Abstract

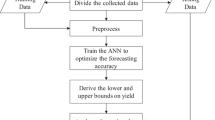

With the rapid change of manufacturing environments, semiconductor fabricators are forced to make continuous investments in advanced technology to maintain their competitive advantage. Wafer fabrication (fab) performance evaluations are important for examining past operations such as the capacity and resource allocation. In addition, forecasting provides useful information for what-if analyses to anticipate useful strategies early to avoid potential losses. However, the integration of performance evaluation and forecast based on a consideration of the relative performance along the time horizon has rarely been addressed. In particular, the part of performance evaluation is to generate the relative performance in a period with rolling data. Then, the forecast part is to build a model for performance prediction based on the result of present performance. This study aimed to construct a performance forecast model by integrating data envelopment analysis and a back-propagation neural network for performance evaluation and forecast, respectively. Empirical data from a leading semiconductor company in Taiwan was used to test the proposed model. The results provide basic information and early alarms to adjust the resource allocation before the future performance declines. The empirical analysis demonstrated the practical feasibility of the proposed approach.

Similar content being viewed by others

References

Berry, M., & Linoff, G. (2004). Data mining techniques for marketing, sales and customer support (2nd ed.). New York: Wiley.

Charnes, A., Clark, C. T., Cooper, W. W., & Golany, B. (1985). A developmental study of data envelopment analysis in measuring the efficiency of maintenance units in the U.S. air forces. Annals of Operation Research, 2(1), 95–112.

Charnes, A., Cooper, W. W., & Rhodes, E. (1978). Measuring the efficiency of decision making units. European Journal of Operational Research, 2(6), 429–444.

Chen, W.-C., & Chien, C.-F. (2011a). Measuring relative performance of wafer fabrication operation: A case study. Journal of Intelligent Manufacturing, 22(3), 447–457.

Chen, W.-C., & Chien, C.-F. (2011b). Evaluating capacity pooling strategy in semiconductor manufacturing: A productivity perspective study. International Journal of Production Research, 49(12), 3635–3652.

Chen, W.-C., & Cho, W.-J. (2009). A procedure for large-scale DEA computations. Computers & Operations Research, 36(6), 1813–1824.

Chen, W.-C., & Johnson, A.-L. (2010). A unified model for detecting efficient and inefficient outliers in data envelopment analysis. Computers & Operations Research, 37(2), 417–425.

Chien, C.-F., Chen, H.-K., Wu, J.-Z., & Hu, C.-H. (2007a). Constructing the OGE for promoting tool group productivity in semiconductor manufacturing. International Journal of Production Research, 45(3), 509–524.

Chien, C.-F., Chen, W.-C., & Hsu, S. (2010a). Requirement estimation for indirect workforce allocation in semiconductor manufacturing. International Journal of Production Research, 48(23), 6959–6976.

Chien, C.-F., Chen, W.-C., Lo, F.-Y., & Lin, Y.-C. (2007b). A case study to evaluate the productivity changes of the thermal power plants of the Taiwan power company. IEEE Transactions on Energy Conversion, 22(3), 680–688.

Chien, C.-F., Chen, Y.-J., & Peng, J.-T. (2010b). Manufacturing intelligence for semiconductor demand forecast based on technology diffusion and product life cycle. International Journal of Production Economics, 128(2), 496–509.

Chien, C.-F., Hsu, C.-Y., & Hsiao, C. (2012). Manufacturing intelligence to forecast and reduce semiconductor cycle time. Journal of Intelligent Manufacturing, 23(6), 2281–2294.

Chien, C.-F., Hsu, C.-Y., & Chang, K.-H. (2013). Overall wafer effectiveness (OWE): A novel industry standard for semiconductor ecosystem as a whole. Computers & Industrial Engineering, 65(1), 117–127.

Chien, C.-F., Lo, F.-Y., & Lin, J.-T. (2003). Using DEA to measure the relative efficiency of the service center and improve operation efficiency through reorganization. IEEE Transactions on Power Systems, 18(1), 366–373.

Chu, M. T., Shyu, J. Z., & Khosla, R. (2008). Measuring the relative performance for leading fabless firms by using data envelopment analysis. Journal of Intelligent Manufacturing, 19(3), 257–272.

Coelli, T. J., Rao, D. S. P., O’Donnell, C. J., & Battese, G. E. (2005). An introduction to efficiency and productivity analysis (2nd ed.). New York: Springer.

Cybenko, G. (1989). Approximation by superpositions of a sigmoidal function. Mathematics of Control, Signals and Systems, 2, 303–314.

