Abstract

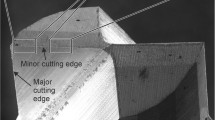

During the machining process, high mechanical and thermal loads occur at the cutting edge. Such loads can cause tool failure. Specifically non-uniform and sharp cutting edges that have a low cutting edge stability lead to such failures. In order to enhance the tool performance, the cutting edges are prepared by manufacturing both a pre-defined cutting edge geometry, and an appropriate cutting edge roughness. This paper describes the use of a low-cost marking laser for the preparation of cutting edges as an alternative to conventional preparation techniques, such as brushing or blasting. Cutting edge radii of 9–47 μm can be prepared with a machining accuracy of 1.5 μm. The maximum preparation time for an individual cutting edge is approximately 10 s. Uncoated indexable inserts manufactured in this way were tested in a face milling operation. The results of these investigations (using prepared cutting edges) show both an increase in tool life and an improved surface roughness of the machined workpieces compared to those using non-prepared cutting edges.

Similar content being viewed by others

References

Byrne G, Dornfeld D, Denkena B (2003) Advancing cutting technology. Annals of the CIRP 52(2):483–507

Biermann D, Weinert K, Terwey I, Denkena B, Haubrock J (2009) Vorteile durch Verrundung. Einsatzverhalten komplexer Werkzeuge mit präparierten Schneidkanten. WB Werkstatt und Betrieb 142(11):36–40

Shaffer B (2005) Advances in edge preparation offer production advantages. Tool Prod 71:14–16

Byelyayev O (2008) Erhöhung der Leistungsfähigkeit von HSS-Spiralbohrern durch Einsatz der magnetabrasiven Bearbeitung. Dissertation, University Magdeburg

Denkena B, Weinert K, Friemuth T, Spengler C, Schulte M, Kötter D (2003) Kantenpräparation an Hartmetall Werkzeugen–Einfluss der Prozessparameter beim Strahlen und Bürsten. VDI-Z Special Werkzeuge 3:51–54

Denkena B, Kramer N, Siegel F, Kästner J (2007) Methoden zur Präparation von Zerspanwerkzeugen: Leistungsoptimierung an der Schneidkante. VDI-Z Special Werkzeuge 8:24–26

Ostendorf A, Kulik C, Siegel F (2004) Cutting tools preparation using short pulse lasers. LANE, Laser Assisted Net Shape Engineering 4:681–690

Rech J, Yen Y C, Hamadi H, Altan T, Bouzakis K D (2004) Influence of cutting edge radius of coated tool in orthogonal cutting of alloy steel. In: Proceedings of the 8th international conference on numerical methods in industrial forming processes 712:1402–1407

Rech J (2005) Influence of cutting edge radius on the wear resistance of PM-HSS milling inserts. Wear 259:1168–1176

Denkena B, Friemuth T, Fedorenko S, Groppe M (2002) An der Schneide wird das Geld verdient. Werkzeugtechnik+Verfahren 30(12):24–26

Kordt J (2007) Konturnahes Laserstrahlstrukturieren für Kunststoffspritzgießwerkzeuge. Dissertation, RWTH Aachen

Tönshoff HK, Friemuth T (1999) Effects of grinding on the performance of cutting tools. Prod Eng 6(2):9–12

Guter T (2009) Kantenpräparation an Wendeschneidplatten, Kantenpräparation an Wendeschneidplatten–der Schlüssel zu leistungsstarker Zerspanung. In: Tikal F Schneidkantenpräparation, Ziele, Verfahren und Messmethoden. Kassel, University press, pp 71–86

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aurich, J.C., Zimmermann, M. & Leitz, L. The preparation of cutting edges using a marking laser. Prod. Eng. Res. Devel. 5, 17–24 (2011). https://doi.org/10.1007/s11740-010-0275-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0275-9