Abstract

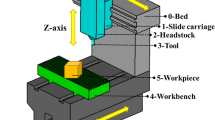

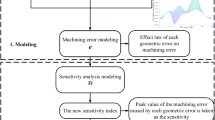

Although machine tool can meet the specifications while it is new, after a long period of cutting operations, the abrasion of contact surfaces and deformation of structures will degrade the accuracy of machine tool due to the increase of the geometric errors in six freedoms. Therefore, how to maintain its accuracy for quality control of products is of crucial importance to machine tool. In this paper, machining accuracy reliability is defined as the ability to perform its specified machining accuracy under the stated conditions for a given period of time, and a new method to analyze the sensitivity of geometric errors to the machining accuracy reliability is proposed. By applying Multi-body system theory, a comprehensive volumetric model explains how individual geometric errors affect the machining accuracy (the coupling relationship) was established. Based on Monte Carlo mathematic simulation method, the models of the machining accuracy reliability and sensitivity analysis of machine tools were developed. By taking the machining accuracy reliability as a measure of the ability of machine tool and reliability sensitivity as a reference of optimizing the basic parameters of machine tools, an illustrative example of a three-axis machine tool was selected to demonstrate the effectiveness of the proposed method.

Similar content being viewed by others

References

Ahn, K. G., & Cho, D. W. (2000). An analysis of the volumetric error uncertainty of a three-axis machine tool by beta distribution. International Journal of Machine Tools and Manufacture, 40(15), 2235–2248. doi:10.1016/S0890-6955(00)00048-1.

Andolfatto, L., Mayer, J., & Lavernhe, S. (2011). Adaptive Monte Carlo applied to uncertainty estimation in five axis machine tool link errors identification with thermal disturbance. International Journal of Machine Tools and Manufacture, 51(7), 618–627.

Avontuur, G. C., & van der Werff, K. (2002). Systems reliability analysis of mechanical and hydraulic drive systems. Reliability Engineering & System Safety, 77(2), 121–130.

Benkedjouh, T., Medjaher, K., Zerhouni, N., & Rechak, S. (2015). Health assessment and life prediction of cutting tools based on support vector regression. Journal of Intelligent Manufacturing, 26(2), 213–223. doi:10.1007/s10845-013-0774-6.

Bohez, E., Makhanov, S. S., & Sonthipermpoon, K. (2000). Adaptive nonlinear tool path optimization for five-axis machining. International Journal of Production Research, 38(17), 4329–4343.

Bohez, E. L. (2002a). Compensating for systematic errors in 5-axis NC machining. computer-aided design, 34(5), 391–403.

Bohez, E. L. (2002b). Five-axis milling machine tool kinematic chain design and analysis. International Journal of Machine Tools and Manufacture, 42(4), 505–520.

Bohez, E. L., Ariyajunya, B., Sinlapeecheewa, C., Shein, T. M. M., & Belforte, G. (2007). Systematic geometric rigid body error identification of 5-axis milling machines. Computer-aided Design, 39(4), 229–244.

Bohez, E. L., Minh, N. T. H., Kiatsrithanakorn, B., Natasukon, P., Ruei-Yun, H., & Son, L. T. (2003). The stencil buffer sweep plane algorithm for 5-axis CNC tool path verification. computer-aided design, 35(12), 1129–1142.

Bohez, E. L., Senadhera, S. R., Pole, K., Duflou, J. R., & Tar, T. (1997). A geometric modeling and five-axis machining algorithm for centrifugal impellers. Journal of Manufacturing Systems, 16(6), 422–436.

Cai, L., Zhang, Z., Cheng, Q., Liu, Z., & Gu, P. (2015). A geometric accuracy design method of multi-axis NC machine tool for improving machining accuracy reliability. Eksploatacja i Niezawodnosc: Maintenance and Reliability, 17(1), 143–155.

Çaydaş, U., & Ekici, S. (2012). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing, 23(3), 639–650.

Chen, B., Chen, X., Li, B., He, Z., Cao, H., & Cai, G. (2011). Reliability estimation for cutting tools based on logistic regression model using vibration signals. Mechanical Systems and Signal Processing, 25(7), 2526–2537.

