Abstract

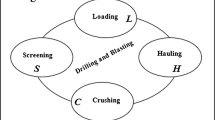

Blasting is one of the most important operations in mining projects involving production. Inappropriate blasting pattern may lead to unwanted events such as poor fragmentation, back break, fly rock, etc., as well as strong effects on the production rate. In fact, the selection of the most suitable pattern among the previously performed patterns can be considered as a Multi Attribute Decision Making problem. In this paper, first, from various performed patterns, the efficient and inefficient ones were determined using Data Envelopment Analysis. In the second step, linear assignment was used to evaluate the efficient patterns and recognize the most suitable pattern for providing high production rate. According to the obtained results, blasting pattern with the burden of 3.5 m, the spacing of 4.5 m, the stemming of 3.8 m and the hole length of 12.1 m was selected as the most appropriate blasting pattern and suggested for the future blasting operations.

Similar content being viewed by others

References

Ak, H., Iphar, M., Yavuz, M., & Konuk, A. (2009). Evaluation of ground vibration effect of blasting operations in a magnesite mine. Soil Dynamics and Earthquake Engineering, 29(4), 669–676.

Ak, H., & Konuk, A. (2008). The effect of discontinuity frequency on ground vibrations produced from bench blasting: A case study. Soil Dynamics and Earthquake Engineering, 28(9), 686–694.

Al-Refaie, A., & Al-Tahat, M. D. (2011). Solving the multi-response problem in Taguchi method by benevolent formulation in DEA. Journal of Intelligent Manufacturing, 22(4), 505–521.

Allen, R., & Thanassoulis, E. (2004). Improving envelopment in data envelopment analysis. European Journal of Operational Research, 154(2), 363–379.

Amini, H., Gholami, R., Monjezi, M., Torabi, S. R., & Zadhesh, J. (2011). Evaluation of flyrock phenomenon due to blasting operation by support vector machine. Neural Computing and Applications, 1–9.

Athanassopoulos, A. D., Lambroukos, N., & Seiford, L. (1999). Data envelopment scenario analysis for setting targets to electricity generating plants. European Journal of Operational Research, 115(3), 413–428.

Azadeh, A., Osanloo, M., & Ataei, M. (2010). A new approach to mining method selection based on modifying the Nicholas technique. Applied Soft Computing, 10(4), 1040–1061.

Bajpayee, T., Bhatt, S. K., Rehak, T. R., Engineer, G., Mowrey, G. L., & Ingram, D. K. (2003). Fatal accidents due to flyrock and lack of blast area security and working practices in mining. Journal of Mines, Metals and Fuels, 51(11–12), 344–349.

Bajpayee, T., Rehak, T., Mowrey, G., & Ingram, D. A. (2002). Summary of fatal accidents due to flyrock and lack of blast area security in surface mining, 1989 to 1999. In Proceedings of the annual of the conference on explosives and blasting technique, (Vol. 2, pp. 105–118): ISEE 1999.

Bajpayee, T., Rehak, T., Mowrey, G., & Ingram, D. (2004). Blasting injuries in surface mining with emphasis on flyrock and blast area security. Journal of Safety Research, 35(1), 47–57.

Bajpayee, T., Verakis, H., & Lobb, T. (2004). An analysis and prevention of flyrock accidents in surface blasting operations. In Proceedings of the annual of the conference on explosives and blasting technique, (Vol. 2, pp. 401–410): ISEE; 1999.

Bakhshandeh Amnieh, H., Siamaki, A., & Soltani, S. (2012). Design of blasting pattern in proportion to the peak particle velocity (PPV): Artificial neural networks approach. Safety Science, 50(9), 1913–1916.

Bal, H., Örkcü, H. H., & Çelebioğlu, S. (2010). Improving the discrimination power and weights dispersion in the data envelopment analysis. Computers and Operations Research, 37(1), 99–107.

Bazzazi, A. A., Osanloo, M., & Karimi, B. (2011). A new fuuzzy multi criteria decision making model for open pit mines equipment selection. Asia-Pacific Journal of Operational Research, 28(03), 279–300.

