Abstract

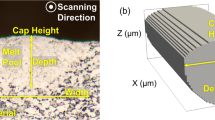

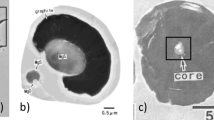

The microstructure of nodular cast irons is characterized by the presence of spheroidal graphite nodules. Metallographic tests may show irregular or degenerated graphite nodules that indicate a reduction in tensile strength of the material as well as its yield limit. This work proposes a computer vision algorithm to estimate the amount of degenerated graphite nodules as well as image analysis necessary to determine the relationship between this quantity of degenerated nodules and the loss of mechanical properties of the nodular cast iron. The proposed algorithm was tested using two cast iron samples, by measuring their microhardness and tensile strength. The results show that the amount of degenerated graphite nodules is inversely proportional to the limit of traction resistance. Sample “A”, of the two samples tested, presented more degenerated nodules than “B” and a lower limit of traction resistance; therefore, it needs less strength to break.

Similar content being viewed by others

References

Adams R, Bischof L (1994) Seeded region growing. IEEE Trans Pattern Anal Mach Intell 16(6):641–647

Afshari E, Ghambari M (2018) Predicting breakage behavior and particle size of bronze and cast iron machining chips pulverized by jet milling. Adv Powder Technol 29(9):2153–2160. https://doi.org/10.1016/j.apt.2018.05.023. http://www.sciencedirect.com/science/article/pii/S0921883118302474

Alabeedi KF, Abboud JH, Benyounis KY (2009) Microstructure and erosion resistance enhancement of nodular cast iron by laser melting. Wear 266(9):925–933

Al-Bukhaiti MA, Mohamad AAK, Emara KM, Ahmed SM (2018) Effect of slurry concentration on erosion wear behavior of AISI 5117 steel and high-chromium white cast iron. Ind Lubr Tribol 70(4):628–638. https://doi.org/10.1108/ILT-07-2016-0151

Benyounis K, Fakron OMA, Abboud JH, Olabi AG, Hashmi MJS (2005) Surface melting of nodular cast iron by Nd-YAG laser and TIG. J Mater Process Technol 170(1):127–132

Callister WD, Rethwisch DG (2011) Materials science and engineering, vol 5. Wiley, New York

Clement P, Angeli JP, Pineau A (1984) Short crack behaviour in nodular cast iron. Fatigue Fract Eng Mater Struct 7(4):251–265

da Candido GVM, de Melo TAA, De Albuquerque VHC, Gomes RM, de Lima SJG, Tavares JMRS (2012) Characterization of a CuAlBe alloy with different Cr contents. J Mater Eng Perform 21(11):2398–2406. https://doi.org/10.1007/s11665-012-0159-6

da Cruz MAA, Rodrigues JJPC, Al-Muhtadi J, Korotaev VV, de Albuquerque VHC (2018) A reference model for internet of things middleware. IEEE Internet Things J 5(2):871–883. https://doi.org/10.1109/JIOT.2018.2796561

Da Nobrega JA, Diniz DDS, Silva AA, Maciel TM, de Albuquerque VHC, Tavares JMRS (2016) Numerical evaluation of temperature field and residual stresses in an API 5L X80 steel welded joint using the finite element method. Metals 6(2):28. https://doi.org/10.3390/met6020028. http://www.mdpi.com/2075-4701/6/2/28

de Albuquerque VHC, de Alexandria AR, Cortez PC, Tavares JMR (2009) Evaluation of multilayer perceptron and self-organizing map neural network topologies applied on microstructure segmentation from metallographic images. NDT & E Int 42(7):644–651. https://doi.org/10.1016/j.ndteint.2009.05.002. http://www.sciencedirect.com/science/article/pii/S0963869509000899