Färe, R., & Primont, D. (1995). Multi-output production and duality: Theory and applications. Boston: Kluwer.

Farrell, M. J. (1957). The measurement of productive efficiency. Journal of the Royal Statistical Society, 120(3), 253–290.

Hornik, K. (1989). Multilayer feedforward networks are universal approximators. Neural Network, 2(5), 359–366.

Huang, C.-L., Huang, Y.-H., Chang, T.-Y., Chang, S.-H., Chung, C.-H., Huang, D.-T., et al. (1999). The construction of production performance prediction system for semiconductor manufacturing with artificial neural network. International Journal of Production Research, 37(6), 1387–1402.

Kao, C., & Hwang, S. N. (2008). Efficiency decomposition in two-stage data envelopment analysis: An application to non-life insurance companies in Taiwan. European Journal of Operational Research, 185(1), 418–429.

Khaw, J. F. C., Lim, B. S., & Lim, L. E. N. (1995). Optimal design of neural networks using the Taguchi method. Neurocomputing, 7(3), 225–245.

Kozmetsky, G., & Yue, P. (1998). Comparative performance of global semiconductor companies. Omega, 26(2), 153–175.

Kuo, Y., Yang, T., Peters, B. A., & Chang, I. (2007). Simulation metamodel development using uniform design and neural network for automated material handling systems in semiconductor wafer fabrication. Simulation Modelling Practice and Theory, 15(8), 1002–1015.

Kuo, C.-J., Chien, C.-F., & Chen, J. (2011). Manufacturing intelligence to exploit the value of production and tool data to reduce cycle time. IEEE Transaction on Automation Science Engineering, 8(1), 103–111.

LaValle, S. (2009). Business analytics and optimization for the intelligent enterprise. New York: IBM Global Business Services.

Leachman, R. C., & Hodges, D. A. (1996). Benchmarking semiconductor manufacturing. IEEE Transactions on Semiconductor Manufacturing, 9(2), 158–169.

Leachman, R. C., Ding, S., & Chien, C.-F. (2007). Economic efficiency analysis of wafer fabrication. IEEE Transactions on Automation Science and Engineering, 4(4), 501–512.

Lewis, C. D. (1982). Industrial and business forecasting method. London: Butterworth.

Lin, T.-H., Cheng, F.-T., Wu, W.-M., Kao, C.-A., Ye, A.-J., & Chang, F.-C. (2009). NN-based key-variable selection method for enhancing virtual metrology accuracy. IEEE Transactions on Semiconductor Manufacturing, 22(1), 204–211.

Liu, F.-H., & Wang, P-h. (2008). DEA Malmquist productivity measure: Taiwanese semiconductor companies. International Journal of Production Research, 112(1), 367–379.

Lo, F.-Y., Chien, C.-F., & Lin, J. T. (2001). A DEA study to evaluate the relative efficiency and investigate the district reorganization of the Taiwan power company. IEEE Transactions on Power Systems, 16(1), 170–178.

Patterson, D. (1996). Artificial neural networks: Theory and applications. Singapore: Prentice Hall.

Rietman, E. A., Patel, S. H., & Lory, E. R. (1996). Modeling and control of a semiconductor manufacturing process with an automata network: An example in plasma etch processing. Computers & Operation Research, 23(6), 573–585.

Rumelhart, D. E., Hinton, G. E., & Williams, R. J. (1986). Learning internal representation by error propagation. In L. M. James & D. E. Rumelhart (Eds.), Parallel distributed proceeding (Vol. 1, pp. 318–362). Cambridge: MIT Press.

SEMI E10-0701. (2000) Specification for definition and measurement of equipment reliability, availability, and maintainability (RAM). Mountain View, CA, USA: Semiconductor Equipment and Material International.

Shephard, R. W. (1970). Theory of costs and production functions. Princeton, NJ, USA: Princeton University Press.

Su, Y.-C., Lin, T.-H., Cheng, F.-T., & Wu, W.-M. (2008). Accuracy and real-time considerations for implementing various virtual metrology algorithms. IEEE Transactions on Semiconductor Manufacturing, 21(3), 426–434.

Acknowledgments

This research is supported by National Science Council, Taiwan (NSC 101-2221-E-155-035). The author appreciates the invaluable comments from anonymous reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, CY. Integrated data envelopment analysis and neural network model for forecasting performance of wafer fabrication operations. J Intell Manuf 25, 945–960 (2014). https://doi.org/10.1007/s10845-013-0808-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0808-0