Abstract

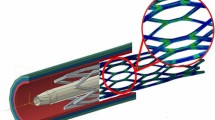

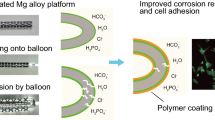

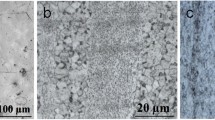

Magnesium stents are a promising candidate in the emerging field of absorbable metallic stents (AMSs). In this study, the mechanical and corrosion performance of dog-bone specimens and a specific stent design of a magnesium alloy, WE43, are assessed experimentally in terms of their corrosion behaviour and mechanical integrity. It is shown that plastic strains that are induced in the struts of the stent during stent deployment have a critical influence in directing subsequent corrosion behaviour within the material. In addition, the deployment and scaffolding characteristics of the magnesium stent are elucidated and contrasted with those of a commercial stainless steel stent. The magnesium stent is found to support higher levels of cyclic strain amplitude than the stainless steel stent, even prior to degradation, and this may play a role in reducing in-stent restenosis. This study provides new insights into the experimental performance of a current AMS design and material whilst demonstrating the critical influence of plastic strain on the corrosion performance and scaffolding ability of an AMS.

Similar content being viewed by others

References

Bowen PK, Gelbaugh JA, Mercier PJ et al (2012) Tensile testing as a novel method for quantitatively evaluating bioabsorbable material degradation. J Biomed Mater Res B Appl Biomater 100:2101–2113. doi:10.1002/jbm.b.32775

Bowen PK, Drelich J, Goldman J (2013) A new in vitro-in vivo correlation for bioabsorbable magnesium stents from mechanical behavior. Mater Sci Eng C Mater Biol Appl 33:5064–5070. doi:10.1016/j.msec.2013.08.042

Colombo A, Zahedmanesh H, Toner DM et al (2010) A method to develop mock arteries suitable for cell seeding and in vitro cell culture experiments. J Mech Behav Biomed Mater 3:470–477

Colombo A, Guha S, Mackle JN et al (2012) Cyclic strain amplitude dictates the growth response of vascular smooth muscle cells in vitro: role in in-stent restenosis and inhibition with a sirolimus drug-eluting stent. Biomech Model Mechanobiol 12:671–683. doi:10.1007/s10237-012-0433-4

Connolley T, McHugh PE, Bruzzi M (2005) A review of deformation and fatigue of metals at small size scales. Fatigue Fract Eng Mater Struct 28:1119–1152. doi:10.1111/j.1460-2695.2005.00951.x

Coy AE, Viejo F, Skeldon P, Thompson GE (2010) Susceptibility of rare-earth-magnesium alloys to micro-galvanic corrosion. Corros Sci 52:3896–3906. doi:10.1016/j.corsci.2010.08.006

Di Mario C, Griffiths H, Goktekin O et al (2004) Drug-eluting bioabsorbable magnesium stent. J Interv Cardiol 17:391–395. doi:10.1111/j.1540-8183.2004.04081.x

Draney MT, Herfkens RJ, Hughes TJR et al (2002) Quantification of vessel wall cyclic strain using cine phase contrast magnetic resonance imaging. Ann Biomed Eng 30:1033–1045. doi:10.1114/1.1513566

Erbel R, Di Mario C, Bartunek J et al (2007) Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: a prospective, non-randomised multicentre trial. Lancet 369:1869–1875. doi:10.1016/S0140-6736(07)60853-8

Galvin E, Morshed MM, Cummins C et al (2013) Surface modification of absorbable magnesium stents by reactive ion etching. J Plasma Chem Process 33:1137–1152. doi:10.1007/s11090-013-9477-1

Ge Q, Dellasega D, Demir GA, Vedani M (2013) The processing of ultrafine-grained Mg tubes for biodegradable stents. Acta Biomater. doi:10.1016/j.actbio.2013.01.010

Gray-Munro JE, Seguin C, Strong M (2009) Influence of surface modification on the in vitro corrosion rate of magnesium alloy AZ31. J Biomed Mater Res A 91:221–230. doi:10.1002/jbm.a.32205

Grogan JA, O’Brien BJ, Leen SB, McHugh PE (2011) A corrosion model for bioabsorbable metallic stents. Acta Biomater 7:3523–3533

Gu XN, Zhou WR, Zheng YF et al (2010) Corrosion fatigue behaviors of two biomedical Mg alloys—AZ91D and WE43—in simulated body fluid. Acta Biomater 6:4605–4613

Haude M, Erbel R, Erne P et al (2013) Safety and performance of the drug-eluting absorbable metal scaffold (DREAMS) in patients with de-novo coronary lesions: 12 month results of the prospective, multicentre, first-in-man BIOSOLVE-I trial. Lancet 381:836–844. doi:10.1016/S0140-6736(12)61765-6

Jain A, Duygulu O, Brown DW et al (2008) Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet. Mater Sci Eng A 486:545–555. doi:10.1016/j.msea.2007.09.069

Kalb H, Rzany A, Hensel B (2012) Impact of microgalvanic corrosion on the degradation morphology of WE43 and pure magnesium under exposure to simulated body fluid. Corros Sci 57:122–130. doi:10.1016/j.corsci.2011.12.026