Chen, G., Liang, Y., Sun, Y., Chen, W., & Wang, B. (2013). Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. The International Journal of Advanced Manufacturing Technology, 68(9–12), 2525–2534. doi:10.1007/s00170-013-4874-4.

Chen, J., Lin, S., & He, B. (2014). Geometric error compensation for multi-axis CNC machines based on differential transformation. The International Journal of Advanced Manufacturing Technology, 71(1–4), 635–642. doi:10.1007/s00170-013-5487-7.

Cheng, Q., Zhao, H., Zhang, G., Gu, P., & Cai, L. (2014). An analytical approach for crucial geometric errors identification of multi-axis machine tool based on global sensitivity analysis. The International Journal of Advanced Manufacturing Technology, 75(1–4), 107–121. doi:10.1007/s00170-014-6133-8.

De-Lataliade, A., Blanco, S., & Clergent, Y. (2007). Monte Carlo method and sensitivity estimations. Journal of Quantitative Spectroscopy and Radiative Transfer, 75(5), 529–538.

Deja, M., & Siemiatkowski, M. S. (2013). Feature-based generation of machining process plans for optimised parts manufacture. Journal of Intelligent Manufacturing, 24(4), 831–846.

Ditlevsen, O., & Ditlevsen, O. (1979). Narrow Reliability Bounds for Structural Systems. Journal of Structural Mechanics, 7(4), 453–472.

Ditlevsen, O., Madsen, H. (2007). Structural reliability methods. Chichester UK.

Dorndorf, U., Kiridena, V. S. B., & Ferreira, P. M. (1994). Optimal budgeting of quasistatic machine tool errors. Journal of Manufacturing Science and Engineering, 116(1), 42–53. doi:10.1115/1.2901808.

Du, X., Sudjianto, A., & Huang, B. (2005). Reliability-based design with the mixture of random and interval variables. Journal of Mechanical Design, 127(6), 1068–1076. doi:10.1115/1.1992510.

El Ouafi, A., Guillot, M., & Bedrouni, A. (2000). Accuracy enhancement of multi-axis CNC machines through on-line neurocompensation. Journal of Intelligent Manufacturing, 11(6), 535– 545.

Eman, K. F., Wu, B. T., & DeVries, M. F. (1987). A generalized geometric error model for multi-axis machines. CIRP Annals: Manufacturing Technology, 36(1), 253–256. doi:10.1016/S0007-8506(07)62598-0.

Fan, K.-C., Chen, H.-M., & Kuo, T.-H. (2012). Prediction of machining accuracy degradation of machine tools. Precision Engineering, 36(2), 288–298. doi:10.1016/j.precisioneng.2011.11.002.

Fleischer, J., Wawerla, M., & Niggeschmidt, S. (2007). Machine life cycle cost estimation via Monte-Carlo simulation. In Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses (pp. 449–453). Berlin: Springer.

Fu, G., Fu, J., Xu, Y., & Chen, Z. (2014). Product of exponential model for geometric error integration of multi-axis machine tools. The International Journal of Advanced Manufacturing Technology, 71(9–12), 1653–1667. doi:10.1007/s00170-013-5586-5.

Ghosh, R., Chakraborty, S., & Bhattacharyya, B. (2001). Stochastic sensitivity analysis of structures using first-order perturbation. Meccanica, 36(3), 291–296. doi:10.1023/A:1013951114519.

Guo, J., & Du, X. (2009). Reliability sensitivity analysis with random and interval variables. International Journal for Numerical Methods in Engineering, 78(13), 1585–1617.

Habibi, M., Arezoo, B., & Nojedeh, M. V. (2011). Tool deflection and geometrical error compensation by tool path modification. International Journal of Machine Tools and Manufacture, 51(6), 439–449. doi:10.1016/j.ijmachtools.2011.01.009.

Homma, T., & Saltelli, A. (1996). Importance measures in global sensitivity analysis of nonlinear models. Reliability Engineering & System Safety, 52(1), 1–17. doi:10.1016/0951-8320(96)00002-6.

Hong, C., Ibaraki, S., & Matsubara, A. (2011). Influence of position-dependent geometric errors of rotary axes on a machining test of cone frustum by five-axis machine tools. Precision Engineering, 35(1), 1–11. doi:10.1016/j.precisioneng.2010.09.004.

