Abstract

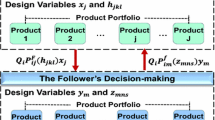

Product family design (PFD) has been traditionally tackled as a single-level multi-objective optimization problem. This paper reveals a complex type of leader-follower joint optimization (LFJO) problems that are widely observed for PFD. Leader-follower decision making is inherent in product family optimization that involves multiple decision makers and encompasses different levels of decision hierarchy, in which many conflicting goals compete to arrive at equilibrium solutions. It is important for PFD to explicitly model such leader-follower decisions in line with a Stackelberg game. Consistent with multiple decision makers across different stages of the PFD process and multiple levels of the PFD decision hierarchy, this paper classifies the leader-follower decisions of PFD using a quartet grid, which serves as a reference model for conceptualization of diverse types of LFJO problems associated with PFD. Coinciding with the bilevel decision structure of game theoretic optimization, each LFJO problem formulation defined from the quartet grid can be quantitatively mapped to a bilevel programming mathematical model to be solved effectively by nested genetic algorithms. A case study of gear reducer PFD is presented to demonstrate the rational and potential of the LFJO quartet grid for dealing with game-theoretic optimization problems underpinning PFD decisions.

Similar content being viewed by others

References

Adelson, B. (1999). Developing strategic alliances: A framework for collaborative negotiation in design. Research in Engineering Design, 11(3), 133–144.

Anandalingam, G., & White, D. J. (1990). A solution method for the linear static Stackelberg problem using penalty functions. IEEE Transactions on Automatic Control, 35(10), 1170–1173.

Bahler, D., Dupont, C., & Bowen, J. (1995). Mixed quantitative/qualitative method for evaluating compromise solutions to conflicts in collaborative design. Artificial Intelligence for Engineering Design, Analysis and Manufacturing, 9, 325–33.

Balesdent, M., Bérend, N., Dépincé, P., et al. (2012). A survey of multidisciplinary design optimization methods in launch vehicle design. Structural and Multidisciplinary Optimization, 45(5), 619–642.

Bard, J. F. (1998). Practical bilevel optimization: Algorithms and applications. Dordrecht: Kluwer Academic Publishers.

Bialas, W. F., & Karwan, M. H. (1982). On two-level optimization. IEEE Transactions on Automatic Control, 27(1), 211–214.

Blackenfelt, M. (2000). Design of robust interfaces in modular products. In ASME design engineering technical conferences, Baltimore, MD, DETC00/DAC-14486.

Bracken, J., & McGill, J. (1973). The equivalence of two mathematical programs with optimization problems in the constraints. Operations Research, 21, 37–44.

Chu, C., Li, W., Jiao, R. J., et al. (2013). Design chain management: Bridging the gap between engineering and management. Journal of Intelligent Manufacturing, 24, 541–544.

Coello, C. A. C., & Christiansen, A. D. (1999). Moses: A multiobjective optimization tool for engineering design. Engineering Optimization, 31, 337–368.

Colson, B., Marcotte, P., & Savard, G. (2007). An overview of bilevel optimization. Annals of Operations Research, 153, 235–256.

Cooper, S., & Taleb-Bendiab, A. (1998). Consensus: Multi-party negotiation support for conflict resolution in concurrent engineering design. Journal of Intelligent Manufacturing, 9, 155–159.

Dai, Z., & Scott, M. J. (2007). Product platform design through sensitivity analysis and cluster analysis. Journal of Intelligent Manufacturing, 18(1), 97–113.

Deciu, E. R., Ostrosi, E., Ferney, M., et al. (2005). Configurable product design using multiple fuzzy models. Journal of Engineering Design, 16(2), 209–233.

Dempe, S. (2003). Annotated bibliography on bilevel programming and mathematical programs with equilibrium constraints. Optimization, 52, 333–359.

de Weck, O. L., Suh, E. S., & Chang, D. (2003). Product family and platform portfolio optimization. In ASME design engineering technical conferences, DETC03/DAC-48721, Chicago, IL.

D’souza, B., & Simpson, T. W. (2003). A genetic algorithm based method for product family design optimization. Engineering Optimization, 35(1), 1–18.

Du, G., Jiao, R. J., & Chen, M. (2014). Joint optimization of product family configuration and scaling design by Stackelberg game. European Journal of Operational Research, 232, 330–341.

Du, G., Yu, J., Sun, L., et al. (2013). Leader-followers joint optimization of product family configuration and supply chain design. International Journal of Knowledge, Innovation and Entrepreneurship, 1(1), 6–23.

Erens, F., & Verhulst, K. (1997). Architectures for product families. Computer in Industry, 33, 165–178.

Erlandsson, A., Erixon, G., & Ostgren, B. (1992). Product modules the link between QFD and DFA. Newport, RI: The International Forum on Product Design for Manufacture and Assembly.

Fellini, R., Kokkolaras, M., & Papalambros, P. Y. (2006). Quantitative platform selection in optimal design of product families, with application to automotive engine design. Journal of Engineering Design, 17(5), 429–446.

