Abstract

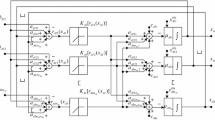

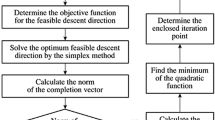

The traditional flatness control methods have the problems of limited control accuracy, slow responding and difficultly establishing a precise mathematical model, in addition, the traditional BP optimal algorithm exists the shortage of easy trapped in local minimum, flatness intelligent control based on GA–PIDNN was proposed. PIDNN controller does not rely on the mathematical model of controlled object and has excellent characteristics in the control system. Genetic algorithm (GA) has good parallel design structure and characteristics of global optimization. Flatness recognition model and flatness predictive model are established via GA–PIDNN by combining the merits of GA and PIDNN, on this basis, for the 900HC reversible cold rolling mill, the GA–PIDNN controller was designed to control the flatness defects effectively. Through the comparative study of PIDNN optimized by BP optimal algorithm, the simulation results show that this control method can quickly track flatness target value, improve flatness control accuracy, achieve good control result, and it is an effective flatness control method.

Similar content being viewed by others

References

Gabor, R., & Aniko, E. (2003). Genetic algorithms in computer aided design. Computer-Aided Design, 35, 709–726.

Jatinder, N. D. G., & Randall, S. S. (1999). Comparing backpropagation with a genetic algorithm for neural network training. The International Journal of Management Science, 27, 679–684.

Jia, C. Y., Shan, X. Y., & Liu, H. M. (2008). Fuzzy neural model for flatness pattern recognition. Journal of Iron and Steel Research, 15(6), 33–38.

Lei, Y. J., Zhang, S. W., Li, X. W., & Zhou, C. M. (2005). MATLAB genetic algorithm toolbox and application. Xi’an: Xian University of Electronic Science and Technology Press.

Li, L. J. (2008). The study of modeling and predictive control design based on least squares support vector machine. Hangzhou: Zhejiang University.

Lin, T. W., & Wang, C. H. (2012). A hybrid genetic algorithm to minimize the periodic preventive maintenance cost in a series-parallel system. Journal of Intelligent Manufacturing, 213, 1225–1236.

Liu, H. M., He, H. T., & Shan, X. Y. (2009). Flatness control based on dynamic effective matrix for cold strip mills. Chinese Journal of Mechanical Engineering, 22(2), 287–296.

Liu, H. M., Jia, C. Y., & Shan, X. Y. (2010). Application of intelligent methods in flatness control. Journal of Yanshan University, 34(1), 1–5.

Liu, J., Wang, Y. Q., & Sun, F. (2008). Fuzzy pattern recognition method of flatness based on particle swarm theory. Chinese Journal of Mechanical Engineering, 44(1), 173–178.

Sedighi, M., & Afshari, D. (2010). Creep feed grinding optimization by an integrated GA–NN system. Journal of Intelligent Manufacturing, 21, 657–663.

Shan, X. Y., Liu, H. M., & Jia, C. Y. (2010). A recognition method of new flatness pattern containing the cubic flatness. Iron and Steel, 45(8), 56–60.

Shu, H. L. (1999). Analysis of PID neural network multivariable control systems. Acta Automatica Sinica, 25(1), 105–110.

Shu, H. L. (2006). PID neural network and control system. Beijing: National Defense Industry Press.

Shu, H. L., & Pi, Y. G. (2000). PID neural networks for time-delay systems. Computers and Chemical Engineering, 24, 859–861.

Tseng, H. Y. (2006). A genetic algorithm for assessing flatness in automated manufacturing systems. Journal of Intelligent Manufacturing, 17, 301–306.

Zhang, X. L. (2002). Research on intelligent control and recognition of flatness for cold strip mill. Qinhuangdao: Yanshan University.

Zhang, X. L., & Liu, H. M. (2003). Ga–BP model of flatness pattern recognition and improved least-squares method. Iron and Steel, 38(10), 29–34.

Zhang, X. L., Pang, Z. P., & Li, S. Q. (2009). Flatness pattern recognition based on adaptive neuro-fuzzy inference system. Journal of Iron and Steel Research, 21(9), 59–62.

Zhang, X. L., Zhang, S. Y., Tan, G. Z., & Zhao, W. B. (2012). A novel method for flatness pattern recognition via least squares support vector regression. Journal of Iron and Steel Research, 19(3), 25–30.

Zhang, X. W., & Wang, Y. (2010). Application and development trend of intelligent recognition methods for flatness recognition. Journal of Iron and Steel Research, 22(1), 1–3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Xu, T., Zhao, L. et al. Research on flatness intelligent control via GA–PIDNN. J Intell Manuf 26, 359–367 (2015). https://doi.org/10.1007/s10845-013-0789-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0789-z