Abstract

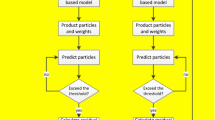

This paper presents a probabilistic model based approach for machinery condition prognosis based on particle filter by integrating physical knowledge with in-process measurements into a state space framework to account for uncertainty and nonlinearity in machinery degradation process. One limitation of conventional particle filter is that condition prognosis is performed based on the model with predetermined parameters obtained from simulation studies or lab-controlled tests. Due to the stochastic nature of machinery defect propagation under varying operating conditions, model parameters may vary in practice which causes prediction errors. To address it, an integrated state prediction and parameter estimation framework based on particle filter and expectation-maximization algorithm is formulated and investigated. The model parameters are adaptively estimated based on expectation-maximization algorithm utilizing hidden degradation state and available in-process measurements. Particle filter is then performed on the identified model with estimated parameters following Bayesian inference scheme to improve the robustness and accuracy of machinery condition prognosis. The effectiveness of the developed method is demonstrated through a simulation study and an experimental run-to-failure bearing test in a wind turbine.

Similar content being viewed by others

References

An, D., Choi, J. H., & Kim, N. H. (2013). Prognostics 101: A tutorial for particle filter-based prognostics algorithm using Matlab. Reliability Engineering & System Safety, 115, 161–169.

Arulampalam, M. S., Maskell, S., Gordon, N., & Clapp, T. (2002). A tutorial on particle filters for online nonlinear/Non-Gaussian Bayesian tracking. IEEE Transactions on Signal Processing, 50(2), 174–188.

Basin, M. V., Loukianov, A. G., & Hernandez-Gonzalez, M. (2013). Joint state and parameter estimation for uncertain nonlinear polynomial systems. International Journal of Systems Science, 44(7), 1200–1208.

Bechhoefer, E., & Bernhard, A. P. F. (2007). A generalized process for optimal threshold setting in HUMS. In Proceedings of 2007 IEEE Aerospace Conference (pp. 1–9.). Big Sky, MT, March 3–10.

Beckhoefer, E., He, D., & Dempsey, R. (2011). Gear health threshold setting based on a probability of false alarm. In Proceedings of Annual Conference of the Prognostics and Health Management Society (pp. 1–7). Montreal, Quebec, Canada, September 25–29.

Benkedjouh, T., Medjaher, K., Zerhouni, N., & Rechak, S. (2015). Health assessment and life prediction of cutting tools based on support vector regression. Journal of Intelligent Manufacturing, 26, 213–223.

Bousdekis, A., Magoutas, B., Apostolou, D., & Mentzas, G. (2016). Review, analysis and synthesis of prognostic-based decision support methods for condition based maintenance. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-015-1179-5.

Dempster, A., Laird, N., & Rubin, D. (1977). Maximum likelihood from incomplete data via the EM algorithm. Journal of the Royal Statistical Society, Series B, 39(1), 1–38.

Gokulachandran, J., & Mohandas, K. (2015). Comparative study of two soft computing techniques for the prediction of remaining useful life of cutting tools. Journal of Intelligent Manufacturing, 26, 255–268.

Gordon, N. J., Salmond, D. J., & Smith, A. F. M. (1993). Novel approach to nonlinear/non-Gaussian Bayesian state estimation. IEE Proceedings-F Radar and Signal Processing, 140(2), 107–113.

Heng, A., Zhang, S., Tan, A. C. C., & Mathew, J. (2009). Rotating machinery prognostics: State of the art, challenges, and opportunities. Mechanical Systems and Signal Processing, 23, 724–739.

Hue, C., Le Cadre, J. P., & Perez, P. (2002). Tracking multiple objects with particle filtering. IEEE Transactions on Aerospace and Systems, 38(3), 791–812.

Julier, S. J., & Uhlmann, J. K. (1997). A new extension of Kalman Filter to nonlinear systems. In Proceedings of 11th International Symposium on Aerospace/Defense sensing, simulation and controls, multi sensor fusion, tracking and resource management (pp. 1–12).

Jurkovie, Z., Cukor, G., Brezocnik, M., & Brajkovie, T. (2016). A comparison of machine learning methods for cutting parameters prediction in high speed turning process. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-016-1206-1.

Kalman, R. E. (1960). A new approach to linear filtering and prediction problems. Transactions of the ASME-Journal of Basic Engineering, 82, 35–45.

Kwok, C., Fox, D., & Meila, M. (2003). Adaptive real-time particle filters for robot localization. In Proceedings of the 2003 IEEE International Conference on Robotics & Automation (pp. 2836-2841). Taipei, Taiwan, September 14–19.

Lever, P. J. A., Marefat, M. M., & Ruwani, T. (1997). A machine learning approach to tool wear behavior operational zones. IEEE Transactions on Industry Applications, 33(1), 264–73.

Liao, L. (2014). Discovering prognostic features using genetic programming in remaining useful life prediction. IEEE Transactions on Industrial Electronics, 61(5), 2464–2472.

Li, Y., Billington, S., Zhang, C., Kurfess, T., Danyluk, S., & Liang, S. (1999). Dynamic prognostic prediction of defect propagation on rolling element bearings. Tribology Transactions, 42(2), 385–392.

