Abstract

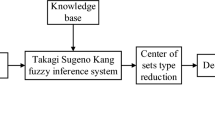

Due to the complexity of the high-pressure jet assisted turning, knowledge, and prediction of the cutting forces are essential for the planning of machining operations for maximum productivity and quality. However, it is well known that during processing using this procedure there are difficulties in collecting data. It is required to establish an adequate model that would make it possible to predict the cutting force based on the input parameters. During machining to avoid difficulties in acquisition data, two models have developed based on fuzzy logic that will allow indirect monitoring of the cutting force. This research uses the improved fuzzy logic methods for modeling, whereby it can make predictions of the main cutting force according to the different input parameters. The contribution of this work reflected through the application of two innovative methods based on reducing the number of rules, which leads to better interpretability of models. First is the Mamdani with rule reduction method, and second is the Sugeno sub-clustering method based on the identification of the model structure, it comes down to finding the required number of rules by forming specific clusters. Both approaches differ by reducing the number of rules without affecting the accuracy of the models. The ability to predict the model determined by applying different statistical parameters. It concluded that Mamdani and Sugeno models give an approximate quality of the prediction. The resulting models also have an acceptable error to predict data that did not participate in their creation. Furthermore, obtained models can be used at the generalization stage where the cutting force information is required and where direct measurement is not possible.

Similar content being viewed by others

Abbreviations

- D n :

-

Diameter of the nozzle

- d :

-

Distance between the impact point of the jet and the cutting edge

- P :

-

Pressure of the jet

- v c :

-

Cutting speed

- f :

-

Feed rate

- F c :

-

Main cutting force

- F x :

-

Axial cutting force

- F y :

-

Radial cutting force

- F z :

-

Tangential cutting force

- HPJAT:

-

High-pressure jet assisted turning

- MISO:

-

Multi-input–single-output

- MIMO:

-

Multi-input–multi-output

- ANOVA:

-

Analysis of variance

- MF:

-

Membership function

- x :

-

Axis x of input variable

- \( \upsigma \) :

-

Standard deviation

- c :

-

Mean value (center)

- MV :

-

Measured values

- PV :

-

Predicted values

- R 2 :

-

Coefficient of determination

- MSE :

-

Mean square error

- MAE :

-

Mean absolute error

- FL:

-

Fuzzy logic with rule reduction

- SC:

-

Sub-clustering

References

Aydın, M., Karakuzu, C., Uçar, M., Cengiz, A., & Çavuşlu, M. A. (2013). Prediction of surface roughness and cutting zone temperature in dry turning processes of AISI304 stainless steel using ANFIS with PSO learning. The International Journal of Advanced Manufacturing Technology, 67(1–4), 957–967. https://doi.org/10.1007/s00170-012-4540-2.

Ayed, Y., Robert, C., Germain, G., & Ammar, A. (2016). Development of a numerical model for the understanding of the chip formation in high-pressure water-jet assisted machining. Finite Elements in Analysis and Design, 108, 1–8. https://doi.org/10.1016/j.finel.2015.09.003.

Barzani, M. M., Zalnezhad, E., Sarhan, A. A., Farahany, S., & Ramesh, S. (2015). Fuzzy logic based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement, 61, 150–161. https://doi.org/10.1016/j.measurement.2014.10.003.

Bland, J. M., & Altman, D. G. (1999). Measuring agreement in method comparison studies. Statistical Methods in Medical Research, 8(2), 135–160. https://doi.org/10.1177/096228029900800204.

Boukezzi, L., Bessissa, L., Boubakeur, A., & Mahi, D. (2017). Neural networks and fuzzy logic approaches to predict mechanical properties of XLPE insulation cables under thermal aging. Neural Computing and Applications, 28(11), 3557–3570. https://doi.org/10.1007/s00521-016-2259-y.

Chiu, S. L. (1994). Fuzzy model identification based on cluster estimation. Journal of Intelligent & fuzzy systems, 2(3), 267–278. https://doi.org/10.3233/IFS-1994-2306.

