Abstract

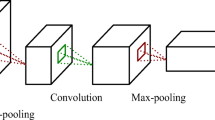

Timely and accurate bearing fault detection and diagnosis is important for reliable and safe operation of industrial systems. In this study, performance of a generic real-time induction bearing fault diagnosis system employing compact adaptive 1D Convolutional Neural Network (CNN) classifier is extensively studied. In the literature, although many studies have developed highly accurate algorithms for detecting bearing faults, their results have generally been limited to relatively small train/test data sets. As opposed to conventional intelligent fault diagnosis systems that usually encapsulate feature extraction, feature selection and classification as distinct blocks, the proposed system takes directly raw time-series sensor data as input and it can efficiently learn optimal features with the proper training. The main advantages of the 1D CNN based approach are 1) its compact architecture configuration (rather than the complex deep architectures) which performs only 1D convolutions making it suitable for real-time fault detection and monitoring, 2) its cost effective and practical real-time hardware implementation, 3) its ability to work without any pre-determined transformation (such as FFT or DWT), hand-crafted feature extraction and feature selection, and 4) its capability to provide efficient training of the classifier with limited size of training data set and limited number of BP iterations. Effectiveness and feasibility of the 1D CNN based fault diagnosis method is validated by applying it to two commonly used benchmark real vibration data sets and comparing the results with the other competing intelligent fault diagnosis methods.

Similar content being viewed by others

References

Gao, Z., Cecati, C., & Ding, S. X. (2015). A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Transactions Industrial Electronics, 62, 3757–3767.

Filippetti, F., Bellini, A., & Capolino, G. A. (2013). Condition monitoring and diagnosis of rotor faults in induction machines: State of art and future perspectives. In Proceedings of the IEEE WEMDCD, Paris, pp 196–209.

Zhou, W., Habetler, T., & Harley, R. (2008). Bearing fault detection via stator current noise cancellation and statistical control. IEEE Transactions on Industrial Electronics, 55, 4260–4269.

Kral, C., Habetler, T. G., & Harley, R. G. (2004). Detection of mechanical imbalances of induction machines without spectral analysis of time domain signals. IEEE Transactions on Industry Applications, 40, 1101–1106.

Schoen, R. R., Habetler, T. G., Kamran, F., & Bartheld, R. G. (1995). Motor bearing damage detection using stator current monitoring. IEEE Transactions on Industry Applications, 31, 1274–1279.

Kliman, G. B., Premerlani, W. J., Yazici, B., Koegl, R. A., & Mazereeuw, J. (1997). Sensorless online motor diagnostics. IEEE Computer Applications in Power, 10, 39–43.

Pons-Llinares, J., Antonino-Daviu, J. A., Riera-Guasp, M., Lee, S. B., Kang, T. J., & Yang, C. (2015). Advanced inductionmotor rotorfault diagnosis via continuous and discrete time–frequency tools. IEEE Transactions on Industrial Electronics, 62, 1791–1802.

Li, D. Z., Wang, W., & Ismail, F. (2015). An enhanced bispectrum technique with auxiliary frequency injection for induction motor health condition monitoring. IEEE Transactions on Instrumentation and Measurement, 67, 2279–2287.

Eren, L., & Devaney, M. J. (2004). Bearing damage detection via wavelet packet decomposition of the stator current. IEEE Transactions on Instrumentation and Measurement, 53, 431–436.

Yan, R., Gao, R. X., & Chen, X. (2014). Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Processing, 96, 1–15.

Li, B., Chow, M.-Y., Tipsuwan, Y., & Hung, J. C. (2000). Neural network based motor rolling bearing fault diagnosis. IEEE Transactions on Industrial Electronics, 47, 1060–1069.

Bin, G. F., Gao, J. J., Li, X. J., & Dhillon, B. S. (2012). Early fault diagnosis of rotating machinery based on wavelet packets – Empirical mode decomposition feature extraction and neural network. Mechanical Systems and Signal Processing, 27, 696–711.

Tung, V. T., Yang, B.-S., Oh, M.-S., & Tan, A. C. C. (2009). Fault diagnosis of induction motor based on decision trees and adaptive neurofuzzy inference. Expert Systems with Applications, 36, 1840–1849.

Wu, S.-D., Wu, P.-H., Wu, C.-W., Ding, J.-J., & Wang, C.-C. (2012). Bearing fault diagnosis based on multiscale permutation entropy and support vector machine. Entropy, 14, 1343–1356.

Kang, M., Kim, J., Kim, J.-M., Tan, A. C. C., Kim, E. Y., & Choi, B.-K. (2014). Reliable fault diagnosis for lowspeed bearings using individually trained support vector machines with kernel discriminative feature analysis. IEEE Transactions on Power Electronics, 30, 2786–2797.

Kowalski, C. T., & Kowalska, T. O. (2003). Neural network application for induction motor faults diagnosis. Mathematics and Computers in Simulation, 63, 435–448.

Ballal, M. S., Khan, Z. J., Suryawanshi, H. M., & Sonolikar, R. L. (2007). Adaptive neural fuzzy inference system for the detection of inter-turn insulation and bearing wear faults in induction motor. IEEE Transactions on Industrial Electronics, 54, 250–258.

Kim, K., & Parlos, A. G. (2002). Induction motor fault diagnosis based on neuropredictors and wavelet signal processing. IEEE/ ASME Transactions on Mechatronics, 7, 201–219.

Van, M., & Kang, H.-J. (2016). Bearing defect classification based on individual wavelet local fisher discriminant analysis with particle swarm optimization. IEEE Transactions on Industrial Informatics, 12, 124–135.

