Abstract

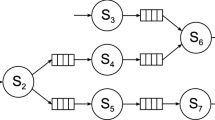

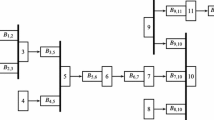

This paper presents a new approximate analytical method for the performance evaluation of inhomogeneous assembly/disassembly (A/D) systems with machines subject to failures and finite buffers. Processing times of machines in these systems are deterministic but not identical. Times between failures and times to repair are both assumed to be exponentially distributed. The method developed in this paper provides a generalized approach for analyzing A/D systems. Unlike the previous work on this subject, generalized exponential distributions are adopted instead of exponential distributions to approximate the repair time distributions of the fictitious machines. As a result the proposed method can handle the situation where the orders of magnitude of machines’ reliability parameters (mean times between failures and mean times to repair) are not at the same level. A new algorithm is also developed to improve the convergence reliability and efficiency of the method. Extensive numerical experiments and simulation have been carried out to illustrate that the method proposed for A/D systems is quite accurate and efficient.

Similar content being viewed by others

References

Bonvik, A. M. (1996). Performance analysis of manufacturing systems under hybrid control policies. Thesis (PhD), Massachusetts Institute of Technology.

Burman, M. H. (1995). New results in flow line analysis. Thesis (PhD), Massachusetts Institute of Technology.

Buzacott, J. A. (1967). Automatic transfer lines with buffer stocks. International Journal of Production Research, 5(3), 183–200.

Chen, Y.-S., Cheng, C.-H., & Lai, C.-J. (2010). A hybrid procedure for extracting rules of production performance in the automobile parts industry. Journal of Intelligent Manufacturing, 21(4), 423–437.

Choong, Y. F., & Gershwin, S. B. (1987). A decomposition method for the approximate evaluation of capacitated transfer lines with unreliable machines and random processing times. IIE Transactions, 19(2), 150–159.

Ciprut, P., Hongler, M.-O., & Salama, Y. (2000). Fluctuations of the production output of transfer lines. Journal of Intelligent Manufacturing, 11(2), 183–189.

Dallery, Y. (1994). On modeling failure and repair times in stochastic models of manufacturing systems using generalized exponential distributions. Queueing Systems, 15(1), 199–209.

Dallery, Y., & Gershwin, S. B. (1992). Manufacturing flow line systems: A review of models and analytical results. Queueing Systems, 12(1), 3–94.

Dallery, Y., & Le Bihan, H. (1999). An improved decomposition method for the analysis of production lines with unreliable machines and finite buffers. International Journal of Production Research, 37(5), 1093–1117.

Dallery, Y., David, R., & Xie, X. L. (1988). An efficient algorithm for analysis of transfer lines with unreliable machines and finite buffers. IIE Transactions, 20(3), 280–283.

Dallery, Y., David, R., & Xie, X. L. (1989). Approximate analysis of transfer lines with unreliable machines and finite buffers. IEEE Transactions on Automatic Control, 34(9), 943–953.

Demir, L., Tunali, S., & Eliiyi, D. T. (2012). The state of the art on buffer allocation problem: A comprehensive survey. Journal of Intelligent Manufacturing, 1–22.

Dolgui, A., Eremeev, A. V., & Sigaev, V. S. (2007). HBBA: Hybrid algorithm for buffer allocation in tandem production lines. Journal of Intelligent Manufacturing, 18(3), 411–420. doi:10.1007/s10845-007-0030-z.

Duenyas, I. (1994). Estimating the throughput of a cyclic assembly system. International Journal of Production Research, 32(6), 1403–1419.

Gershwin, S. B. (1987). An efficient decomposition method for the approximate evaluation of tandem queues with finite storage space and blocking. Operations Research, 35(2), 291–305.

Gershwin, S. B. (1991). Assembly/disassembly systems: An efficient decomposition algorithm for tree-structured networks. IIE Transactions, 23(4), 302–314.

