediction of the CBN tool wear progression helps to optimize cutting conditions and/or tool geometry to reduce tool wear, which further helps to make hard turning a viable technology. The objective of this study is to design a novel but simple neural network-based generalized optimal estimator for CBN tool wear prediction in hard turning. The proposed estimator is based on a fully forward connected neural network with cutting conditions and machining time as the inputs and tool flank wear as the output. Extended Kalman filter algorithm is utilized as the network training algorithm to speed up the learning convergence. Network neuron connection is optimized using a destructive optimization algorithm. Besides performance comparisons with the CBN tool wear measurements in hard turning, the proposed tool wear estimator is also evaluated against a multilayer perceptron neural network modeling approach and/or an analytical modeling approach, and it has been proven to be faster, more accurate, and more robust. Although this neural network-based estimator is designed for CBN tool wear modeling in this study, it is expected to be applicable to other tool wear modeling applications.

Similar content being viewed by others

References

Abrao A.M., Wise M.L.H., Aspinwall D.K. (1995). Tool life and workpiece surface integrity evaluations when machining hardened AISI 52,100 steels with conventional ceramic and PCBN tool materials. SME Technical Paper MR95-159, 1–9

Alessandri A. (2002). Optimization-based learning with bounded error for feedforward neural networks. IEEE Transactions on Neural Networks 13(2): 261–273

Bierman G. (1977). Factorization methods for discrete sequential estimation. New York, Academic Press

Boyd M., Kaastra I., Kermanshahi B., Kohzadi N. (1996). A comparison of artificial neural network and time series models for forecasting commodity prices. Neurocomputing 10, 169–181

Chryssoluouris G., Guillot M. (1990). A comparison of statistical and AI approaches to the selection of process parameters in intelligent machining. ASME Journal of Engineering for Industry 112, 122–131

Chungchoo C., Saini D. (2002). On-line tool wear estimation in CNC turning operations using fuzzy neural network model. International Journal of Machine Tools & Manufacture 42, 29–40

Danaher S., Datta S., Waddle I., Hackney P. (2004). Erosion modeling using Bayesian regulated artificial neural networks. Wear 256, 879–888

Das S., Chattopadhyay A.B., Murthy A.S.R. (1996). Force parameters for on-line tool wear estimation: A neural network approach. Neural Networks 9, 1639–1645

Dawson, T. (2002). Machining hardened steel with polycrystalline cubic boron nitride cutting tools. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA.

Dewes R.C., Aspinwall D.K. (1996). The use of high speed machining for the manufacture of hardened steel dies. Transactions of NAMRI 24, 21–26

Dimla D.E. Sr., Lister P.M., Leighton N.J. (1997). Neural network solutions to the tool condition monitoring problem in metal cutting—a critical review of methods. International Journal of Machine Tools & Manufacture 37, 1219–1241

Dimla D.E. Sr., Lister P.M. (2000). On-line metal cutting tool condition monitoring. II: Tool-state classification using multi-layer perceptron neural networks. International Journal of Machine Tools & Manufacture 40, 769–781

Elanayar S.V.T., Shin Y.C. (1999). Robust tool wear monitoring using radial basis function neural network. ASME Journal of Dynamic Systems, Measurement and Control 117, 459–467

Haber R.E., Alique A. (2003). Intelligent process supervision for predicting tool wear in machining processes. Mechatronics 13, 825–849

Haykin S. (1999). Neural networks: A comprehensive foundation (2nd ed.). Upper Saddle River, NJ, Prentice-Hall

Huang, Y. (2002). Predictive modeling of tool wear rate with application to CBN hard turning. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA.

Huang Y., Dawson T.G. (2005). Tool crater wear depth modeling in CBN hard turning. Wear 258(9): 1455–1461

Huang Y., Liang S.Y. (2004a). Modeling of CBN tool flank wear progression in finish hard turning. ASME Journal of Manufacturing Science and Engineering 126, 98–106

Huang Y., Liang S.Y. (2004b). Modeling of CBN tool crater wear in finish hard turning. Internation Journal of Advanced Manufacturing Technology 24(9–10): 632–639

Huang Y., Liang S.Y. (2004c). Effect of cutting conditions on tool performance in hard turning. Transactions of NAMRI/SME 32, 511–518

Huang Y., Chou Y.K., Liang S.Y. (2007). CBN tool wear in hard turning: A survey on research progresses. International Journal of Advanced Manufacturing Technology 35(5–6): 443–453

Kamarthi, S. V., Sankar, G. S., Cohen, P. H., & Kumara, S. R. T. (1991). On-line tool wear monitoring using a Kohonen’s feature map. In: Proceeding of the First Artificial Neural Networks in Engineering Conference, St. Louis, pp. 639–644.

König W., Hochschule T., Komanduri R., Tönshoff D.H.K. (1984). Machining of hard materials. Annals of CIRP 33(2): 417–427

Kramer B.M. (1986). Predicted wear resistances of binary carbide coatings. Journal of Vacuum Science & Technology A4(6): 2870–2873

KrishnaKumar K. (1993). Optimization of the neural net connectivity pattern using a backpropagation algorithm. Neurocomputing 5, 273–286

KrishnaKumar K., Nishta K. (1999). Robustness analysis of neural networks with an application to system identification. Journal of Guidance, Control, and Dynamics 22, 695–701

Kuo R.J., Cohen P.H. (1998). Intelligent tool wear estimation system through artificial neural networks and fuzzy modeling. Artificial Intelligence in Engineering 12, 229–242

Kuo R.J., Cohen P.H. (1999). Multi-sensor integration for on-line tool wear estimation through radial basis function networks and fuzzy neural network. Neural Networks 12, 355–370

