Abstract

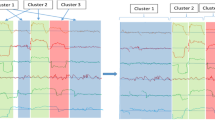

As a part of prognostics and health management (PHM), fault detection has been used in many fields to improve the reliability of the system and reduce the manufacturing costs. Due to the complexity of the system and the richness of the sensors, fault detection still faces some challenges. In this paper, we propose a data-driven method in a self-supervised manner, which is different from previous prognostic methods. In our algorithm, we first extract feature indices of each batch and concatenate them into one feature vector. Then the principal components are extracted by Kernel PCA. Finally, the fault is detected by the reconstruction error in the feature space. Samples with high reconstruction error are identified as faulty. To demonstrate the effectiveness of the proposed algorithm, we evaluate our algorithm on a benchmark dataset for fault detection, and the results show that our algorithm outperforms other fault detection methods.

Similar content being viewed by others

References

Aminzadeh, M., & Kurfess, T. R. (2018). Online quality inspection using Bayesian classification in powder-bed additive manufacturing from high-resolution visual camera images. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1412-0.

Benkedjouh, T., Medjaher, K., Zerhouni, N., & Rechak, S. (2015). Health assessment and life prediction of cutting tools based on support vector regression. Springer, 26, 213–223.

Farhat, A., Guyeux, C., Makhoul, A., Jaber, A., Tawil, R., & Hijazi, A. (2017). Impacts of wireless sensor networks strategies and topologies on prognostics and health management. Journal of Intelligent Manufacturing. https://doi.org/10.1007/10845-017-1377-4.

Fu, K. C., Ming, Z., Liu, P., & Wang, G. J. (2012). Incremental fault diagnosis for nonlinear processes. Advanced Materials Research, 433, 6430–6436.

Garca, V., Snchez, J. S., Rodrguez-Picn, L. A., Mndez-Gonzlez, L. C., & de Jess Ochoa-Domnguez, H. (2018). Using regression models for predicting the product quality in a tubing extrusion process. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1418-7.

Hassan, A. H., Lambert-Lacroix, S., & Pasqualini, F. (2015). Real-time fault detection in semiconductor using one-class support vector machines. International Journal of Computer Theory and Engineering, 7(3), 191–196.

He, Y., & Kusiak, A. (2018). Performance assessment of wind turbines: Data-derived quantitative metrics. IEEE Transactions on Sustainable Energy, 9(1), 65–73.

He, Q. P., & Wang, J. (2007). Fault detection using the k-nearest neighbor rule for semiconductor manufacturing processes. IEEE Transactions on Semiconductor Manufacturing, 20(4), 345–354.

He, Q. P., & Wang, J. (2010). Large-scale semiconductor process fault detection using a fast pattern recognition-based method. IEEE Transactions on Semiconductor Manufacturing, 23(2), 194–200.

He, Q. P., & Wang, J. (2011). Statistics pattern analysis: A new process monitoring framework and its application to semiconductor batch processes. AIChE Journal, 57(1), 107–121.

Hoffmann, H. (2007). Kernel PCA for novelty detection. Pattern Recognition, 40(3), 863–874.

Jia, X., Jin, C., Buzza, M., Di, Y., Siegel, D., & Lee, J. (2018). A deviation based assessment methodology for multiple machine health patterns classification and fault detection. Mechanical Systems and Signal Processing, 99, 244–261.

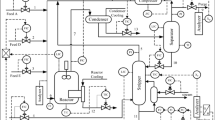

LAM 9600 Metal etch data for fault detection evaluation (1999). available from http://www.eigenvector.com/data/Etch/. Accessed 24 June 2018.

Lin, H., Li, B., Wang, X., Shu, Y., & Niu, S. (2018). Automated defect inspection of LED chip using deep convolutional neural network. Journal of Intelligent Manufacturing, 2018, 1–10.

Li, Y., & Zhang, X. (2014). Diffusion maps based k-nearest-neighbor rule technique for semiconductor manufacturing process fault detection. Chemometrics and Intelligent Laboratory Systems, 136, 47–57.

Lu, N., Gao, F., & Wang, F. (2004). Sub-PCA modeling and on-line monitoring strategy for batch processes. AIChE Journal, 50(1), 255–259.

Mahadevan, S., & Shah, S. L. (2009). Fault detection and diagnosis in process data using one-class support vector machines. Journal of Process Control, 19(10), 1627–1639.

Mosallam, A., Medjaher, K., & Zerhouni, N. (2016). Data-driven prognostic method based on bayesian approaches for direct remaining useful life prediction. Journal of Intelligent Manufacturing, 27(5), 1037–1048.

Santos, P., Maudes, J., & Bustillo, A. (2018). Identifying maximum imbalance in datasets for fault diagnosis of gearboxes. Journal of Intelligent Manufacturing, 29(2), 333–351.

Saucedo-Espinosa, M. A., Escalante, H. J., & Berrones, A. (2017). Detection of defective embedded bearings by sound analysis: A machine learning approach. Journal of Intelligent Manufacturing, 28(2), 489–500.