Gershwin, S. B. (1994). Manufacturing systems engineering. Engelwood Cliffs, NJ: Prentice Hall.

Gershwin, S. B., & Burman, M. H. (2000). A decomposition method for analyzing inhomogeneous assembly/disassembly systems. Annals of Operations Research, 93(1–4), 91–115.

Gershwin, S. B., & Schick, I. C. (1980). Continuous model of an unreliable two-stage material flow system with a finite interstagebuffer. Cambridge, Massachusetts: Massachusetts Institute of Technology.

Gershwin, S. B., & Werner, L. M. (2007). An approximate analytical method for evaluating the performance of closed-loop flow systems with unreliable machines and finite buffers. International Journal of Production Research, 45(14), 3085–3111.

Glassey, C. R., & Hong, Y. (1993). Analysis of behaviour of an unreliable n-stage transfer line with (n\(-\)1) inter-stage storage buffers. International Journal of Production Research, 31(3), 519–530.

Helber, S. (1998). Decomposition of unreliable assembly/disassembly networks with limited buffer capacity and random processing times. European Journal of Operational Research, 109(1), 24–42.

Hillier, F. S., & Boling, R. W. (1967). Finite queues in series with exponential or Erlang service times-a numerical approach. Operations Research, 15(2), 286–303.

Hongler, M.-O. (1997). Analytical results for the performance and the control of stochastic flow systems. Journal of Intelligent Manufacturing, 8(5), 435–447.

Levantesi, R., Matta, A., & Tolio, T. (2003). Performance evaluation of continuous production lines with machines having different processing times and multiple failure modes. Performance Evaluation, 51(2–4), 247–268.

Le Bihan, H., & Dallery, Y. (2000). A robust decomposition method for the analysis of production lines with unreliable machines and finite buffers. Annals of Operations Research, 93(1), 265–297.

Li, J., Blumenfeld, D. E., Huang, N., & Alden, J. M. (2009). Throughput analysis of production systems: Recent advances and future topics. International Journal of Production Research, 47(14), 3823– 3851.

Mascolo, M. D., David, R., & Dallery, Y. (1991). Modeling and analysis of assembly systems with unreliable machines and finite buffers. IIE Transactions, 23(4), 315–330.

Massim, Y., Yalaoui, F., Chatelet, E., Yalaoui, A., & Zeblah, A. (2012). Efficient immune algorithm for optimal allocations in series-parallel continuous manufacturing systems. Journal of Intelligent Manufacturing, 23(5), 1603–1619.

Matta, A., Pezzoni, M., & Semeraro, Q. (2012). A Kriging-based algorithm to optimize production systems approximated by analytical models. Journal of Intelligent Manufacturing, 23(3), 587– 597.

Papadopoulos, H. T., & Heavey, C. (1996). Queueing theory in manufacturing systems analysis and design: A classification of models for production and transfer lines. European Journal of Operational Research, 92(1), 1–27.

Sevast’yanov, B. A. (1962). Influence of storage bin capacity on the average standstill time of a production line. Theory of Probability and its Applications, 7(4), 429.

Xia, B., Xi, L., & Zhou, B. (2012). An improved decomposition method for evaluating the performance of transfer lines with unreliable machines and finite buffers. International Journal of Production Research, 50(15), 4009–4024.

Zimmern, B. (1956). Ètudes de la propagation des arrêsts aléatoires dans les chaines de production. Revue de Statistique Appliquée, 4(1), 85–104.

Acknowledgments

The authors acknowledge the financial Support of the National Natural Science Foundation of China (No. 71071115, No. 51375290 and 51205242) and the Innovation Program of Shanghai Municipal Education Commission (No. 13YZ002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, B., Zhou, B., Chen, C. et al. A generalized-exponential decomposition method for the analysis of inhomogeneous assembly/disassembly systems with unreliable machines and finite buffers. J Intell Manuf 27, 765–779 (2016). https://doi.org/10.1007/s10845-014-0912-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0912-9