Kannan MB, Dietzel W, Blawert C et al (2008) Stress corrosion cracking of rare-earth containing magnesium alloys ZE41, QE22 and Elektron 21 (EV31A) compared with AZ80. Mater Sci Eng A 480:529–539

Kirkland NT, Lespagnol J, Birbilis N, Staiger MP (2010) A survey of bio-corrosion rates of magnesium alloys. Corros Sci 52:287–291

Krawiec H, Szklarz Z, Vignal V (2012) Influence of applied strain on the microstructural corrosion of AlMg2 as-cast aluminium alloy in sodium chloride solution. Corros Sci 65:387–396. doi:10.1016/j.corsci.2012.08.047

Liu M, Qiu D, Zhao M-C et al (2008) The effect of crystallographic orientation on the active corrosion of pure magnesium. Scr Mater 58:421–424

Migliavacca F, Petrini L, Colombo M et al (2002) Mechanical behavior of coronary stents investigated through the finite element method. J Biomech 35:803–811

Moitra A (2013) Grain size effect on microstructural properties of 3D nanocrystalline magnesium under tensile deformation. Comput Mater Sci 79:247–251. doi:10.1016/j.commatsci.2013.05.051

Ng WF, Chiu KY, Cheng FT (2010) Effect of pH on the in vitro corrosion rate of magnesium degradable implant material. Mater Sci Eng C 30:898–903

Nwaogu UC, Blawert C, Scharnagl N et al (2009) Influence of inorganic acid pickling on the corrosion resistance of magnesium alloy AZ31 sheet. Corros Sci 51:2544–2556. doi:10.1016/j.corsci.2009.06.045

Onuma Y, Serruys PW (2011) Bioresorbable scaffold: the advent of a new era in percutaneous coronary and peripheral revascularization? Circulation 123:779–797. doi:10.1161/circulationaha.110.971606

Pachla W, Mazur A, Skiba J et al (2012) Wrought magnesium alloys ZM21, ZW3 and WE43 processed by hydrostatic extrusion with back pressure. Arch Metall Mater. doi:10.2478/v10172-012-0050-3

Pierson D, Edick J, Tauscher A et al (2011) A simplified in vivo approach for evaluating the bioabsorbable behavior of candidate stent materials. J Biomed Mater Res Part B Appl Biomater 100:58–67. doi:10.1002/jbm.b.31922

Rettig R, Virtanen S (2009) Composition of corrosion layers on a magnesium rare-earth alloy in simulated body fluids. J Biomed Mater Res A 88:359–369. doi:10.1002/jbm.a.31887

Schulz C, Herrmann RA, Beilharz C et al (2000) Coronary stent symmetry and vascular injury determine experimental restenosis. Heart 83:462–467

Snir Y, Ben-Hamu G, Eliezer D, Abramov E (2012) Effect of compression deformation on the microstructure and corrosion behavior of magnesium alloys. J Alloys Compd 528:84–90. doi:10.1016/j.jallcom.2012.03.010

Walter R, Kannan MB (2010) Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater Des 32:2350–2354

Walter R, Kannan MB, He Y, Sandham A (2013) Effect of surface roughness on the in vitro degradation behaviour of a biodegradable magnesium-based alloy. Appl Surf Sci 279:343–348. doi:10.1016/j.apsusc.2013.04.096

Winzer N, Atrens A, Dietzel W et al (2008) Characterisation of stress corrosion cracking (SCC) of Mg–Al alloys. Mater Sci Eng A 488:339–351. doi:10.1016/j.msea.2007.11.064

Witte F (2010) The history of biodegradable magnesium implants: a review. Acta Biomater 6:1680–1692

Witte F, Hort N, Vogt C et al (2008) Degradable biomaterials based on magnesium corrosion. Curr Opin Solid State Mater Sci 12:63–72. doi:10.1016/j.cossms.2009.04.001

Wu W, Chen S, Gastaldi D, Petrini L (2012) Experimental data confirm numerical modeling on degradation process of magnesium alloys stents. Acta Biomater. doi:10.1016/j.actbio.2012.10.035

Zhang S, Zhang X, Zhao C et al (2010) Research on an Mg–Zn alloy as a degradable biomaterial. Acta Biomater 6:626–640. doi:10.1016/j.actbio.2009.06.028

Zhang X, Yuan G, Mao L et al (2012) Biocorrosion properties of as-extruded Mg–Nd–Zn–Zr alloy compared with commercial AZ31 and WE43 alloys. Mater Lett 66:209–211. doi:10.1016/j.matlet.2011.08.079

Acknowledgements

The authors would like to acknowledge the provision of project funding by an IRCSET fellowship under the Embark Initiative (RS/2006/82).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest to be declared by the authors.

Rights and permissions

About this article

Cite this article

Galvin, E., Cummins, C., Yoshihara, S. et al. Plastic strains during stent deployment have a critical influence on the rate of corrosion in absorbable magnesium stents. Med Biol Eng Comput 55, 1261–1275 (2017). https://doi.org/10.1007/s11517-016-1584-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11517-016-1584-8