Abstract

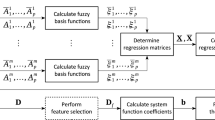

Accurate control chart patterns recognition (CCPR) plays an essential role in the implementation of control charts. However, it is a challenging problem since nonrandom control chart patterns (CCPs) are normally distorted by “common process variations”. In this paper, a novel method of CCPR by integrating fuzzy support vector machine (SVM) with hybrid kernel function and genetic algorithm (GA) is proposed. Firstly, two shape features and two statistical features that do not depend on the distribution parameters and number of samples are presented to explicitly describe the characteristics of CCPs. Then, a novel multiclass method based on fuzzy SVM with a hybrid kernel function is proposed. In this method, the influence of outliers on classification accuracy of SVM-based classifiers is weakened by assigning a degree of membership for every training sample. Meanwhile, a hybrid kernel function combining Gaussian kernel and polynomial kernel is adopted to further enhance the generalization ability of the classifiers. To solve the issue of features selection and parameters optimization, GA is used to simultaneously optimize the input features subsets and parameters of fuzzy SVM-based classifier. Finally, several simulation experiments and a real example are addressed to validate the feasibility and effectiveness of the proposed methodology. And the results of simulation experiments demonstrate that it can achieve excellent performance for CCPR and outperforms other approaches, such as learning vector quantization network, multi-layer perceptron network, probability neural network, fuzzy clustering and SVM, in term of recognition accuracy. The results of the practical cases manifest that the proposed method has application potential for solving the problem of control chart interpretation in real-world.

Similar content being viewed by others

References

Adankon, M. M., & Cheriet, M. (2009). Model selection for the LS-SVM. Application to handwriting recognition. Pattern Recognition, 42(12), 3264–3270.

Ahmadzadeh, F., Lundberg, J., & Stromberg, T. (2013). Multivariate process parameter change identification by neural network. International Journal of Advanced Manufacturing Technology, 69(9–12), 2261–2268.

Ahmed, I., Sultana, I., Paul, S. K., & Azeem, A. (2014). Performance evaluation of control chart for multiple assignable causes using genetic algorithm. International Journal of Advanced Manufacturing Technology, 70(9–12), 1889–1902.

Al-Assaf, Y. (2004). Recognition of control chart patterns using multi-resolution wavelets analysis and neural networks. Computers and Industrial Engineering, 47(1), 17–29. doi:10.1016/j.cie.2004.02.007.

Al-Ghanim, A. M., & Kamat, S. J. (1995). Unnatural pattern recognition on control charts using correlation analysis techniques. Computers and Industrial Engineering, 29(1), 43–47.

Al-Ghanim, A. M., & Ludeman, L. C. (1997). Automated unnatural pattern recognition on control charts using correlation analysis techniques. Computers and Industrial Engineering, 32(3), 679–690.

Assaleh, K., & Al-assaf, Y. (2005). Features extraction and analysis for classifying causable patterns in control charts. Computers and Industrial Engineering, 49(1), 168–181. doi:10.1016/j.cie.2005.01.021.

Bag, M., Gauri, S. K., & Chakraborty, S. (2012). An expert system for control chart pattern recognition. International Journal of Advanced Manufacturing Technology, 62(1–4), 291–301. doi:10.1007/s00170-011-3799-z.

Bahlmann, C., Haasdonk, B., & Burkhardt, H. (2002). Online handwriting recognition with support vector machines: A kernel approach. In 2002–01-01 (49–54: IEEE).

Bredensteiner, E. J., & Bennett, K. P. (1999). Multicategory classification by support vector machines computational optimization (pp. 53–79). New York: Springer.

Chen, Z., Lu, S., & Lam, S. (2007). A hybrid system for SPC concurrent pattern recognition. Advanced Engineering Informatics, 21(3), 303–310. doi:10.1016/j.aei.2007.03.002.

Cheng, C. S. (1997). A neural network approach for the analysis of control chart patterns. International Journal of Production Research, 35(3), 667–697. doi:10.1080/002075497195650.

Cheng, C., & Hubele, N. F. (1992). Design of a knowledge-based expert system for statistical process control. Computers and Industrial Engineering, 22(4), 501–517. doi:10.1016/0360-8352(92)90025-F.

Cheng, Z., & Ma, Y. (2008). A research about pattern recognition of control chart using probability neural network. In 2008–01-01 (2, pp. 140–145: IEEE)

Cortes, C., & Vapnik, V. (1995). Support vector network. Machine Learning, 20, 273–297.

Cristianini, N., & Shawe-Taylor, J. (2000). An introduction to support vector machines and other kernel-based learning methods. Cambridge: Cambridge University Press.

Du, S., Huang, D., & Lv, J. (2013). Recognition of concurrent control chart patterns using wavelet transform decomposition and multiclass support vector machines. Computers and Industrial Engineering, 66(4), 683–695. doi:10.1016/j.cie.2013.09.012.