Fine, C. H. (2005). Are you modular or integral? Be sure your supply chain knows. Strategy + Business, 2005(39), 1–8.

Fortuny-Amat, J., & McCarl, B. (1981). A representation and economic interpretation of a two-level programming problem. Journal of the Operational Research Society, 32(9), 783–792.

Fujita, K., & Yoshida, H. (2004). Product variety optimization simultaneously designing module combination and module attributes. Concurrent Engineering: Research and Application, 12(2), 105–118.

Gu, X., Renaud, J., Ashe, L., et al. (2002). Decision-based collaborative optimization. Journal of Mechanical Design, 124, 1–13.

Hernandez, G., Seepersad, C. C., & Mistree, F. (2002). Designing for maintenance: A game theoretic approach. Engineering Optimization, 34, 561–577.

Huang, G. Q., Li, L., & Schulze, L. (2008). Genetic algorithm-based optimisation method for product family design with multi-level commonality. Journal of Engineering Design, 19(5), 401–416.

Jeroslow, R. G. (1985). The polynomial hierarchy and a simple model for competitive analysis. Mathematical Programming, 32(2), 146–164.

Ji, Y., Jiao, R. J., & Chen, L. (2013). Green modular design for material efficiency: A leader follower joint optimization model. Journal of Cleaner Production, 41, 187–201.

Jiao, R. J., Tseng, M. M., Duffy, V. G., et al. (1998). Product family modeling for mass customization. Computers and Industrial Engineering, 35(3–4), 495–498.

Jiao, R. J., & Zhang, Y. (2005). Product portfolio planning with customer-engineering interaction. IIE Transactions, 37(9), 801–814.

Jiao, R. J., Simpson, T. W., & Siddique, Z. (2007). Product family design and platform-based product development: A state-of-the-art review. Journal of Intelligent Manufacturing, 18, 5–29.

Jiao, R. J., & Zhang, Y. (2007). A generic genetic algorithm for product family design. Journal of Intelligent Manufacturing, 18, 233–247.

Jiao, J., & Tseng, M. M. (2000). Fundamentals of product family architecture. Integrated Manufacturing Systems, 11(7), 469–483.

Jiao, R. J., & Tseng, M. M. (2013). On equilibrium solutions to joint optimization problems in engineering design. CIRP Annals—Manufacturing Technology, 62, 155–158.

Jin, M., & Chen, R. (2008). The platform configuration for product family production. In: 4 th international conference on wireless communications, networking and mobile computing, Dalian (pp. 19–21).

Kalashnikov, V. V., Dempe, S., Perez-Valdes, G. A., et al. (2015). Bilevel programming and applications. Mathematical Problems in Engineering, 310301, 1–16.

Kim, H. M. (2001). Target cascading in optimal system design. Ph.D. Diss., University of Michigan.

Kim, H. M., Michelena, N. F., Papalambros, P. Y., et al. (2003). Target cascading in optimal system design. ASME Journal of Mechanical Design, 125(3), 474–480.

Kodiyalam, S., & Sobieszczanski-Sobieski, J. (2001). Multidisciplinary design optimization-some formal methods, framework requirements, and application to vehicle design. International Journal of Vehicle Design, 25, 3–22.

Kristianto, Y., Helo, P., & Jiao, R. J. (2013). Mass customization design of engineer-to-order products using Benders’ decomposition and bi-level stochastic programming. Journal of Intelligent Manufacturing, 24, 961–975.

Kumar, D., Chen, W., & Simpson, T. W. (2009). A Market-driven approach to product family design. International Journal of Production Research, 47(1), 71–104.

Li, X., Zhou, X., & Ruan, X. (2002). Conflict management in closely coupled collaborative design system. International Journal of Computer Integrated Manufacturing, 15(4), 345–352.

Lynwander, P. (1983). Gear Drive Systems: Design and Application. New York, NY: Marcel Dekker. ISBN-13: 978–0824718961.

Marinelli, F., de Weck, O., et al. (2009). A general framework for combined module- and scale-based product platform design. In Second international symposium on engineering systems.

Martins, J. R., & Lambe, A. B. (2013). Multidisciplinary design optimization: A survey of architectures. AIAA Journal, 51(9), 2049–2075.

McAllister, C. D., & Simpson, T. W. (2003). Multidisciplinary robust design optimization of an internal combustion engine. Journal of Mechanical Design, 125(1), 124–130.

Messac, A., Martinez, M. P., & Simpson, T. W. (2002a). Effective product family design using physical programming and the product platform concept exploration method. Engineering Optimization, 3(3), 245–261.

Messac, A., Martinez, M. P., & Simpson, T. W. (2002b). A penalty function for product family design using physical programming. ASME Journal of Mechanical Design, 124(2), 164–172.

Mistree, F., Hughes, O. F., & Bras, B. (1993). The compromise decision support problem and the adaptive linear programming algorithm. In M. P. Kamat (Ed.), Structural optimization: Status and promise (pp. 247–289). Washington, DC: AIAA.