Bazzazi, A. A., Osanloo, M., & Soltanmohammadi, H. (2008). Loading-haulage equipment selection in open pit mines based on fuzzy-TOPSIS method. Gospodarka Surowcami Mineralnymi, 24.

Bejari, H., Shahriar, K., Hamidi, J. K., & Shirazi, M. A. (2010). Optimal tunneling method selection using fuzzy multiple attribute decision making technique. In ISRM International symposium-6th Asian rock mechanics symposium.

Chakraborty, A., Raina, A., Ramulu, M., Choudhury, P., Haldar, A., Sahu, P., et al. (2004). Parametric study to develop guidelines for blast fragmentation improvement in jointed and massive formations. Engineering Geology, 73(1), 105–116.

Cho, S. H., & Kaneko, K. (2004). Rock fragmentation control in blasting. Materials Transactions, 45(5), 1722–1730.

Chu, M.-T., Shyu, J. Z., & Khosla, R. (2008). Measuring the relative performance for leading fabless firms by using data envelopment analysis. Journal of Intelligent Manufacturing, 19(3), 257–272.

Cooper, W. W., Seiford, L. M., & Tone, K. (2005). Introduction to data envelopment analysis and its uses: With DEA-solver software and references.

Cooper, W. W., Seiford, L. M., & Tone, K. (2007). Data envelopment analysis: A comprehensive text with models, applications, references and DEA-solver software. Berlin: Springer.

Crum, S., & Crum, S. (1990). Fractal concepts applied to bench-blast fragmentation. Rock Mechanics Contributions and Challenges: Proc. 919.

Dağdeviren, M. (2008). Decision making in equipment selection: An integrated approach with AHP and PROMETHEE. Journal of Intelligent Manufacturing, 19(4), 397–406.

Dehghani, H., & Ataee-Pour, M. (2011). Development of a model to predict peak particle velocity in a blasting operation. International Journal of Rock Mechanics and Mining Sciences, 48(1), 51–58.

Erarslan, K., Uysal, Ö., Arpaz, E., & Cebi, M. A. (2008). Barrier holes and trench application to reduce blast induced vibration in Seyitomer coal mine. Environmental Geology, 54(6), 1325–1331.

Gate, W., Ortiz, B., & Florez, R. (2005). Analysis of rockfall and blasting backbreak problems. In Paper ARMA/USRMS, proceedings of the American rock mechanics conference, (Vol. 5, pp. 671–680).

Ghasemi, E., Amini, H., Ataei, M., & Khalokakaei, R. (2012a). Application of artificial intelligence techniques for predicting the flyrock distance caused by blasting operation. Arabian Journal of Geosciences, 1–10.

Ghasemi, E., Sari, M., & Ataei, M. (2012b). Development of an empirical model for predicting the effects of controllable blasting parameters on flyrock distance in surface mines. International Journal of Rock Mechanics and Mining Sciences, 52, 163–170.

Guoliang, Z., & Sijing, C. (2010). The application of fuzzy comprehensive evaluation and topsis approach to selection of optimum underground mining method. In information science and engineering (ICISE), 2010 2nd international conference on, 2010 (pp. 6233–6237): IEEE.

Guosheng, Z., Jiang, L., & Kui, Z. (2011). Structural safety criteria for blasting vibration based on wavelet packet energy spectra. Mining Science and Technology (China), 21(1), 35–40.

Hekmat, A., Osanloo, M., & Shirazi, A. (2008). New approach for selection of waste dump sites in open pit mines. Mining Technology, 117(1), 24–31.

Hermans, E., Brijs, T., Wets, G., & Vanhoof, K. (2009). Benchmarking road safety: Lessons to learn from a data envelopment analysis. Accident Analysis and Prevention, 41(1), 174–182.

Hudaverdi, T. (2012). Application of multivariate analysis for prediction of blast-induced ground vibrations. Soil Dynamics and Earthquake Engineering, 43, 300–308.