de Albuquerque VHC, de Macedo Silva E, Leite JP, de Moura EP, de Arajo Freitas VL, Tavares JMR (2010) Spinodal decomposition mechanism study on the duplex stainless steel UNS s31803 using ultrasonic speed measurements. Mater Des 31(4):2147–2150. https://doi.org/10.1016/j.matdes.2009.11.010. http://www.sciencedirect.com/science/article/pii/S0261306909006293. (Design of nanomaterials and nanostructures)

de Albuquerque VHC, de Melo TAA, de Oliveira DF, Gomes RM, Tavares JMR (2010) Evaluation of grain refiners influence on the mechanical properties in a cualbe shape memory alloy by ultrasonic and mechanical tensile testing. Mater Des 31(7):3275–3281. https://doi.org/10.1016/j.matdes.2010.02.010. http://www.sciencedirect.com/science/article/pii/S026130691000083X

de Albuquerque VHC, Silva CC, Normando PG, Moura EP, Tavares JMR (2012) Thermal aging effects on the microstructure of nb-bearing nickel based superalloy weld overlays using ultrasound techniques. Mater Des (1980–2015) 36:337–347. https://doi.org/10.1016/j.matdes.2011.11.035. http://www.sciencedirect.com/science/article/pii/S0261306911007953. (Sustainable materials, design and applications)

de Albuquerque VHC, Cortez PC, Alexandria AR, Aguiar WM, Silva EM (2007) Sistema de segmentação de imagens para quantificação de microestruturas em metais utilizando redes neurais artificiais. Revista Matéria 12(2):394–407

de Albuquerque VHC, Cortez PC, de Alexandria AR, Tavares JMR (2008) A new solution for automatic microstructures analysis from images based on a backpropagation artificial neural network. Nondestruct Test Eval 23(4):273–283. https://doi.org/10.1080/10589750802258986

de Albuquerque VHC, Filho PR, Cavalcante TS, Tavares JMR (2010) New computational solution to quantify synthetic material porosity from optical microscopic images. J Microsc 240(1):50–59

de Albuquerque VHC, Tavares JMRS, Duro LM (2010) Evaluation of delamination damage on composite plates using an artificial neural network for the radiographic image analysis. J Compos Mater 44(9):1139–1159. https://doi.org/10.1177/0021998309351244

de Albuquerque VHC, Silva CC, Menezes TIdS, Farias JP, Tavares JMR (2011) Automatic evaluation of nickel alloy secondary phases from SEM images. Microsc Res Tech 74(1):36–46

de Albuquerque V, Barbosa C, Silva C, Moura E, Filho P, Papa J, Tavares J (2015) Ultrasonic sensor signals and optimum path forest classifier for the microstructural characterization of thermally-aged inconel 625 alloy. Sensors 15(6):12474. https://doi.org/10.3390/s150612474

de Araújo Freitas VL, de Albuquerque VHC, de Macedo Silva E, Silva AA, Tavares JMR (2010) Nondestructive characterization of microstructures and determination of elastic properties in plain carbon steel using ultrasonic measurements. Mater Sci Eng A 527(16):4431–4437. https://doi.org/10.1016/j.msea.2010.03.090. http://www.sciencedirect.com/science/article/pii/S0921509310003771

de Araújo Freitas VL, Normando PG, de Albuquerque VHC, de MacedoSilva E, Silva AA, Tavares JMRS (2011) Nondestructive characterization and evaluation of embrittlement kinetics and elastic constants of duplex stainless steel SAF 2205 for different aging times at 425\(^{\circ }\)c and 475\(^{\circ }\)c. J Nondestruct Eval 30(3):130–136. https://doi.org/10.1007/s10921-011-0100-1

de Macedo Silva E, Leite JP, de França Neto FA, Leite JP, Fialho WM, de Albuquerque VHC, Tavares JMR (2014) Evaluation of the magnetic permeability for the microstructural characterization of a duplex stainless steel. J Test Eval 44(3):1106–1111

