Abstract

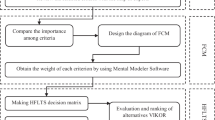

Given that there is a large gap between the results of group-based decision-making and reality when using the same set of evaluation criteria to select the tool for lean management, this research uses the improved VIKOR method to select the tool based on an examination of a yogurt production line. Consequently, (1) the improved VIKOR method is able to make priority decisions, according to different evaluation criteria. On this basis, we develop a tool selection model for lean management which is able to avoid the limitations of using the same set of evaluation criteria to measure all alternative tools; (2) the selection model is not sensitive to the coefficient of the selection mechanism and the weight of the evaluation criteria, and so its results are very stable; and (3) the selection model ensures the maximizing utility of group based decision-making and minimizing regret of individuals, in other words, avoiding the inferior solutions.

Similar content being viewed by others

References

Almomani, M. A., Aladeemy, M., Abdelhadi, A., & Mumani, A. (2013). A proposed approach for setup time reduction through integrating conventional SMED method with multiple criteria decision-making techniques. Computers and Industrial Engineering, 66(2), 461–469.

Amin, M. A., & Karim, M. A. (2013). A time-based quantitative approach for selecting lean strategies for manufacturing organizations. International Journal of Production Research, 51(4), 1146–1167.

Anvari, A., Zulkifli, N., & Arghish, O. (2014a). Application of a modified VIKOR method for decision-making problems in lean tool selection. The International Journal of Advanced Manufacturing Technology, 71(5–8), 829–841.

Anvari, A., Zulkifli, N., Sorooshian, S., & Arghish, O. (2014b). An integrated design methodology based on the use of group AHP-DEA approach for measuring lean tools efficiency with undesirable output. The International Journal of Advanced Manufacturing Technology, 70(9–12), 2169–2186.

Avikal, S., Jain, R., Mishra, P. K., & Yadav, H. C. (2013). A heuristic approach for U-shaped assembly line balancing to improve labor productivity. Computers and Industrial Engineering, 64(4), 895–901.

Ayag, Z. (2005). An integrated approach to evaluating conceptual design alternatives in a new product development environment. International Journal of Production Research, 43(4), 687–713.

Ayag, Z. (2007). A hybrid approach to machine-tool selection through AHP and simulation. International Journal of Production Research, 45(9), 2029–2050.

Chang, C. L. (2010). A modified VIKOR method for multiple criteria analysis. Environmental Monitoring and Assessment, 168(1–4), 339–344.

Hines, P., & Rich, N. (1997). The seven value stream mapping tools. International Journal of Operations and Production Management, 17(1), 46–64.

Hoss, M., & Caten, C. S. (2013). Lean schools of thought. International Journal of Production Research, 51(11), 3270–3282.

Koukoulaki, Theoni. (2014). The impact of lean production on musculoskeletal and psychosocial risks: An examination of sociotechnical trends over 20 years. Applied Ergonomics, 45(2), 198–213.

Leng, J. W., Jiang, P. Y., & Ding, K. (2014). Implementing of a three-phase integrated decision support model for parts machining outsourcing. International Journal of Production Research, 52(12), 3614–3636.

Marvel, J. H., & Standridge, C. R. (2009). Simulation-enhanced lean design process. Journal of Industrial Engineering and Management, 2(1), 90–113.

Niu, Z. W., & Jing, S. W. (2014). Discussion on management innovation model of manufacturing enterprises based on lean production. Journal of Tianjin University, 16(6), 481–487.

Opricovic, S., & Tzeng, G. H. (2007). Extended VIKOR method in comparison with outranking methods. European Journal of Operational Research, 178(2), 514–529.

Prasad, B. (1995). JIT quality matrices for strategic planning and implementation. International Journal of Operations and Production Management, 15(9), 116–142.

Qi, E. S., & Liu, L. (2013). Roadmap for management innovation success: Product life cycle oriented lean management innovation in china. Beijing: Tsinghua University Press. (in Chinese).

Shemshadi, A., Shirazi, H., & Toreihi, M. (2011). A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Systems with Applications, 38(10), 12160–12167.

Simanaviciene, R., & Ustinovichius, L. (2010). Sensitivity analysis for multiple criteria decision making methods: TOPSIS and saw. Procedia-Social and Behavioral Sciences, 2(6), 7743–7744.

Steinlicht, C. L. (2011). Lean production and the organizational life cycle: A survey of lean tool effectiveness in young and mature organizations, doctoral dissertation. US: Capella University.

Tiwari, A., Turner, C., & Sackett, P. (2007). A framework for implementing cost and quality practices within manufacturing. Journal of Manufacturing Technology Management, 18(6), 731–760.

Vinodh, S., & Chintha, S. K. (2009). Leanness assessment using multi grade fuzzy approach. International Journal of Production Research, 49(2), 431–445.

Vinodh, S., Shivraman, K. R., & Viswesh, S. (2012). AHP-based lean concept selection in a manufacturing organization. Journal of Manufacturing Technology Management, 23(1), 124–136.

Vinodh, S., Thiagarajan, A., & Mulanjur, G. (2014). Lean concept selection using modified fuzzy TOPSIS: A case study. International Journal of Services and Operations Management, 18(3), 342–357.

Vinodh, S., & Vimal, K. E. K. (2012). Thirty criteria based leanness assessment using fuzzy logic approach. The International Journal of Advanced Manufacturing Technology, 60(9–12), 1185–1195.

Womack, J. P., Jones, D. T., & Roos, D. (1990). The machine that changed the world. New York: Macmillan Publishing Company.

Yang, Y. P. O., Shieh, H. M., Leu, J. D., & Tzeng, G. H. (2009). A VIKOR-based multiple criteria decision method for improving information security risk. International Journal of Information Technology and Decision Making, 8(2), 267–287.

Yuan, Y., Guan, T., Yan, X. B., et al. (2014). Based on hybrid VIKOR method decision making model for supplier Selection. Control and Decision, 29(3), 551–560.

Zandi, A., & Roghanian, E. (2013). Extension of fuzzy ELECTRE based on VIKOR method. Computers and Industrial Engineering, 66(2), 258–263.

Acknowledgments

This research was supported by the National Natural Science Foundation of China under Grant No.71071107.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jing, S., Niu, Z. & Chang, PC. The application of VIKOR for the tool selection in lean management. J Intell Manuf 30, 2901–2912 (2019). https://doi.org/10.1007/s10845-015-1152-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1152-3