Abstract

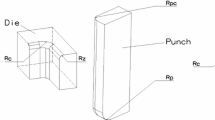

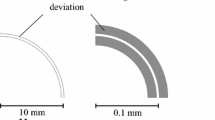

Micro forming is an appropriate technology to manufacture very small metal parts, in particular for bulk production, as they are required in many industrial products resulting from micro technology. Deep drawing provides a great application potential for the manufacturing of parts with complex shapes, even in very small dimensions. Concerning the so called size effects micro deep drawing is widely investigated. However, this process is carried out usually under laboratory conditions with a relatively low punch velocity, for example 1 mm/s. At the same time, the light weight of the forming tools for micro deep drawing makes it possible to vary the punch velocity in a relatively large range. Furthermore, raising the punch velocity is very meaningful for mass production in industry. Thus micro deep drawing with the punch diameter of 1 mm was performed with different punch velocities (1, 10 and 100 mm/s) in this work, whereby the process behaviour, especially the experimentally acquired process window changes with variation of punch velocities. The analysis in this work shows that the velocity dependent friction coefficients are responsible for the difference in process windows under different punch velocities.

Similar content being viewed by others

References

Geiger M, Kleiner M, Eckstein R, Tiesler N, Engel U (2001) Microforming. CIRP An006E 50(2):445–462

Wicht H, Bouchaud J (2005) Panorama - NEXUS Market Analysis for MEMS and Microsystems III 2005–2009. MST news—Int Newsl Micro-Nano Integr 5(05):33–34

Tiesler N, Engel U (2000) Microforming—Effects of Miniaturisation, In: Pietrzyk M, Kusiak J et al (eds) Proceedings of 8th international conference on metal forming, Kraków, pp 355–360

Pawelski O (1993) Aehnlichkeitstheorie in der Umformtechnik. In: Dahl W, Kopp R, Pawelski O (eds) Umformtechnik Plastomechanik und Werkstoffkunde. Verlag, Düsseldorf

Vollertsen F, Hu Z (2008) Determination of size-dependent friction functions in sheet metal forming with respect to the distribution of the contact pressure. Prod Eng Res Dev 2:345–350

Vollertsen F, Biermann D, Hansen HN, Jawahir IS, Kuzman K (2009) Size effects in manufacturing of metallic components. Ann CIRP 58(2):556–587

Vollertsen F, Hu Z (2006) Tribological size effects in sheet metal forming measured by a strip drawing test. Ann CIRP 55(1):291–294

Hoffmann H, Hong S (2006) Tensile test of very thin sheet metal and determination of flow stress considering the scaling effect. Ann CIRP 55(1):263–266

Vollertsen F, Hu Z, Schulze Niehoff H, Theiler C (2004) State of the art in micro forming and investigations into micro deep drawing. J Mater Process Technol 151:70–79

Hirt G, Justinger H, Witulski N (2003) Analysis of Size effects in micro sheet forming, In: Vollertsen F, Hollmann F (eds) BIAS-Verlag, ISBN 3-933762-14-6, Strahltechnik, 24:27–34

Hu Z, Walther R, Vollertsen F (2009) Influence of size effects on the process window for deep drawing, In: Levy BS, Matlock DK, Van Tyne CJ (eds) IDDRG 2009:international conference, June 1–3, Golden/USA, ISBN 978-0-615-29641-8, pp 785–796

Schulze Niehoff H (2008) Entwicklung einer hochdynamischen, zweifachwirkenden Mikroumformpresse, Dissertation, Strahltechnik Band 33, BIAS Verlag, Bremen, ISBN 978-3-933762-25-2

Carignan FJ, Rabinowicz E (1979) Friction and wear at high sliding speed. ASLE Trans 24(4):451–459

Wagner S (1992) Ermittlung der Reibungszahlen für das Ziehen von Aluminiumblechen, Neuere Entwicklungen in der Blechumformung, Hrsg. Klaus Siegert, MAT-INFO Werkstoff-Informationsgesellschaft, pp 487–507

Lange K (1984) Umformtechnik—Handbuch fuer Industrie und Wissenschaft Band 1 Grundlagen. Springer, Berlin. ISBN 3-540-43686-3

Storoschew MW, Popow EA (1968) Grundlagen der Umformtechnik. VEB Verlag Technik, Berlin

Herzig N, Meyer LW (2006) Material characterisation at high strain rates with special emphasis on miniaturisation and size dependencies, In: Proceedings 2nd ICHSF, Dortmund, ISBN 3-00-018432-5, pp 13–22

Nicholas T (1981) Tensile testing of materials at high rates of strain. Exp Mech 21(5):177–185

Hu Z, Schulze Niehoff H, Vollertsen F (2007) Tribological size effects in deep drawing, ICNFT2007, In: Vollertsen F and Yuan S (eds) BIAS Verlag, Bremen, Germany: pp 573–582

Engel U (2006) Tribology in microforming. Wear 260(3):265–273

Hu Z (2009) Analyse des tribologischen Größeneffekts beim blechumformen, Dissertation, Strahltechnik band 37, BIAS-Verlag, ISBN 978-3-933762-30-6

Rabinowicz E (1992) Friction coefficients of noble metals over a range of loads. Wear 159:89–94

Filzek J, Groche P (2001) Assessment of the tribological function of lubricants for sheet metal forming. ASTM STP, Band 1404:97–108

Hu Z, Schulze Niehoff H, Vollertsen F (2008) Determination of friction function in deep drawing with respect to size effects, In:Yang DY, Kim YH Park CH (eds) ICTP 2008: 9th International conference on technology of plasticity, ISBN 978-89-5708-151-8, Gyeongiu, Korea, pp 281–282

Vollertsen F, Hu Z (2007) On the drawing limit in micro deep drawing. J Technol Plast 32(1–2):1–11

Acknowledgments

The work reported in this paper is funded by the Deutsche Forschungsgemeinschaft (DFG) within the Collaborative Research Centre 747 “Micro Cold Forming” (subproject B3). The authors would like to thank the DFG for their financial support. Moreover the authors would like to thank the Stiftung Institut fuer Werkstofftechnik (IWT) in Bremen in Germany for carrying out the tensile test for the Al99.5 in thicknesses of 0.02 mm.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vollertsen, F., Hu, Z. Analysis of punch velocity dependent process window in micro deep drawing. Prod. Eng. Res. Devel. 4, 553–559 (2010). https://doi.org/10.1007/s11740-010-0241-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0241-6