Abstract

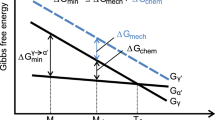

The hardness and fatigue strength achieved by strain hardening are normally noticeable lower than those attained by thermal or thermochemical heat treatments. Strain or deformation induced martensitic transformation of residual austenite can increase the strength achieved by mechanical surface hardening processes considerably. In this paper, an approach is presented where workpieces with a high content of metastable austenite are used for hardening the surface layer. The microstructure has to be sufficiently stable, in order to ensure that the material can be machined without being changed by strain induced transformation of the residual austenite. After machining, high Hertzian contact stresses are introduced by deep rolling, so that a strain induced martensitic transformation of the residual austenite takes place. At the same time deep rolling produces the surface finish of the part. By this method, a surface hardening without a heat treatment process within the production line can be realized. A conceivable use of this method could be the production of bearings or guideways.

Similar content being viewed by others

References

El-Axir MH (2000) An investigation into deep rolling. Int J Mach Tools Manuf 40:1603–1617

Hirsch T, Wohfahrt H, Macherauch E (1987) Fatigue strength of case hardened and shot peened gears. In: Wohlfahrt H, Kopp R, Vöhringer O (eds) Shot peening: science, technology, application. DGM Informationsgesellschaft, Oberursel pp 547–560

Schuhbauer H-G, Bäuerle H, Müller-Stock H-W (1991) Schwingfestigkeitssteigerung schwerer Maschinenbauteile durch Schlagverfestigen. Konferenz-Einzelbericht: Moderne Fertigungs-technologien zur Lebensdauersteigerung, 17. Vortragsveranstaltung des DVM-Arbeitskreises Betriebsfestigkeit, pp 53–64

Röttger K (2003) Walzen hartgedrehter Oberflächen. Dissertation Dr.-Ing. RWTH Aachen. Shaker Verlag, Aachen

Brinksmeier E, Roth P (1990) Hochdruck-Wasserstrahlen—ein neues Verfahren zur mechanischen Randzonenverfestigung. HTM 45:300–306

Tönshoff H-K, Kroos F, Marzenell C (1997) Improving fatigue strength of finished case hardened components by high-pressure water peening. Prod Engineer 4:67–72

Papshev DD (1985) Effektive Methoden der mechanischen Oberflächenverfestigung.Mitteilungen aus dem Institut für Leichtbau und Ökonomische Verwendung von Werkstoffen. Dresden 24:40–43

Schwarmann L (1994) Methoden zur Steigerung der Lebensdauer genieteter Fügungen im Flugzeugbau (Speziell das Aufdornverfahren). Konferenz-Einzelbericht: Fügen im Leichtbau, 20. Vortragsveranstaltung des DVM-Arbeitskreises Betriebsfestigkeit, pp 227–232

Plappert S (2001) Zur Steigerung der Dauerfestigkeit dickwandiger, quergebohrter Rohre durch autofrettage. Dissertation, University of Erlangen-Nürnberg

Greuling S, Seeger T, Vormwald M (2006) Autofrettage innendruckbelasteter Bauteile. Materialwissenschaft und Werkstofftechnik 37:233–239

Reissner J (1999) Innovation potential of materials and their impacts on processing in forming technology. Advanced technology of plasticity, vol 1. Proc of the 6th ICTP, Sept 19–24, pp 409–418

Wei X, Xie Q, Zhang M, Li L, Wollants P (2007) Influence of strain-induced retained austenite transformation on the dynamic tensile behaviour of TRIP-aided steels. Steel Res Int 78:554–559

Razim C (1968) Über den Einfluß von Restaustenit auf das Festigkeitsverhalten einsatzgehärteter Probekörper bei schwingender Beanspruchung. HTM 23:1–8

Kloos K-H, Kaiser B, Adelmann J (1989) Einfluß einer mechanischen Randschichtverfestigung auf die Ermüdungseigenschaften einsatzgehärteter Proben und Zahnräder. In: Broszeit E, Steindorf H (eds) Mechanische Oberflächenbehandlung—Festwalzen, Kugelstrahlen, Sonder-verfahren. DGM Informationsgesellschaft, Oberursel

Tamura I (1982) Deformation-induced martensitic transformation and transformation-induced plasticity in steels. Mater Sci 16:245–253

Weiß A, Gutte H, Scheller P (2006) Deformation induced martensite formation and ist effect on transformation induced plasticity (TRIP). Steel Res Int 77:727–732

Onodera H, Goto H, Tamura I (1976) Effect of volume change on martensitic transformation induced by tensile or compressive stress in polycristalline iron alloys. Proc. 1st JIM Int Symp, Kobe, Japan, pp 327–332

Bayerlein M, Christ H-J, Mughrabi H (1989) Plasticity-induced martensitic transformation during cyclic deformation of AISI 304L stainless steel. Mater Sci Engineer A114:L11–L16

Oettel H, Martin U (2006) The nature of the TRIP-effect in metastable austenitic steels. Int J Mater Res 97:1642–1647

Ganesh SR, Padmanabhan KA (1994) Influence of martensite formation and grain size on room temperature low cycle fatigue behaviour of AISI 304LN austenitic stainless steel. Mater Sci Technol 10:614–620

Garbrecht M (2006) Mechanisches Randschichthärten in der Fertigung. Dissertation Dr.-Ing. Universität Bremen, Shaker-Verlag, Aachen, ISBN 3–8322–5262–2

Lecroisey F, Pineau A (1972) Martensitic transformations induced by plastic deformation in the Fe-Ni-Cr-C system. Metall Trans 3:387–396

Murr LE, Staudhammer KP, Hecker SS (1972) Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: Part II. Microstructural study. Metall Trans 13A:627-663

Acknowledgments

The authors thank for the projects funding by Bundesministerium für Wirtschaft und Technologie (BMWi) via Arbeitsgemeinschaft industrieller Forschungsvereinigungen (AiF) and the assistance of the working commitees “Fertigungstechnik” and “Werkstoffe” of Forschungsvereinigung Antriebstechnik e.V. (FVA) and Arbeitsgemeinschaft Wärmebehandlung und Werkstofftechnik e.V. (AWT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brinksmeier, E., Garbrecht, M., Meyer, D. et al. Surface hardening by strain induced martensitic transformation. Prod. Eng. Res. Devel. 2, 109–116 (2008). https://doi.org/10.1007/s11740-007-0060-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0060-6