Choudhury, I., & El-Baradie, M. (1998). Machinability of nickel-base super alloys: A general review. Journal of Materials Processing Technology, 77(1), 278–284. https://doi.org/10.1016/S0924-0136(97)00429-9.

Çolak, O. (2012). Investigation on machining performance of Inconel 718 in high pressure cooling conditions. Strojniški vestnik-Journal of Mechanical Engineering, 58(11), 683–690. https://doi.org/10.5545/sv-jme.2012.730.

Crafoord, R., Kaminski, J., Lagerberg, S., Ljungkrona, O., & Wretland, A. (1999). Chip control in tube turning using a high-pressure water jet. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 213(8), 761–767. https://doi.org/10.1243/0954405991517191.

Ezugwu, E. O. (2005). Key improvements in the machining of difficult-to-cut aerospace superalloys. International Journal of Machine Tools and Manufacture, 45(12–13), 1353–1367. https://doi.org/10.1016/j.ijmachtools.2005.02.003.

Ezugwu, E., Da Silva, R., Bonney, J., & Machado, A. (2005). Evaluation of the performance of CBN tools when turning Ti–6Al–4V alloy with high pressure coolant supplies. International Journal of Machine Tools and Manufacture, 45(9), 1009–1014. https://doi.org/10.1016/j.ijmachtools.2004.11.027.

González Rodríguez, G., Gonzalez-Cava, J. M., & Méndez Pérez, J. A. (2019). An intelligent decision support system for production planning based on machine learning. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-019-01510-y.

Jagadish, B., Bhowmik, S., & Ray, A. (2019). Prediction of surface roughness quality of green abrasive water jet machining: A soft computing approach. Journal of Intelligent Manufacturing, 30(8), 2965–2979. https://doi.org/10.1007/s10845-015-1169-7.

Jain, V., & Raj, T. (2017). Tool life management of unmanned production system based on surface roughness by ANFIS. International Journal of System Assurance Engineering and Management, 8(2), 458–467. https://doi.org/10.1007/s13198-016-0450-2.

Kaminski, J., & Alvelid, B. (2000). Temperature reduction in the cutting zone in water-jet assisted turning. Journal of Materials Processing Technology, 106(1–3), 68–73. https://doi.org/10.1016/S0924-0136(00)00640-3.

Karabulut, Ş. (2015). Optimization of surface roughness and cutting force during AA7039/Al2O3 metal matrix composites milling using neural networks and Taguchi method. Measurement, 66, 139–149. https://doi.org/10.1016/j.measurement.2015.01.027.

Khaniyev, T., Gökpınar, F., Hanalioglu, T., & Turksen, I. B. (2018). On the stationary distribution for a fuzzy inventory model of type (s, S) with inverse Gaussian distributed demands. Iranian Journal of Science and Technology, Transactions A: Science. https://doi.org/10.1007/s40995-017-0363-1.

Khorasani, A., & Yazdi, M. R. S. (2017). Development of a dynamic surface roughness monitoring system based on artificial neural networks (ANN) in milling operation. The International Journal of Advanced Manufacturing Technology, 93(1–4), 141–151. https://doi.org/10.1007/s00170-015-7922-4.

Kim, D.-H., & Lee, C.-M. (2014). A study of cutting force and preheating-temperature prediction for laser-assisted milling of Inconel 718 and AISI 1045 steel. International Journal of Heat and Mass Transfer, 71, 264–274. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.021.

Klir, G. J., & Folger, T. A. (1987). Fuzzy sets, uncertainty, and information. Upper Saddle River, NY: Prentice-Hall, Inc.

Kovac, P., Rodic, D., Pucovsky, V., Savkovic, B., & Gostimirovic, M. (2012). Application of fuzzy logic and regression analysis for modeling surface roughness in face milliing. Journal of Intelligent Manufacturing, 24(4), 755–762. https://doi.org/10.1007/s10845-012-0623-z.