Schölkopf, B., & Smola, A. J. (2002). Learning with Kernels: Support Vector Machines, Regularization, Optimization and Beyond. Cambridge, MA: MIT Press.

Schölkopf, B., Smola, A., & Müller, K. R. (1998). Nonlinear component analysis as a kernel eigenvalue problem. Neural Computation, 10(5), 1299–1319.

Tao, F., Cheng, J. F., Cheng, Y., Gu, S. X., Zheng, T. Y., & Yang, H. (2017). SDMSim: A manufacturing service supply–demand matching simulator. Robotics and Computer-Integrated Manufacturing, 45(6), 34–46.

Tao, F., Cheng, Y., Da Xu, L., Zhang, L., & Li, B. H. (2014a). CCIoT-CMfg: Cloud computing and internet of things-based cloud manufacturing service system. IEEE Transactions on Industrial Informatics, 10(2), 1435–1442.

Tao, F., Qi, Q. L., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal of Manufacturing Systems,. https://doi.org/10.1016/j.jmsy.2018.01.006.

Tao, F., Zuo, Y., Da Xu, L., & Zhang, L. (2014b). Iot-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Transactions on Industrial Informatics, 10(2), 1547–1557.

Thieullen, A., Ouladsine, M., & Pinaton, J. (2012). A survey of health indicators and data-driven prognosis in semiconductor manufacturing process. IFAC Proceedings Volumes, 45(20), 19–24.

Wang, S., Chang, Y. Q., Zhao, Z., & Wang, F. L. (2012). Multi-phase MPCA modeling and application based on an improved phase separation method. International Journal of Control, Automation, and Systems, 10(6), 1136.

Wang, T., Chen, Y., Qiao, M., & Snoussi, H. (2017). A fast and robust convolutional neural network-based defect detection model in product quality control. The International Journal of Advanced Manufacturing Technology, 94(9–12), 3465–3471.

Wang, R., Edgar, T. F., Baldea, M., Nixon, M., Wojsznis, W., & Dunia, R. (2017). A geometric method for batch data visualization, process monitoring and fault detection. Journal of Process Control,. https://doi.org/10.1016/j.jprocont.2017.05.011.

Wang, T., Qiao, M. N., Zhu, A. C., Niu, Y. D., Li, C., & Snoussi, H. (2018). Abnormal event detection via covariance matrix for optical flow based feature. Multimedia Tools and Applications,. https://doi.org/10.1007/s11042-017-5309-2.

Wang, T., & Snoussi, H. (2014). Unsupervised detection of visual abnormal events via global optical flow orientation histograms. IEEE Transactions on Information Forensics and Security, 9(6), 988–998.

Wise, B. M., Gallagher, N. B., Butler, S. W., White, D. D., & Barna, G. G. (1999). A comparison of principal component analysis, multiway principal component analysis, trilinear decomposition and parallel factor analysis for fault detection in a semiconductor etch process. Journal of Chemometrics, 13(3–4), 379–396.

Wu, D., Jennings, C., Terpenny, J., Gao, R. X., & Kumara, S. (2017). A comparative study on machine learning algorithms for smart manufacturing: Tool wear prediction using random forests. Journal of Manufacturing Science and Engineering, 139(7), 0710181–0710189.

Xia, T., & Xi, L. (2017). Manufacturing paradigm-oriented PHM methodologies for cyber-physical systems. Journal of Intelligent Manufacturing,. https://doi.org/10.1007/s10845-017-1342-2.

Zhao, C., Wang, F., Lu, N., & Jia, M. (2007). Stage-based soft-transition multiple PCA modeling and on-line monitoring strategy for batch processes. Journal of Process Control, 17(9), 728–741.

Zhou, Q., Yan, P., Liu, H., & Xin, Y. (2017). A hybrid fault diagnosis method for mechanical components based on ontology and signal analysis. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-017-1351-1.

Zhou, Z., Wen, C., & Yang, C. (2015). Fault detection using random projections and k-nearest neighbor rule for semiconductor manufacturing processes. IEEE Transactions on Semiconductor Manufacturing, 28(1), 70–79.

Ziani, R., Felkaoui, A., & Zegadi, R. (2017). Bearing fault diagnosis using multiclass support vector machines with binary particle swarm optimization and regularized Fisher’s criterion. Journal of Intelligent Manufacturing, 28(2), 405–417.

Zsifkovits, M., Moll, M., Pham, T. S., & Pickl, S. W. (2017). A visual approach to data fusion in sensor networks. In Proceedings of international conference on security and management (pp. 3–6).

Acknowledgements

This work is partially supported by the National Natural Science Foundation of China (61503017, U1435220), the Aeronautical Science Foundation of China (2016ZC51022), the SURECAP CPER project and the Platform CAPSEC funded by Région Champagne-Ardenne and FEDER, the Fundamental Research Funds for the Central Universities (YWF-14-RSC-102).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, T., Qiao, M., Zhang, M. et al. Data-driven prognostic method based on self-supervised learning approaches for fault detection. J Intell Manuf 31, 1611–1619 (2020). https://doi.org/10.1007/s10845-018-1431-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-018-1431-x