Hwang, C. L., & Yoon, K. (1981). Multiple attribute decision making: Methods and applications: A state-of-the-art survey (Vol. 13). New York: Springer-Verlag.

Inanloo Arabi Shad, H., & Ahangari, K. (2012). An empirical relation to calculate the proper burden in blast design of open pit mines based on modification of the Konya relation. International Journal of Rock Mechanics and Mining Sciences, 56, 121–126.

Iphar, M., Yavuz, M., & Ak, H. (2008). Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Environmental Geology, 56(1), 97–107.

Jimeno, C. (1995). Rock drilling and blasting. Rotterdam, Brookfield: AA Balkema.

Kao, C., & Liu, S.-T. (2009). Stochastic data envelopment analysis in measuring the efficiency of Taiwan commercial banks. European Journal of Operational Research, 196(1), 312–322.

Kecojevic, V., & Radomsky, M. (2005). Flyrock phenomena and area security in blasting-related accidents. Safety Science, 43(9), 739–750.

Khandelwal, M., & Monjezi, M. (2012). Prediction of backbreak in open-pit blasting operations using the machine learning method. Rock Mechanics and Rock Engineering, 1–8.

Kulatilake, P., Qiong, W., Hudaverdi, T., & Kuzu, C. (2010). Mean particle size prediction in rock blast fragmentation using neural networks. Engineering Geology, 114(3), 298–311.

Lashgari, A., Fouladgar, M. M., Yazdani-Chamzini, A., & Skibniewski, M. J. (2011). Using an integrated model for shaft sinking method selection. Journal of Civil Engineering and Management, 17(4), 569–580.

Lashgari, A., Yazdani-Chamzini, A., Fouladgar, M. M., Zavadskas, E. K., Shafiee, S., & Abbate, N. (2012). Equipment selection using fuzzy multi criteria decision making model: Key study of gole gohar iron min. Engineering Economics, 23(2), 125–136.

Lashgari, A., Yazdani, A., & Sayadi, A. (2010). Methods for equipments selection in surface mining; review.

Latham, J.-P., Van Meulen, J., & Dupray, S. (2006). Prediction of fragmentation and yield curves with reference to armourstone production. Engineering Geology, 87(1), 60–74.

Li, S., Jahanshahloo, G. R., & Khodabakhshi, M. (2007). A super-efficiency model for ranking efficient units in data envelopment analysis. Applied Mathematics and Computation, 184(2), 638–648.

Little, T., & Blair, D. (2010). Mechanistic Monte Carlo models for analysis of flyrock risk. Rock Fragmentation by Blasting, 641–647.

Michaux, S., & Djordjevic, N. (2005). Influence of explosive energy on the strength of the rock fragments and SAG mill throughput. Minerals Engineering, 18(4), 439–448.

Mikaeil, R., Naghadehi, M. Z., Ataei, M., & KhaloKakaie, R. (2009). A decision support system using fuzzy analytical hierarchy process (FAHP) and TOPSIS approaches for selection of the optimum underground mining method. Archives of Mining Sciences, 54(2), 341–368.

Monjezi, M., Ahmadi, M., Sheikhan, M., Bahrami, A., & Salimi, A. (2010a). Predicting blast-induced ground vibration using various types of neural networks. Soil Dynamics and Earthquake Engineering, 30(11), 1233–1236.

Monjezi, M., Amini Khoshalan, H., & Yazdian Varjani, A. (2011a). Optimization of open pit blast parameters using genetic algorithm. International Journal of Rock Mechanics and Mining Sciences, 48(5), 864–869.

Monjezi, M., Amini Khoshalan, H., & Yazdian Varjani, A. (2012). Prediction of flyrock and backbreak in open pit blasting operation: A neuro-genetic approach. Arabian Journal of Geosciences, 5(3), 441.

Monjezi, M., Bahrami, A., Varjani, A. Y., & Sayadi, A. R. (2011b). Prediction and controlling of flyrock in blasting operation using artificial neural network. Arabian Journal of Geosciences, 4(3), 421–425.