Kovac, P., Rodic, D., Pucovsky, V., Savkovic, B., & Gostimirovic, M. (2014). Multi-output fuzzy inference system for modeling cutting temperature and tool life in face milling. Journal of Mechanical Science and Technology, 28(10), 4247–4256. https://doi.org/10.1007/s12206-014-0938-0.

Kuram, E., & Ozcelik, B. (2016). Micro-milling performance of AISI 304 stainless steel using Taguchi method and fuzzy logic modelling. Journal of Intelligent Manufacturing, 27(4), 817–830. https://doi.org/10.1007/s10845-014-0916-5.

Lee, T. H. (2011). Development of a theoretical model to predict cutting forces for hard machining. International Journal of Precision Engineering and Manufacturing, 12(5), 775–782. https://doi.org/10.1007/s12541-011-0103-y.

Maher, I., Eltaib, M., Sarhan, A. A., & El-Zahry, R. (2014). Investigation of the effect of machining parameters on the surface quality of machined brass (60/40) in CNC end milling—ANFIS modeling. The International Journal of Advanced Manufacturing Technology, 74(1–4), 531–537. https://doi.org/10.1007/s00170-014-6016-z.

Majumder, A. (2013). Process parameter optimization during EDM of AISI 316 LN stainless steel by using fuzzy based multi-objective PSO. Journal of Mechanical Science and Technology, 27(7), 2143–2151. https://doi.org/10.1007/s12206-013-0524-x.

Maroju, N. K., & Pasam, V. K. (2019). FE modeling and experimental analysis of residual stresses in vibration assisted turning of Ti6Al4V. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-019-00021-3.

McParland, D., Baron, S., O’Rourke, S., Dowling, D., Ahearne, E., & Parnell, A. (2019). Prediction of tool-wear in turning of medical grade cobalt chromium molybdenum alloy (ASTM F75) using non-parametric Bayesian models. Journal of Intelligent Manufacturing, 30(3), 1259–1270. https://doi.org/10.1007/s10845-017-1317-3.

Moore, D. S., Notz, W., & Fligner, M. A. (2013). The basic practice of statistics. San Francisco: W.H. Freeman.

Nain, S. S., Sihag, P., & Luthra, S. (2018). Performance evaluation of fuzzy-logic and BP-ANN methods for WEDM of aeronautics super alloy. MethodsX, 5, 890–908. https://doi.org/10.1016/j.mex.2018.04.006.

Nandy, A., Gowrishankar, M., & Paul, S. (2009). Some studies on high-pressure cooling in turning of Ti–6Al–4V. International Journal of Machine Tools and Manufacture, 49(2), 182–198. https://doi.org/10.1016/j.ijmachtools.2008.08.008.

Nukman, Y., Hassan, M., & Harizam, M. (2013). Optimization of prediction error in CO2 laser cutting process by Taguchi artificial neural network hybrid with genetic algorithm. Applied Mathematics & Information Sciences, 7(1), 363–370. https://doi.org/10.12785/amis/070145.

Obikawa, T., Yamaguchi, M., Funai, K., Kamata, Y., & Yamada, S. (2012). Air jet assisted machining of nickel-base superalloy. International Journal of Machine Tools and Manufacture, 61, 20–26. https://doi.org/10.1016/j.ijmachtools.2012.05.005.

Paul, S. K. (2015). Supplier selection for managing supply risks in supply chain: A fuzzy approach. The International Journal of Advanced Manufacturing Technology, 79(1–4), 657–664. https://doi.org/10.1007/s00170-015-6867-y.

Pimenov, D. Y., Bustillo, A., & Mikolajczyk, T. (2018). Artificial intelligence for automatic prediction of required surface roughness by monitoring wear on face mill teeth. Journal of Intelligent Manufacturing, 29(5), 1045–1061. https://doi.org/10.1007/s10845-017-1381-8.

Ren, Q., Balazinski, M., Jemielniak, K., Baron, L., & Achiche, S. (2013). Experimental and fuzzy modelling analysis on dynamic cutting force in micro milling. Soft Computing, 17(9), 1687–1697. https://doi.org/10.1007/s00500-013-0983-0.