Jha, B. K., & Kumar, A. (2003). Analysis of geometric errors associated with five-axis machining center in improving the quality of cam profile. International Journal of Machine Tools and Manufacture, 43(6), 629–636. doi:10.1016/S0890-6955(02)00268-7.

Karadeniz, H., Toğan, V., & Vrouwenvelder, T. (2009). An integrated reliability-based design optimization of offshore towers. Reliability Engineering & System Safety, 94(10), 1510–1516.

Karandikar, J. M., Abbas, A. E., & Schmitz, T. L. (2014). Tool life prediction using Bayesian updating. Part 2: Turning tool life using a Markov Chain Monte Carlo approach. Precision Engineering, 38(1), 18–27.

Khan, A. W. (2010). Calibration of 5-axis machine tools. Beijing: Beihang University.

Kim, K., & Kim, M. K. (1991). Volumetric accuracy analysis based on generalized geometric error model in multi-axis machine tools. Mechanism and Machine Theory, 26(2), 207–219. doi:10.1016/0094-114X(91)90084-H.

Kiureghian, A. D., & Dakessian, T. (1998). Multiple design points in first and second-order reliability. Structural Safety, (97), 37–49.

Lamond, B. F., Sodhi, M. S., Noël, M., & Assani, O. A. (2014). Dynamic speed control of a machine tool with stochastic tool life: Analysis and simulation. Journal of Intelligent Manufacturing, 25(5), 1153–1166.

Lee, R. S., & Lin, Y. H. (2012). Applying bidirectional kinematics to assembly error analysis for five-axis machine tools with general orthogonal configuration. The International Journal of Advanced Manufacturing Technology, 62(9–12), 1261–1272. doi:10.1007/s00170-011-3860-y.

Lei, W. T., & Hsu, Y. Y. (2003). Accuracy enhancement of five-axis CNC machines through real-time error compensation. International Journal of Machine Tools and Manufacture, 43(9), 871–877. doi:10.1016/S0890-6955(03)00089-0.

Li, B., Hong, J., & Liu, Z. (2014). Stiffness design of machine tool structures by a biologically inspired topology optimization method. International Journal of Machine Tools and Manufacture, 84, 33–44.

Lin, P. D., & Tzeng, C. S. (2008). Modeling and measurement of active parameters and workpiece home position of a multi-axis machine tool. International Journal of Machine Tools and Manufacture, 48(3–4), 338–349. doi:10.1016/j.ijmachtools.2007.10.004.

Lin, T.-R. (1998). Reliability and failure of face-milling tools when cutting stainless steel. Journal of Materials Processing Technology, 79(1), 41–46.

Liu, H., Li, B., Wang, X., & Tan, G. (2011). Characteristics of and measurement methods for geometric errors in CNC machine tools. The International Journal of Advanced Manufacturing Technology, 54(1–4), 195–201. doi:10.1007/s00170-010-2924-8.

Liu, Y. W. (2000). Applications of multi-body dynamics in the field of mechanical engineering. Chinese Journal of Mechanical Engineering, 11(1), 144–149.

Mehrabi, M. G., O’Neal, G., Min, B.-K., Pasek, Z., Koren, Y., & Szuba, P. (2002). Improving machining accuracy in precision line boring. Journal of Intelligent Manufacturing, 13(5), 379–389.

Mullany, B. A. (2008). Monte Carlo analysis of machine tool positional accuracy and repeatibility standards. Transactions of the North American Manufacturing Research Institution of SME, 36(10473025), 309–316.

Ning, F., Peiquan, G., & Zihui, G. (2008.) Calculation of life reliability of ceramic cutting tools by Monte Carlo simulation. In IEEE Conference on Control and Decision, CCDC 2008. Chinese, 2008 (pp. 1892–1895).

Rahman, M., Heikkala, J., & Lappalainen, K. (2000). Modeling, measurement and error compensation of multi-axis machine tools. Part I: theory. International Journal of Machine Tools and Manufacture, 40(10), 1535–1546. doi:10.1016/S0890-6955(99)00101-7.

Ramesh, R., Mannan, M. A., & Poo, A. N. (2000). Error compensation in machine tools: A review—Part I: geometric, cutting-force induced and fixture-dependent errors. International Journal of Machine Tools and Manufacture, 40(9), 1235–1256. doi:10.1016/S0890-6955(00)00009-2.