Monjezi, M., & Dehghani, H. (2008). Evaluation of effect of blasting pattern parameters on back break using neural networks. International Journal of Rock Mechanics and Mining Sciences, 45(8), 1446–1453.

Monjezi, M., Ghafurikalajahi, M., & Bahrami, A. (2011c). Prediction of blast-induced ground vibration using artificial neural networks. Tunnelling and Underground Space Technology, 26(1), 46–50.

Monjezi, M., & Rezaei, M. (2011). Developing a new fuzzy model to predict burden from rock geomechanical properties. Expert Systems with Applications, 38(8), 9266–9273.

Monjezi, M., Rezaei, M., & Yazdian, A. (2010b). Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Systems with Applications, 37(3), 2637–2643.

Morin, M. A., & Ficarazzo, F. (2006). Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz-Ram model. Computers and Geosciences, 32(3), 352–359.

Namin, F. S., Shahriar, K., Ataee-pour, M., & Dehghani, H. (2008). A new model for mining method selection of mineral deposit based on fuzzy decision making.

Ning, K. (1999). Prevention measures for controlling flyrock in engineering blasting [J]. Blasting.

Ozkahraman, H. (2006). Fragmentation assessment and design of blast pattern at Goltas Limestone Quarry, Turkey. International Journal of Rock Mechanics and Mining Sciences, 43(4), 628–633.

Rehak, T., Bajpayee, T., Mowrey, G., & Ingram, D. (2001). Flyrock issues in blasting. In proceedings of the annual conference on explosives and blasting technique, 2001 (Vol. 1, pp. 165–176): ISEE; 1999.

Rezaei, M., & Monjezi, M. (2011). Development of a fuzzy model to predict flyrock in surface mining. Safety Science, 49(2), 298–305.

Sanchidrián, J., Segarra, P., & López, L. (2006). A practical procedure for the measurement of fragmentation by blasting by image analysis. Rock Mechanics and Rock Engineering, 39(4), 359–382.

Sheikhalishahi, M., Ebrahimipour, V., & Farahani, M. H. (2013). An integrated GA-DEA algorithm for determining the most effective maintenance policy for ak-out-of-n problem. Journal of Intelligent Manufacturing, 1–8.

Shim, H.-J., Ryu, D.-W., Chung, S.-K., Synn, J.-H., & Song, J.-J. (2009). Optimized blasting design for large-scale quarrying based on a 3-D spatial distribution of rock factor. International Journal of Rock Mechanics and Mining Sciences, 46(2), 326–332.

Shuran, L., & Shujin, L. (2011). Applying BP Neural Network Model to Forecast Peak Velocity of Blasting Ground Vibration. Procedia Engineering, 26, 257–263.

Singh, T., & Singh, V. (2005). An intelligent approach to prediction and control ground vibration in mines. Geotechnical and Geological Engineering, 23(3), 249–262.

Sowlati, T., Paradi, J. C., & Suld, C. (2005). Information systems project prioritization using data envelopment analysis. Mathematical and Computer Modelling, 41(11), 1279–1298.

Stojadinović, S., Pantović, R., & Žikić, M. (2011). Prediction of flyrock trajectories for forensic applications using ballistic flight equations. International Journal of Rock Mechanics and Mining Sciences, 48(7), 1086–1094.

Tota, E. W., Mudge, K., Branson, J. W., Georgiou, P. N., Gavrilovic, M., & Watson, J. D. (2001). Method and apparatus for flyrock control in small charge blasting. Google Patents.

Wang, C.-H., & Wu, H.-S. (2014). A novel framework to evaluate programmable logic controllers: A fuzzy MCDM perspective. Journal of Intelligent Manufacturing, 1–10.

Yazdani-Chamzini, A., & Yakhchali, S. H. (2012). Handling equipment selection in open pit mines by using an integrated model based on group decision making. International Journal of Industrial Engineering, 3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yari, M., Bagherpour, R. & Jamali, S. Development of an evaluation system for blasting patterns to provide efficient production. J Intell Manuf 28, 975–984 (2017). https://doi.org/10.1007/s10845-015-1036-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1036-6