Du, S., Yu, L. X. J., & Sun, J. (2010). Online intelligent monitoring and diagnosis of aircraft horizontal stabilizer assemble processes. International Journal Of Advanced Manufacturing Technology, 50, 377–389. doi:10.1007/s00170-009-2490-0.

Du, S., & Lv, J. (2013). Minimal Euclidean distance chart based on support vector regression for monitoring mean shifts of auto-correlated processes. International Journal of Production Economics, 141(1), 377–387. doi:10.1016/j.ijpe.2012.09.002.

Ducan, A. J. (1986). Quality control and industrial statistics (5th ed.). Homewood, IL: Richard D. Irwin.

Ebrahimzadeh, A., Addeh, J., & Rahmani, Z. (2012). Control chart pattern recognition using K-MICA clustering and neural networks. Isa Transactions, 51(1), 111–119. doi:10.1016/j.isatra.2011.08.005.

Ebrahimzadeh, A., & Ranaee, V. (2010). Control chart pattern recognition using an optimized neural network and efficient features. Isa Transactions, 49(3), 387–393. doi:10.1016/j.isatra.2010.03.007.

Ganapathiraju, A., Hamaker, J. E., & Picone, J. (2004). Applications of support vector machines to speech recognition. IEEE Transactions on Signal Processing, 52(8), 2348–2355.

Gauri, S. K. (2010). Control chart pattern recognition using feature-based learning vector quantization. International Journal of Advanced Manufacturing Technology, 48(9–12), 1061–1073. doi:10.1007/s00170-009-2354-7.

Gauri, S. K., & Chakraborty, S. (2006). Feature-based recognition of control chart patterns. Computers and Industrial Engineering, 51(4), 726–742. doi:10.1016/j.cie.2006.07.013.

Gauri, S. K., & Chakraborty, S. (2007). A study on the various features for effective control chart pattern recognition. International Journal of Advanced Manufacturing Technology, 34(3–4), 385–398. doi:10.1007/s00170-006-0591-6.

Ghiasabadi, A., Noorossana, R., & Saghaei, A. (2013). Identifying change point of a non-random pattern on (X)over-bar control chart using artificial neural networks. International Journal of Advanced Manufacturing Technology, 67(5–8), 1623–1630.

Gu, N., Cao, Z., Xie, L., Creighton, D., Tan, M., & Nahavandi, S. (2013). Identification of concurrent control chart patterns with singular spectrum analysis and learning vector quantization. Journal of Intelligent Manufacturing, 24(6), 1241–1252. doi:10.1007/s10845-012-0659-0.

Guh, R. S. (2008). Real-time recognition of control chart patterns in autocorrelated processes using a learning vector quantization network-based approach. International Journal of Production Research, 46(14), 3959–3991. doi:10.1080/00207540601011501.

Guh, R. S., & Tannock, J. (1999). A neural network approach to characterize pattern parameters in process control charts. Journal of Intelligent Manufacturing, 10(5), 449–462.

Guh, R. (2005). A hybrid learning-based model for on-line detection and analysis of control chart patterns. Computers and Industrial Engineering, 49(1), 35–62. doi:10.1016/j.cie.2005.03.002.

Gunn, S. R. (1998). Support vector machines for classification and regression. ISIS technical report, 14.

Hassan, A., Baksh, M., Shaharoun, A. M., & Jamaluddin, H. (2003). Improved SPC chart pattern recognition using statistical features. International Journal of Production Research, 41(7), 1587– 1603.

He, S., He, Z., & Wang, G. A. (2013). Online monitoring and fault identification of mean shifts in bivariate processes using decision tree learning techniques. Journal of Intelligent Manufacturing, 24(1), 25–34. doi:10.1007/s10845-011-0533-5.

Hsu, C., & Lin, C. (2002). A comparison of methods for multiclass support vector machines. IEEE Transactions on Neural Networks, 13(2), 415–425.

Kao, L., Lee, T., & Lu, C. (2014). A multi-stage control chart pattern recognition scheme based on independent component analysis and support vector machine. Journal Of Intelligent Manufacturing. doi:10.1007/s10845-014-0903-x.

Kuo, T., & Mital, A. (1993). Quality control expert systems: A review of pertinent literature. Journal of Intelligent Manufacturing, 4(4), 245–257.

Kwok, J. T. (2000). Automated Text Categorization Using Support Vector Machine. In Proceedings of the International Conference on Neural Information Processing (ICONIP).

Lin, S., Guh, R., & Shiue, Y. (2011). Effective recognition of control chart patterns in autocorrelated data using a support vector machine based approach. Computers and Industrial Engineering, 61(4), 1123–1134. doi:10.1016/j.cie.2011.06.025.

Masood, I., & Hassan, A. (2013). Pattern recognition for bivariate process mean shifts using feature-based artificial neural network. International Journal of Advanced Manufacturing Technology, 66(9–12), 1201–1218.

