Abstract

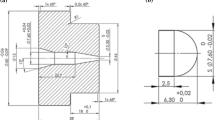

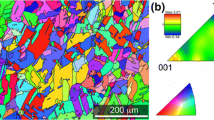

The Finite Element Analysis (FEA) is a suitable tool for the process design and the determination of technical failure. Within this paper, the FEA is used for simulating and analyzing the thread milling process and the tapping process for reinforced lightweight extrusion profiles. Two different finite element models are developed to simulate both processes. An elastic material behavior is implemented in the simulation. For the tapping process, the computed stresses during the process as well as the geometrical displacements are considerably higher than the stresses computed for the thread milling operation. This is caused by the lower mechanical loads occurring in the thread milling process. The results can be used to identify areas of high stresses which may cause material failure. Moreover, both processes can be analyzed with respect to their influence on the workpiece. The simulation results are compared to experiments.

Similar content being viewed by others

References

Biermann D, Weinert K, Zabel A, Engbert T, Rautenberg J (2008) Machining of lightweight frame components. Adv Mat Res 43:37–46

Rai JK, Xirouchakis P (2009) FEM-based prediction of work piece transient temperature distribution and deformations during milling. Int J Adv Manuf Technol 42(5/6):429–449

Weinert K, Hammer N, Peters C, Schulte M (2004) Finite element modeling concepts of the load application on thin-walled profiles during the drilling process. Prod Eng 112:121–124

Attanasio A, Ceretti E, Rizzuti S, Umbrello D, Micari F (2008) 3D finite element analysis of tool wear in machining. CIRP Ann-Manuf Technol 57:61–64

Weinert K, Grünert S, Hammer N, Kersting M (2005) Analysis of circular millling processes for thin-walled space-frame-structures applying fea-simulation. Production Engineering—Research and Development, Annals of the German Academic Society for Production Engineering, XII, 2. pp 99–102

Weinert K, Kersting M, Schulte M, Peters C (2005) Finite element analysis of thermal stresses during the drilling process of thin-walled profiles. Production Engineering—Research and Development, Annals of the German Academic Society for Production Engineering, XII, 1. pp 101–104

Biermann D, Grünert S, Steiner M (2009) FEM-simulation of machining reinforced lightweight-structures. Proceedings of the 7th international conference on manufacturing research, Warwick, England, pp 54–59

Miller SF, Li R, Wang H, Shih AJ (2006) Experimental and numerical analysis of the friction drilling process. J Manuf Sci Eng 128:802–810

Spur G (1980) Handbuch der fertigungstechnik 3/2. Hanser Verlag, München, ISBN 3-446-12648-1

Zaeh MF, Schwarz F (2009) Implementation of a process and structure model for turning operations. Prod Eng Res Dev 3(2):197–205

Fröhlich P (2005) FEM-anwendungspraxis: einstieg in die finite elemente analyse-zweisprachige ausgabe deutsch/englisch, 1 Edition, Vieweg Verlag, ISBN 3-528-03972-8

Acknowledgments

This paper is based on investigations of the Collaborative Research Center SFB/TR10 which is kindly supported by the German Research foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biermann, D., Grünert, S. & Steiner, M. A macroscopic approach towards the finite element simulation of tapping and thread milling of continuously reinforced extrusions. Prod. Eng. Res. Devel. 4, 607–613 (2010). https://doi.org/10.1007/s11740-010-0270-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0270-1