Abstract

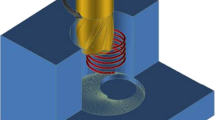

In orbital drilling the tool (special end mill) moves relative to the work piece on a helical course. Because of the three-dimensional tool path and the superimposed rotary cutting motion a complex machining motion results which determines the contact conditions of the tool. The objective of this study is to describe mathematically the occurring cutting conditions over the engagement angle as a function of the technology parameters: bore diameter, tool diameter and the gradient of the helical course. On the basis of this mathematical description further fundamental and qualitative statements regarding the cutting process of orbital drilling can be determined. The theoretical description confirmed a change of the cutting characteristic over the penetration engagement angle of the tool from drilling to milling.

Similar content being viewed by others

References

Brinksmeier E, Fangmann S (2007) Orbital drilling of high tolerance boreholes. In: International conference on applied production technology (APT‘07), BIAS-Verlag, pp 75–84

Teti R (2002) Machining of composite materials, Keynote paper. Ann CIRP 51(2):611–634

Brinksmeier E, Janssen R (2002) Drilling of multi-Layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminium alloys. Ann CIRP 51(1):87–90

Brinksmeier E, Krogmeier F, Walter A (2005) Bohrungsbearbeitung von mehrschichtigen Compound-Werkstoffen. In: Spanende Fertigung, 4. Ausgabe. Vulkan Verlag, Essen, pp 43–50

Denkena B, Dege J (2007) Zirkularfräsen von Schichtverbunden aus CFK und Titan, Begleitband zum Seminar: Neue Fertigungstechnologien in der Luft- und Raumfahrt 28./29.11.2007, Berichte aus dem IFW Band 11/2007, pp 85–98

Tönshoff H-K, Friemuth T, Groppe M (2001) High efficient circular milling—a solution for an economical machining of bore holes in composite materials (CFK, Aluminium). In: Proceedings of the 3rd international conference on metal cutting and high speed machining, Metz

Weinert K, Hammer N (2004) Zirkularfräsen von Bohrungen im Leichtbau. WB Werkstatt und Betrieb 137(10):54–58

Altintas Y et al (1996) A general mechanics and dynamics model for helical end mills. Ann CIRP 45(1):59

Tönshoff HK (1995) Spanen. Grundlagen. Springer, Berlin

Nakayama K et al (1998) Basic rules on the form of chip in metal cutting. Ann CIRP 27(1):17–21

Denkena B, Tracht K, Schmidt C (2006) A flexible force model for predicting cutting forces in end milling. Prod Eng XIII/2:15–20

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s11740-010-0210-0

Rights and permissions

About this article

Cite this article

Brinksmeier, E., Fangmann, S. & Meyer, I. Orbital drilling kinematics. Prod. Eng. Res. Devel. 2, 277–283 (2008). https://doi.org/10.1007/s11740-008-0111-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0111-7