Abstract

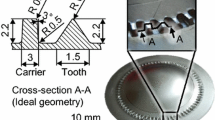

The aim of this paper is to optimize the analytical model developed in previous work (Hu et al. in Determination of the friction coefficient in deep drawing, process scaling. In: Vollertsen F, Hollmann F (eds) Proceeding of the 1st colloquium of DFG priority program process scaling. BIAS-Verlag, ISBN 3-933762-14-6, Bremen, pp 27–34, 2003; Hu and Vollertsen in J Technol Plast 29:1–9, 2004; Vollertsen and Hu in Annu CIRP 55(1):291–294, 2006) with respect to the distribution of the contact pressure at the drawing radius. A size-dependent friction function was acquired based on the experimentally measured punch force from strip drawing with deflection, which can identify the tribological size effects in sheet metal forming. This function was implemented in the FEM-simulation. The distribution of the contact pressure at the drawing radius was assumed to be uniform in the previous analytical model, which is not right, since the simulated punch force versus punch travel curve showed a difference of about 11% from the experimental curve (Vollertsen and Hu in Annu CIRP 55(1):291–294, 2006). In the new analytical model the non-uniform distribution of contact pressure between the work piece and the tools was taken into account. The simulated curve using the friction function from the new model shows a better agreement with the experimental curve.

Similar content being viewed by others

References

Hu Z, Schulze Niehoff H, Vollertsen F (2003) Determination of the friction coefficient in deep drawing, process scaling. In: Vollertsen F, Hollmann F (eds) Proceeding of the 1st colloquium of DFG priority program process scaling. BIAS-Verlag, ISBN 3-933762-14-6, Bremen, pp 27–34

Hu Z, Vollertsen F (2004) A new friction test method. J Technol Plast 29:1–9

Vollertsen F, Hu Z (2006) Tribological size effects in sheet metal forming measured by a strip drawing test. Annu CIRP 55(1):291–294

Olssen DD, Bay N (2004) Prediction of limits of lubrication in strip reduction testing. Ann CIRP 53(1):231–234

Becker P, Jeon HJ, Chang CC, Bramley AN (2003) A geometric approach to modelling friction in metal forming. Ann CIRP 52(1):209–212

Vollertsen F, Hu Z, Schulze H, Niehoff C (2004) Theiler: state of the art in micro forming and investigations into micro deep drawing. J Mater Process Technol 151:70–79

Engel U (2006) Tribology in microforming. Wear 260(3):265–273

Geiger M, Messner A, Engel U (1997) Production of microparts—size effects in bulk metal forming, similarity theory. Prod Eng 4(1):55–58

Hoffmann H, Hong S (2006) Tensile test of very thin sheet metal and determination of flow stress considering the scaling effect. Ann CIRP 55(1):263–266

Lange K (1990) Umformtechnik—Handbuch für Industrie und Wissenschaft, Band 3: Blechbearbeitung. Springer, Berlin

Storoschew MW, Popow EA (1968) Grundlagen der Umformtechnik. Verlag Technik, Berlin

Kluge S, Wolf H (1991) Berechnen des Biegekraftanteils beim Umformen von Blechen, Bänder Bleche Rohre 11:46–54

Sass F, Bouché CH, Leitner A (1974) DUBBEL, Taschenbuch für den Maschinenbau, Erster Band. Springer, Berlin

Acknowledgments

The work reported in this paper is funded by the Deutsche Forschungsgemeinschaft (DFG) within the project “Modelling of tribological size-effects in deep drawing” (DFG project no. Vo 530/6). The authors would like thank the DFG for their beneficial support. Moreover the authors would like thank the institute of Metal Forming and Casting (UTG) in Munich in Germany for carry out the tensile test for the Al99.5 in thicknesses of 0.02, 0.1, and 0.2 mm.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vollertsen, F., Hu, Z. Determination of size-dependent friction functions in sheet metal forming with respect to the distribution of the contact pressure. Prod. Eng. Res. Devel. 2, 345–350 (2008). https://doi.org/10.1007/s11740-008-0130-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0130-4