Sarkar, S., & Dey, P. P. (2015). Tool path generation for algebraically parameterized surface. Journal of Intelligent Manufacturing, 26(2), 415–421. doi:10.1007/s10845-013-0799-x.

Shin, Y. C., Chin, H., & Brink, M. J. (1991). Characterization of CNC machining centers. Journal of Manufacturing Systems, 10(5), 407–421. doi:10.1016/0278-6125(91)90058-A.

Song, S., Lu, Z., Zhang, W., & Ye, Z. (2009). Reliability and sensitivity analysis of transonic flutter using improved line sampling technique. Chinese Journal of Aeronautics, 22(5), 513–519. doi:10.1016/S1000-9361(08)60134-X.

Soons, J. A., Theuws, F. C., & Schellekens, P. H. (1992). Modeling the errors of multi-axis machines: A general methodology. Precision Engineering, 14(1), 5–19. doi:10.1016/0141-6359(92)90137-L.

Stryczek, R. (2014). A metaheuristic for fast machining error compensation. Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0945-0.

Tang, J. (2001). Mechanical system reliability analysis using a combination of graph theory and Boolean function. Reliability Engineering & System Safety, 72(1), 21–30.

Tsutsumi, M., & Saito, A. (2004). Identification of angular and positional deviations inherent to 5-axis machining centers with a tilting-rotary table by simultaneous four-axis control movements. International Journal of Machine Tools and Manufacture, 44(12–13), 1333–1342. doi:10.1016/j.ijmachtools.2004.04.013.

Wang, J., & Guo, J. (2013). Algorithm for detecting volumetric geometric accuracy of NC machine tool by laser tracker. Chinese Journal of Mechanical Engineering, 26(1), 166–175. doi:10.3901/CJME.2013.01.166.

Wei-Liang, X., & Qi-Xian, Z. (1989). Probabilistic analysis and Monte Carlo simulation of the kinematic error in a spatial linkage. Mechanism and Machine Theory, 24(1), 19–27.

Xiao, N.-C., Huang, H.-Z., Wang, Z., Pang, Y., & He, L. (2011). Reliability sensitivity analysis for structural systems in interval probability form. Structural and Multidisciplinary Optimization, 44(5), 691–705. doi:10.1007/s00158-011-0652-9.

Xu, C., & Gertner, G. (2007). Extending a global sensitivity analysis technique to models with correlated parameters. Computational Statistics & Data Analysis, 51(12), 5579–5590. doi:10.1016/j.csda.2007.04.003.

Zeroudi, N., & Fontaine, M. (2015). Prediction of tool deflection and tool path compensation in ball-end milling. Journal of Intelligent Manufacturing, 26(3), 425–445. doi:10.1007/s10845-013-0800-8.

Zhang, D., Wang, L., Gao, Z., & Su, X. (2013). On performance enhancement of parallel kinematic machine. Journal of Intelligent Manufacturing, 24(2), 267–276.

Zhang, Y. M., Wen, B. C., & Liu, Q. L. (2003). Reliability sensitivity for rotor-stator systems with rubbing. Journal of Sound and Vibration, 259(5), 1095–1107. doi:10.1006/jsvi.2002.5117.

Zhu, S., Ding, G., Qin, S., Lei, J., Zhuang, L., & Yan, K. (2012). Integrated geometric error modeling, identification and compensation of CNC machine tools. International Journal of Machine Tools and Manufacture, 52(1), 24–29. doi:10.1016/j.ijmachtools.2011.08.011.

Acknowledgments

The authors are most grateful to the National High Technology Research and Development Program 863(SS2012AA040704), the Leading Talent Project of Guangdong Province, Beijing Nova Program (xxjh2015106), Open Project of State Key Lab of Digital Manufacturing Equipment & Technology (Huazhong University of Science and Technology), Shantou Light Industry Equipment Research Institute of science and technology Correspondent Station (2013B090900008), which they support the research presented in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Q., Zhao, H., Zhao, Y. et al. Machining accuracy reliability analysis of multi-axis machine tool based on Monte Carlo simulation. J Intell Manuf 29, 191–209 (2018). https://doi.org/10.1007/s10845-015-1101-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1101-1