Liu, R., Yang, B., Zhang, X., Wang, S., & Chen, X. (2016). Time-frequency atoms-driven support vector machine method for bearings incipient fault diagnosis. Mechanical Systems and Signal Processing, 75, 345–370.

Dai, X., & Gao, Z. (2013). From model, signal to knowledge: A data-driven perspective of fault detection and diagnosis. IEEE Transactions on Industrial Informatics, 9, 2226–2238.

Qiao, H., Zhengjia, H., Zhousuo, Z., & Yanyang, Z. (2007). Fault diagnosis of rotating machinery based on improved wavelet package transform and SVMs ensemble. Mechanical Systems and Signal Processing, 21, 688–705.

Yaqub, M. F., Gondal, I., & Kamruzzaman, J. (2012). Inchoate fault detection framework: Adaptive selection of wavelet nodes and cumulant orders. IEEE Transactions on Instrumentation and Measurement, 61, 685–695.

Konar, P., & Chattopadhyay, P. (2011). Bearing fault detection of induction motor using wavelet and support vector machines (SVMs). Applied Soft Computing, 11, 4203–4211.

Wang, X., Zheng, Y., Zhao, Z., & Wang, J. (2015). Bearing fault diagnosis based on statistical locally, linear embedding. Sensors, 15, 16225–16247.

Shuai, J., Shen, C., & Zhu, Z. (2017). Adaptive morphological feature extraction and support vector regressive classification for bearing fault diagnosis. International Journal of Rotating Machinery, 2017, 1–10.

Vakharia, V., Gupta, V. K., & Kankar, P. K. (2014). A multiscale permutation entropy based approach to select wavelet for fault diagnosis of ball bearings. Journal of Vibration and Control, 21, 3123–3131.

Bellini, A., Filippetti, F., Franceshini, G., & Tassoni, C. (2001). Quantitative evaluation motor broken bars by means of electrical signature analysis. IEEE Transactions on Industry Applications, 37, 1248–1254.

Ayhan, B., Chow, M., & Song, M. (2005). Multiple signature processing-based fault detection schemes for broken rotor bar in induction motors. IEEE Transactions on Energy Conversion, 20, 336–343.

Ye, Z., Wu, B., & Sadeghian, A. (2003). Current signature analysis of induction motor mechanical faults by wavelet packet decomposition. IEEE Transactions on Industrial Electronics, 50, 1217–1227.

Wiesel, D. H., & Hubel, T. N. (1959). Receptive fields of single neurones in the cat’s striate cortex. The Journal of Physiology, 148, 574–591.

Kiranyaz, S., Ince, T., & Gabbouj, M. (2015). Real-time patient-specific ECG classification by 1D convolutional neural networks. IEEE Transactions on Biomedical Engineering, 63, 664–674.

Ince, T., Kiranyaz, S., Eren, L., Askar, M., & Gabbouj, M. (2016). Real-time motor fault detection by 1D convolutional neural networks. IEEE Transactions on Industrial Electronics, 63, 7067–7075.

Eren, L. (2017). Bearing Fault Detection by One-Dimensional Convolutional Neural Networks. Mathematical Problems in Engineering, 2017, 1–9.

Zhang, R., Peng, Z., Wu, L., Yao, B., & Guan, Y. (2017). Fault diagnosis from raw sensor data using deep neural networks considering temporal coherence. Sensors, 17, 549–565.

Ciresan, D. C., Meier, U., Gambardella, L. M., & Schmidhuber, J. (2010). Deep big simple neural nets for handwritten digit recognition. Neural Computation, 22, 3207–3220.

Scherer, D., Muller, A. & Behnke, S. (2010). Evaluation of pooling operations in convolutional architectures for object recognition. In Proceedings of the Int. Conf. on Artificial Neural Networks (ICANN), Thessaloniki, pp 92–101.

Krizhevsky, A., Sutskever, I., & Hinton, G. (2012). Imagenet classification with deep convolutional neural networks. In Proceedings of the Advances in Neural Information Processing Systems (NIPS), Lake Tahoe, pp 1097–1105.

Wowk, V. (1991). Machinery vibration, measurement and analysis. McGraw-Hill.

Lee, J., Qiu, H., Yu, G., & Lin, J. (2017). Rexnord technical services, IMS, University of Cincinnati. Bearing data set, NASA Ames prognostics data repository. NASA Ames Research Center: Moffett field. Available online: https://ti.arc.nasa.gov/tech/dash/pcoe/prognostic-data-repository/#bearing. Accessed 15 Mar 2017.

Case Western Reserve University Bearing Data Center Website. http://csegroups.case.edu/bearingdatacenter/home. Accessed 15 Mar 2017.

Qiu, H., Lee, J., Yu, G., & Lin, J. (2006). Wavelet filter-based weak signature detection method and its application on roller bearing prognostics. Journal of Sound and Vibration, 289, 1066–1090.

Randall, R. B. (2015). Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mechanical Systems and Signal Processing, 64-65, 100–131.

Farabet, C., Poulet, C., Han, J., & LeCun, Y. (2009). CNP: An FPGA-based processor for convolutional networks. In Proceedings of the International Conference on Field Programmable Logic and Applications, Prague, pp 32–37.

Acknowledgments

The authors would like to thank University of Cincinnati and Case Western Reserve University for making the bearing datasets publicly available and giving the permission to use it.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Eren, L., Ince, T. & Kiranyaz, S. A Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J Sign Process Syst 91, 179–189 (2019). https://doi.org/10.1007/s11265-018-1378-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11265-018-1378-3