de Macedo Silva E, Leite JP, Leite JP, Fialho WML, de Albuquerque VHC, Tavares JMRS (2016) Induced magnetic field used to detect the sigma phase of a 2205 duplex stainless steel. J Nondestruct Eval 35(2):28. https://doi.org/10.1007/s10921-016-0339-7

de Macedo Silva E, de Albuquerque VHC, Leite JP, Varela ACG, de Moura EP, Tavares JMR (2009) Phase transformations evaluation on a UNS s31803 duplex stainless steel based on nondestructive testing. Mater Sci Eng A 516(1):126–130. https://doi.org/10.1016/j.msea.2009.03.004. http://www.sciencedirect.com/science/article/pii/S0921509309003293

de Silva PMO, de Abreu HFG, de Albuquerque VHC, de Lima Neto P, Tavares JMR (2011) Cold deformation effect on the microstructures and mechanical properties of AISI 301LN and 316L stainless steels. Mater Des 32(2):605–614. https://doi.org/10.1016/j.matdes.2010.08.012. http://www.sciencedirect.com/science/article/pii/S0261306910004875

de Albuquerque VHC, de Melo TAA, Gomes RM, de Lima SJG, Tavares JMR (2010) Grain size and temperature influence on the toughness of a cualbe shape memory alloy. Mater Sci Eng A 528(1):459–466. https://doi.org/10.1016/j.msea.2010.09.034. http://www.sciencedirect.com/science/article/pii/S0921509310010646. (Special topic section: local and near surface structure from diffraction)

DeCost BL, Francis T, Holm EA (2018) High throughput quantitative metallography for complex microstructures using deep learning: a case study in ultrahigh carbon steel. arXiv preprint arXiv:1805.08693

Duro LMP, Tavares JMR, de Albuquerque VHC, Gonalves DJ (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct 96:576–583. https://doi.org/10.1016/j.compstruct.2012.08.003. http://www.sciencedirect.com/science/article/pii/S0263822312003674

Gupta G (2011) Algorithm for image processing using improved median filter and comparison of mean, median and improved median filter. Int J Soft Comput Eng (IJSCE) 1(5):304–311

Jailin C, Bouterf A, Poncelet M, Roux S (2017) In situ\(\mu \) ct-scan mechanical tests: fast 4d mechanical identification. Exp Mech 57(8):1327–1340

Lakshmanaprabu SK, Shankar K, Khanna A, Gupta D, Rodrigues JJPC, Pinheiro PR, Albuquerque VHCD (2018) Effective features to classify big data using social internet of things. IEEE Access 6:24196–24204. https://doi.org/10.1109/ACCESS.2018.2830651

Lal R, Singh RC (2018) Experimental comparative study of chrome steel pin with and without chrome plated cast iron disc in situ fully flooded interface lubrication. Surf Topogr Metrol Prop 6(3):035,001. http://stacks.iop.org/2051-672X/6/i=3/a=035001. Accessed 20 May 2018

Mahmoud MME, Rodrigues JJPC, Ahmed SH, Shah SC, Al-Muhtadi JF, Korotaev VV, Albuquerque VHCD (2018) Enabling technologies on cloud of things for smart healthcare. IEEE Access 6:31950–31967. https://doi.org/10.1109/ACCESS.2018.2845399

Nadot Y, Mendez J, Ranganathan N, Beranger AS (1999) Fatigue life assessment of nodular cast iron containing casting defects. Fatigue Fract Eng Mater Struct (UK) 22(4):289–300

Nunes TM, de Albuquerque VHC, Papa JP, Silva CC, Normando PG, Moura EP, Tavares JMR (2013) Automatic microstructural characterization and classification using artificial intelligence techniques on ultrasound signals. Expert Syst Appl 40(8):3096–3105. https://doi.org/10.1016/j.eswa.2012.12.025. http://www.sciencedirect.com/science/article/pii/S0957417412012663