Lary D.J., Mussa H.Y. (2004). Using an extended Kalman filter learning algorithm for feed-forward neural networks to describe tracer correlations. Atmospheric Chemistry and Physics Discussion 4, 3653–3667

Li S. (2001). Comparative analysis of backpropagation and extended Kalman filter in pattern and batch forms for training neural networks. Neural Networks, Proceedings IJCNN ’01. International Joint Conference 1, 144–149

Lin S.C., Ting C.J. (1995). Drill wear monitoring using neural networks. International Journal of Machine Tools & Manufacture 36(4): 465–475

Liu Q., Altintas Y. (1999). On-line monitoring of flank wear in turning with multilayered feed-forward neural network. International Journal of Machine Tools & Manufacture 39, 1945–1959

Monostori L. (1993). A step towards intelligent manufacturing: Modelling and monitoring of manufacturing processes through artificial neural networks. Annals of the CIRP 42(1): 485–488

Obikawa T., Shinozuka J. (2004). Monitoring of flank wear of coated tools in high speed machining with a neural network ART2. International Journal of Machine Tools & Manufacture 44, 1311–1318

Ozel T., Nadgir A. (2002). Prediction of flank wear by using back propagation neural network modeling when cutting hardened H-13 steel with chamfered and honed tools. International Journal of Machine Tools & Manufacture 42, 287–297

Ozel T., Karpat Y. (2005). Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. International Journal of Machine Tools & Manufacture 45, 467–479

Panda S.S., Singh A.K., Chakraborty D., Pal S.K. (2006). Drill wear monitoring using back propagation neural network. Journal of Materials Processing Technology 172, 283–290

Poulachon G., Moisan A., Jawahir I.S. (2001). Tool-wear mechanisms in hard turning with polycrystalline cubic boron nitride tools. Wear 250, 576–586

Puskorius G.V., Feldkamp L.A., (1994). Neurocontrol of nonlinear dynamical systems with Kalman filter trained recurrent networks. IEEE Transactions on Neural Networks 5, 279–297

Rangwala S., Donfeld D. (1990). Sensor integration using neural networks for intelligent tool condition monitoring. Journal of Engineering for Industry Transactions ASME 112, 219–228

Rumelhart D.E., McClelland J. L. (1986). The PDP research group, parallel distributed processing: Explorations in the microstructure of cognition. Cambridge, MA, MIT Press

Sarkar D. (1995). DILIP methods to speed up error back-propagation learning algorithm. ACM Computing Surveys 27(4): 519–542

Schalkoff R.J. (1997). Artificial neural networks. New York, McGraw-Hill Inc

Scheffer C., Kratz H., Heyns P.S., Klocke F. (2003). Development of a tool wear-monitoring system for hard turning. International Journal of Machine Tools & Manufacture 43, 973–985

Sick, B. (1998). Online tool wear monitoring in turning using time-delay neural networks. In: Proceedings of the 1998 International Conference on Acoustics, Speech, and Signal Processing, 1, Seattle, May, 1998, pp. 445–448.

Sick B. (2002). On-line and indirect tool wear monitoring in turning with artificial neural networks: A review of more than a decade of research. Mechanical Systems and Signal Processing 16, 487–546

Singhal, S., & Wu, L. (1989). Training feed forward networks with extended Kalman filter algorithm. Proceedings – ICASSP, IEEE International Conference on Acoustics, Speech and Signal Processing, Glasgow, Scotland, 1187–1190.

Sivarao, P. S. (2005). Expert system suitability in modeling and analysis of tool wear in drilling. Proceedings of 2005 International Conference on MEMS, NANO and Smart Systems, pp. 473–476.

Sun J., Rahman M., Wong Y.S., Hong G.S. (2004). Multiclassification of tool wear with support vector machine by manufacturing loss consideration. International Journal of Machine Tools & Manufacture 44, 1179–1187

Takatsu S., Shimoda H., Otani K. (1983). Effect of CBN content on the cutting performance of polycrystalline CBN tools. International Journal of Refractory Metals & Hard Materials 2(4): 175–178

Tönshoff H.K., Arendt C., Amor R. B. (2000). Cutting of hardened steel. Annals of CIRP 49(2): 547–566

Usui E., Shirakashi T., Kitagawa T. (1978). Analytical prediction of three dimensional cutting process, part 3: Cutting temperature and crater wear of carbide tool. Journal of Engineering for Industry 100, 236–243

Wang, Z., & Dornfeld, D. A. (1992). In-process monitoring using neural networks. Proceedings of the 1992 Japan—USA Symposium on Flexible Automation Part 1 (of 2), San Francisco, CA (13–15th July, 1992), pp. 263–270.

Werbos P.J. (1990). Back propagation through time: what is does and how to do it. Proceedings of the IEEE 78(10): 1550–1560

Xie L.J., Schmidt J., Schmidt C., Biesinger F. (2005). 2D FEM estimate of tool wear in turning operation. Wear 258, 1479– 1490

Yen Y.C., Söhner J., Lilly B., Altan T. (2004). Estimation of tool wear in orthogonal cutting using the finite element analysis. Journal of Materials Processing Technology 146, 82–91

Zhang L. (2005). Neural network-based market clearing price prediction and confidence interval estimation with an improved extended Kalman filter method. IEEE Transactions on Power Systems 20(1): 59–66

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Wang, W., Huang, Y. et al. Design of neural network-based estimator for tool wear modeling in hard turning. J Intell Manuf 19, 383–396 (2008). https://doi.org/10.1007/s10845-008-0090-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-008-0090-8