Sahali, M., Belaidi, I., & Serra, R. (2016). New approach for robust multi-objective optimization of turning parameters using probabilistic genetic algorithm. The International Journal of Advanced Manufacturing Technology, 83(5–8), 1265–1279. https://doi.org/10.1007/s00170-015-7526-z.

Salimiasl, A., & Özdemir, A. (2016). Analyzing the performance of artificial neural network (ANN)-, fuzzy logic (FL)-, and least square (LS)-based models for online tool condition monitoring. The International Journal of Advanced Manufacturing Technology, 87(1–4), 1145–1158. https://doi.org/10.1007/s00170-016-8548-x.

Setnes, M. (2003). Simplification and reduction of fuzzy rules. In J. Casillas, O. Cordón, F. Herrera, & L. Magdalena (Eds.), Interpretability issues in fuzzy modeling (pp. 278–302). Berlin: Springer.

Sharma, V. S., Dogra, M., & Suri, N. (2009). Cooling techniques for improved productivity in turning. International Journal of Machine Tools and Manufacture, 49(6), 435–453. https://doi.org/10.1016/j.ijmachtools.2008.12.010.

Singh, B., Roy, H., Mondal, B., Roy, S., & Mandal, N. (2019). Measurement of chip morphology and multi criteria optimization of turning parameters for machining of AISI 4340 steel using Y-ZTA cutting insert. Measurement, 142, 181–194. https://doi.org/10.1016/j.measurement.2019.04.064.

Sugeno, M., & Kang, G. (1988). Structure identification of fuzzy model. Fuzzy Sets and Systems, 28(1), 15–33. https://doi.org/10.1016/0165-0114(88)90113-3.

Taniguchi, T., Tanaka, K., Ohtake, H., & Wang, H. O. (2001). Model construction, rule reduction, and robust compensation for generalized form of Takagi–Sugeno fuzzy systems. IEEE Transactions on Fuzzy Systems, 9(4), 525–538. https://doi.org/10.1109/91.940966.

Thanedar, A., Dongre, G. G., & Joshi, S. S. (2019). Analytical modelling of temperature in cylindrical grinding to predict grinding burns. International Journal of Precision Engineering and Manufacturing, 20(1), 13–25. https://doi.org/10.1007/s12541-019-00037-9.

Unune, D. R., Barzani, M. M., Mohite, S. S., & Mali, H. S. (2018). Fuzzy logic-based model for predicting material removal rate and average surface roughness of machined Nimonic 80A using abrasive-mixed electro-discharge diamond surface grinding. Neural Computing and Applications, 29(9), 647–662. https://doi.org/10.1007/s00521-016-2581-4.

Willmott, C. J. (1981). On the validation of models. Physical Geography, 2(2), 184–194. https://doi.org/10.1080/02723646.1981.10642213.

Yager, R. R., & Filev, D. P. (1994). Essentials of fuzzy modeling and control. New Jersey: Wiley.

Yilmaz, O., Eyercioglu, O., & Gindy, N. N. (2006). A user-friendly fuzzy-based system for the selection of electro discharge machining process parameters. Journal of Materials Processing Technology, 172(3), 363–371. https://doi.org/10.1016/j.jmatprotec.2005.09.023.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8(3), 338–353. https://doi.org/10.1016/S0019-9958(65)90241-X.

Zerti, A., Yallese, M. A., Meddour, I., Belhadi, S., Haddad, A., & Mabrouki, T. (2019). Modeling and multi-objective optimization for minimizing surface roughness, cutting force, and power, and maximizing productivity for tempered stainless steel AISI 420 in turning operations. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-018-2984-8.

Acknowledgements

This study was supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia, Project TR 35015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rodić, D., Sekulić, M., Gostimirović, M. et al. Fuzzy logic and sub-clustering approaches to predict main cutting force in high-pressure jet assisted turning. J Intell Manuf 32, 21–36 (2021). https://doi.org/10.1007/s10845-020-01555-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-020-01555-4