Michalewicz, Z., Janikow, C. Z., & Krawczyk, J. B. (1992). A modified genetic algorithm for optimal control problems. Computers and Mathematics With Applications, 23(12), 83–94. doi:10.1016/0898-1221(92)90094-X.

Montgomery, D. C. (2007). Introduction to statistical quality control. London: Wiley.

Nelson, L. S. (1984). The Shewhart control chart: Tests for special causes. Journal Of Quality Technology, 16(4), 237–239.

Pham, D. T., & Oztemel, E. (1994). Control chart pattern recognition using learning vector quantization networks. International Journal of Production Research, 32(3), 721–729.

Pham, D. T., & Wani, M. A. (1997). Feature-based control chart pattern recognition. International Journal of Production Research, 35(7), 1875–1890. doi:10.1080/002075497194967.

Pingyu, J., Daoyu, L., & Zhijian, Z. (2009). Recognizing control chart patterns with neural network and numerical fitting. Journal of Intelligent Manufacturing, 20(6), 625–635.

Ranaee, V., Ebrahimzadeh, A., & Ghaderi, R. (2010). Application of the PSO-SVM model for recognition of control chart patterns. Isa Transactions, 49(4), 577–586. doi:10.1016/j.isatra.2010.06.005.

Ranaee, V., & Ebrahimzadeh, A. (2011). Control chart pattern recognition using a novel hybrid intelligent method. Applied Soft Computing, 11(2), 2676–2686. doi:10.1016/j.asoc.2010.10.016.

Ranaee, V., & Ebrahimzadeh, A. (2013). Control chart pattern recognition using neural networks and efficient features: A comparative study. Pattern Analysis and Applications, 16(3), 321–332.

Swift, J. A. (1987). Development of a knowledge-based expert system for control-chart pattern recognition and analysis. Stillwater, OK, USA: Oklahoma State Univ.

Swift, J. A., & Mize, J. H. (1995a). Out-of-control pattern recognition and analysis for quality control charts using LISP-based systems. Computers and Industrial Engineering, 28(1), 81–91. doi:10.1016/0360-8352(94)00028-L.

Swift, J. A., & Mize, J. H. (1995b). Out-of-control pattern recognition and analysis for quality control charts using LISP-based systems. Computers and Industrial Engineering, 28(1), 81–91.

Takeyasu, K., & Kainosho, M. (2014). Optimization technique by genetic algorithms for international logistics. Journal of Intelligent Manufacturing, 25(5SI), 1043–1049.

Tan, Y., & Wang, J. (2004). A support vector machine with a hybrid kernel and minimal Vapnik–Chervonenkis dimension. IEEE Transactions on Knowledge and Data Engineering, 16(4), 385–395.

Vapnik, V. (2000). The nature of statistical learning theory. Berlin: springer.

Ventura, J. A., & Yoon, S. (2013). A new genetic algorithm for lot-streaming flow shop scheduling with limited capacity buffers. Journal of Intelligent Manufacturing, 24(6), 1185–1196. doi:10.1007/s10845-012-0650-9.

Wang, C., & Kuo, W. (2007). Identification of control chart patterns using wavelet filtering and robust fuzzy clustering. Journal of Intelligent Manufacturing, 18(3), 343–350. doi:10.1007/s10845-007-0028-6.

Wang, C., & Lin, S. (2002). Fuzzy support vector machines. Ieee Transactions on Neural Networks, 13(2), 464–471. doi:10.1109/72.991432.

Wani, M. A., & Rashid, S. (2005). Parallel algorithm for control chart pattern recognition. Paper presented at the Proceedings of the Fourth International Conference on Machine Learning and Applications (ICMLA2005).

Whitley, D. (1994). A genetic algorithm tutorial. Statistics and Computing, 4(2), 65–85. doi:10.1007/BF00175354.

Western Electric Company (1958). Statistical quality control handbook. Indianapolis: Western Electric Co., Inc.

Widodo, A., & Yang, B. (2007). Support vector machine in machine condition monitoring and fault diagnosis. Mechanical Systems and Signal Processing, 21(6), 2560–2574. doi:10.1016/j.ymssp.2006.12.007.

Xanthopoulos, P., & Razzaghi, T. (2014). A weighted support vector machine method for control chart pattern recognition. Computers and Industrial Engineering, 70(1), 134–149. doi:10.1016/j.cie.2014.01.014.

Yang, W., & Zhou, W. (2013). Autoregressive coefficient-invariant control chart pattern recognition in autocorrelated manufacturing processes using neural network ensemble, pp. 1–20. doi:10.1007/s10845-013-0847-6.

Acknowledgments

The research outcome is supported by the National Basic Research Program of China (973 program) with Grant No. 2011CB706805. The authors hereby thank the MOST of China for the financial aids.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, X., Jiang, P. & Wang, X. Recognition of control chart patterns using fuzzy SVM with a hybrid kernel function. J Intell Manuf 29, 51–67 (2018). https://doi.org/10.1007/s10845-015-1089-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1089-6