Liu, J., & West, M. (2001). Combined parameter and state estimation in simulation-based filtering. In Sequential Monte Carlo Methods in Practice (pp. 197–223). New York: Springer.

Liu, J., Wang, W., & Ma, F. (2011). A regularized auxiliary particle filtering approach for system state estimation and battery life prediction. Smart Materials and Structures, 20, 1–9.

Malhi, A., Yan, R., & Gao, R. X. (2011). Prognosis of defect propagation based on recurrent neural networks. IEEE Transactions on Instrumentation and Measurement, 60(3), 703–711.

Mehta, P., Werner, A., & Mears, L. (2015). Condition based maintenance-systems integration and intelligence using Bayesian classification and sensor fusion. Journal of Intelligent Manufacturing, 26, 331–346.

Mkhadri, A. (1998). On the rate of convergence of the ECME algorithm. Statistics & Probability Letters, 37(1), 81–87.

Moon, T. K. (1996). The expectation-maximization algorithm. IEEE Signal Processing Magazine, 13(6), 47–60.

Orchard, M. E., & Vachtsevanos, G. J. (2009). A particle-filtering approach for on-line fault diagnosis and failure prognosis. Transactions of the Institute of Measurement and Control, 31(3/4), 221–246.

Paris, P. C., Gomez, M. P., & Anderson, W. E. (1961). A rational analytic theory of fatigue. The Trend in Engineering, 13, 9–14.

Pedregal, D. J., & Carnero, M. C. (2006). State space models for condition monitoring: A case study. Reliability Engineering and System Safety, 91, 171–180.

Peng, Y., & Dong, M. (2011). A prognosis method using age-dependent hidden semi-Markov model for equipment health prediction. Mechanical Systems and Signal Processing, 25(1), 237–252.

Peng, Y., Dong, M., & Zuo, M. J. (2010). Current status of machine prognostics in condition-based maintenance: A review. International Journal of Advanced Manufacturing Technology, 50, 297–313.

Pham, H. T., & Yang, B. S. (2010). Estimation and forecasting of machine health condition using ARMA/GARCH model. Mechanical Systems and Signal Processing, 24, 546–558.

Qian, N. (1999). On the momentum term in gradient descent learning algorithms. Neural Networks, 12, 145–151.

Ragab, A., Yacout, S., Ouali, M. S., & Osman, H. (2016). Prognostics of multiple failure modes in rotating machinery using a pattern-based classifier and cumulative incidence functions. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-016-1244-8.

Sarkeyli, A., Zain, A. M., & Sharif, S. (2015). A multi-performance prediction model based on ANFIS and new modified-GA for machining processes. Journal of Intelligent Manufacturing, 26, 703–716.

Schon, T. B., Wills, A., & Ninness, B. (2011). System identification of nonlinear state-space models. Automatica, 47(1), 39–49.

Storvik, G. (2002). Particle filters for state-space models with the presence of unknown static parameters. IEEE Transactions on Signal Processing, 50(2), 281–289.

Teti, R., Jemielniak, K., O’Donnell, G., & Dornfeld, D. (2010). Advanced monitoring of machining operations. CIRP Annals-Manufacturing Technology, 59, 717–739.

Vogl, G. W., Weiss, B. A., & Helu, M. (2016). A review of diagnostic and prognostic capabilities and best practices for manufacturing. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-016-1228-8.

Wang, J., & Gao, R. X. (2013). Multiple model particle filtering for bearing life prognosis. In Proceedings of 2013 IEEE International Conference on Prognostics and Health Management (PHM 2013) (pp. 1–6). Gaithersburg, Maryland, USA, June 24–27.

Wang, J., Gao, R. X., & Yan, R. (2014). Multi-scale enveloping order spectrogram for rotating machine health diagnosis. Mechanical Systems and Signal Processing, 46(1), 28–44.

Zhang, Z., Wang, Y., & Wang, K. (2013). Fault diagnosis and prognosis using wavelet packet decomposition, Fourier transform, and artificial neural network. Journal of Intelligent Manufacturing, 24, 1213–1227.

Zhao, Z., Huang, B., & Liu, F. (2013). Parameter estimation in batch process using EM algorithm with particle filter. Computers and Chemical Engineering, 57, 159–172.

Zio, E., & Peloni, G. (2011). Particle filtering prognostics estimation of the remaining useful life of nonlinear components. Reliability Engineering and System Safety, 96, 403–409.

Acknowledgments

This work has been partially supported by the National Science Foundation of US (CMMI-1300999), the National Science foundation of China (Nos. 51504274 and 51674277), the National Key Research and Development Program of China (No. 2016YFC0802105), and the Science Foundation of China University of Petroleum (Nos. 2462014YJRC039 and 2462015YQ0403). Experimental support from Dr. Eric Bechhoefer (NRG Systems Company), and support from the Xi’an Jiaotong University for Zhaoyan Fan are sincerely appreciated. The authors would like to thank the anonymous reviewers for their constructive comments, which have helped improve the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Gao, R.X., Yuan, Z. et al. A joint particle filter and expectation maximization approach to machine condition prognosis. J Intell Manuf 30, 605–621 (2019). https://doi.org/10.1007/s10845-016-1268-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-016-1268-0