Ochi Y, Masaki K, Matsumura T, Sekino T (2001) Effect of shot-peening treatment on high cycle fatigue property of ductile cast iron. Int J Fatigue 23(5):441–448

Otsu N (1979) A threshold selection method from gray-level histograms. IEEE Trans Syst Man Cybern 9(1):62–66

Papa JP, Nakamura RY, de Albuquerque VHC, Falco AX, Tavares JMR (2013) Computer techniques towards the automatic characterization of graphite particles in metallographic images of industrial materials. Expert Syst Appl 40(2):590–597. https://doi.org/10.1016/j.eswa.2012.07.062. http://www.sciencedirect.com/science/article/pii/S0957417412009189

Papa JP, Nakamura RYM, de Albuquerque VHC, Falcão AX, Tavares JMRS (2013) Computer techniques towards the automatic characterization of graphite particles in metallographic images of industrial materials. Expert Syst Appl 40(2):590–597. https://doi.org/10.1016/j.eswa.2012.07.062

Peixoto FdM, Rebouças EdS, Xavier FGdL, Rebouças Filho PP (2015) Software development for ductile cast iron graphite nodules density calculation using digital image processing. Matéria (Rio de Janeiro) 20(1):262–272

Rebouas Filho PP, da Silveira Cavalcante T, de Albuquerque VHC, Tavares JMR (2009) Brinell and vickers hardness measurement using image processing and analysis techniques. J Test Eval 38(1):88–94

Rodrigues JJPC, Segundo DBDR, Junqueira HA, Sabino MH, Prince RM, Al-Muhtadi J, Albuquerque VHCD (2018) Enabling technologies for the internet of health things. IEEE Access 6:13129–13141. https://doi.org/10.1109/ACCESS.2017.2789329

Silva E, Marinho L, Filho P, Leite J, Leite J, Fialho W, de Albuquerque V, Tavares J (2016) Classification of induced magnetic field signals for the microstructural characterization of sigma phase in duplex stainless steels. Metals 6(7):164. https://doi.org/10.3390/met6070164

Silva E, Paula A, Leite J, Leite J, Andrade L, de Albuquerque V, Tavares J (2016) Detection of the magnetic easy direction in steels using induced magnetic fields. Metals 6(12):317. https://doi.org/10.3390/met6120317

Silva CC, de Albuquerque VHC, Miná EM, Moura EP, Tavares JMRS (2018) Mechanical properties and microstructural characterization of aged nickel-based alloy 625 weld metal. Metall Mater Trans A 49(5):1653–1673. https://doi.org/10.1007/s11661-018-4526-2

Silva A, Juc S, Costa L, Silva P, Pereira R (2018) Versatile IoT system for cloud-based sensor monitoring. J Mechatron Eng 1(1):2–10. https://doi.org/10.1234/jme.v1i1.8. http://jme.ojs.galoa.net.br/index.php/jme/article/view/8

Taheri S, Vedienbaum A, Nicolau A, Hu N, Haghighat MR (2018) Opencv.js: Computer Vision processing for the open web platform. In: Proceedings of the 9th ACM Multimedia Systems Conference, MMSys ’18. ACM, New York, pp 478–483. https://doi.org/10.1145/3204949.3208126

Acknowledgements

VHCA acknowledges the sponsorship from the Brazilian National Council for Research and Development (CNPq) via Grant No. 304315/2017-6. ARA thanks the National Council for Scientific and Technological Development (CNPq, Grant #447477/2014-5, #488420/2013-0 and #304790/2015-0), in Brazil. The authors also thank Francisco Alan Xavier Mota.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pereira, R.F., da Silva Filho, V.E.R., Moura, L.B. et al. Automatic quantification of spheroidal graphite nodules using computer vision techniques. J Supercomput 76, 1212–1225 (2020). https://doi.org/10.1007/s11227-018-2579-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11227-018-2579-z