Nayak, R. U., Chen, W., & Simpson, T. W. (2002). A variation-based method for product family design. Journal of Engineering Optimization, 34(1), 65–81.

Newcomb, P. J., Bras, B., & Rosen, D. W. (1996). Implications of modularity on product design for the life cycle. In ASME design engineering technical conferences, DETC96/DTM-1516, Irvine, CA.

Nomaguchi, Y., Nakashima, K., & Fujita, K. (2009). Proposal of management framework of engineering analysis modeling knowledge for design validation. In Proceedings of the 9th Japan-Korea Design Engineering Workshop (pp. 67–72), Yomitan, Okinawa, Japan.

Papalambros, P. Y., & Chirehdast, M. (1990). An integrated environment for structural configuration design. Journal of Engineering Design, 1(1), 73–96.

Roy, R., Hinduja, S., & Teti, R. (2008). Recent advances in engineering design optimization: Challenges and future trends. Manufacturing Technology, 57(2), 697–715.

Sakawa, M., Katagiri, H., & Matsui, T. (2011). Interactive fuzzy random two-level linear programming through fractile criterion optimization. Mathematical and Computer Modelling, 54(11–12), 3153–63.

Simpson, T. W. (2004). Product platform design and customization: status and promise. Artificial Intelligence for Engineering Design, Analysis and Manufacturing, 18(1), 3–20.

Simpson, T. W., Chen, W., Allen, J. K., et al. (1996). Conceptual design of a family of products through the use of the robust concept exploration method. In 6th AIAA/USAF/NASA/ISSMO Symposium on Multidisciplinary Analysis and Optimization (pp. 1535–1545).

Simpson, T. W., Jiao, R. J., Siddique, Z., & Hölttä-Otto, K. (2014). Advances in product family and product platform design: Methods and applications. Springer. ISBN: 978-1-4614-7936-9.

Simpson, T. W., Maier, J. R. A., & Mistree, F. (2001). Product platform design: Method and application. Research in Engineering Design, 13(1), 2–22.

Swaminathan, J. M., & Lee, H. L. (2003). Design for postponement. In S. Graves & T. de Kok (Eds.), Supply Chain Management—Handbook in OR/MS (Vol. 11, pp. 199–226). Amsterdam: North-Holland.

Talbi, E. G. (2013). A taxonomy of metaheuristics for bi-level optimization. In E. G. Talbi (Ed.), Metaheuristics for bi-level optimization (pp. 1–39). Berlin, Heidelberg: Springer.

Tao, J., & Yu, S. (2012). Incorporating reuse and remanufacturing in product family planning. In M. Matsumoto, Y. Umeda, K. Masui, & S. Fukushige (Eds.), Design for innovative value towards a sustainable society (pp. 795–800). Heidelberg: Springer.

Tappeta, R. V., & Renaud, J. E. (2001). Interactive multiobjective optimization design strategy for decision based design. Journal of Mechanical Design, 123, 205–215.

Ulrich, K., & Eppinger, S. (2011). Product design and development, 5e. New York: McGraw-Hill Higher Education.

von Stackelberg, H. (2011). Market structure and equilibrium, English translation of Stackelberg (1934). Heidelberg: Springer.

Wang, D., Du, G., Jiao, R. J., et al. (2016). A Stackelberg game theoretic model for optimizing product family architecting with supply chain consideration. International Journal of Production Economics, 172, 1–18.

Wikipedia. (2015). Volkswagen Group A platform. http://en.wikipedia.org/wiki/Volkswagen_Group_A_platform.

Yang, D., Jiao, J. R., Ji, Y., et al. (2015). Joint optimization for coordinated configuration of product families and supply chains by a leader-follower Stackelberg game. European Journal of Operational Research, 246(1), 263–280.

Ye, J. J., & Zhu, D. (2010). New necessary optimality conditions for bilevel programs by combining MPEC and the Value Function Approach. SIAM Journal on Optimization, 20(4), 1885–1905.

Yokota, T., Gen, M., & Li, Y. X. (1996). Genetic algorithm for non-linear mixed-integer programming and its applications. Computers & Industrial Engineering, 30(4), 905–917.

Yu, T. L., Yassine, A. A., & Goldberg, D. E. (2003). A genetic algorithm for developing modular product architectures. ASME design engineering technical conferences (pp. 515–524). Chicago: Illinois.

Yu, Y., & Huang, G. Q. (2010). Nash game model for optimizing market strategies, configuration of platform products in a Vendor Managed Inventory (VMI) supply chain for a product family. European Journal of Operational Research, 206(2), 361–373.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was supported by National Natural Science Foundation of China under Project Numbers 71071104 and 71371132.

Rights and permissions

About this article

Cite this article

Du, G., Xia, Y., Jiao, R.J. et al. Leader-follower joint optimization problems in product family design. J Intell Manuf 30, 1387–1405 (2019). https://doi.org/10.1007/s10845-017-1332-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1332-4