Abstract

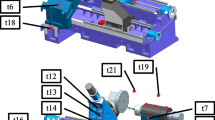

The thermal behavior of a machine tool is an important indicator for the grade of production accuracy and indirectly for the market success. The load-dependent temperature distribution and the resulting deformation of the machine tool are influenced by a variety of design and thermo-technical parameters. The main spindle of a machine tool is, without any doubt, the major heat source within the machine structure. The object of the scientific investigation presented in this article is the development of an approach to robust compensation of thermo-dependent machine tool deformations due to spindle load in consideration of rough machining. The focus of the work concentrates on the identification of the model with the highest compensation performance. The underlying concept for the compensation of thermo-dependent machine tool deformations is the indirect approach by using the speed and the effective power of the main spindle for the calculation of the Tool Center Point (TCP) displacement. The presented modeling approach requires the knowledge of the TCP displacement in X-, Y- and Z-direction depending on the speed and the effective power of the main spindle. As a tool for modeling the thermo-dependent behavior of a milling machine, a load test rig for repeatable, defined long-term loading of the main spindle has been developed. It simulates the cutting force depending on the spindle speed and the torque and applies load to the main spindle. The spindle speed and the spindle effective power can be taken directly from the numerical control of the machine tool. An important advantage of the presented compensation method is the fact that it does not require any external sensors. The displacement of the TCP has to be measured, but only during modeling. The relationship between the speed/power of the main spindle as a cause and the displacement of the TCP in X-, Y- and Z-direction as an effect can be determined by a transfer function. This paper compares the compensation results depending on the transfer function and identifies the model with the best compensation performance. The validation of the compensation method is executed by using the example of two different speed and power spectra of the main spindle.

Similar content being viewed by others

References

Brecher C, Hoffmann F, Gerrath T, Schapp L, Weck M, Hirsch P (2006) Messtechnische Untersuchung von Prozess und Maschine, Beurteilung und Abnahme von Werkzeugmaschinen (ab 1960). In: Weck M (ed) 100 Jahre Produktionstechnik. Springer, Berlin, pp 437–448

Bryan J (1990) International status of thermal error research. Ann CIRP 39:645–656

Großmann K, Jungnickel G (2006) Prozessgerechte Bewertung des thermischen Verhaltens von Werkzeugmaschinen, 1st edn. Technische Universität Dresden, Dresden

Wulfsberg JP (1991) Diagnose und Kompensation thermischer Verlagerungen in Schleifmaschinen, 1st edn. Universität Hannover, Hannover

Koscàk G (2007) Ermittlung des instationären thermischen Verhaltens von Vorschubachsen mit Kugelgewindetrieb mit Hilfe der Verarbeitung thermografischer Messdaten, 1st edn. Universität Stuttgart, Stuttgart

Du ZC, Yang JG, Yao ZQ, Xue BY (2002) Modelling approach of regression orthogonal experiment design for the thermal error compensation of a CNC turning center. J Mater Process Technol 129:619–623

Lee DS, Choi JY, Choi DH (2003) ICA based thermal source extraction and thermal distortion compensation method for a machine tool. Int J Mach Tools Manuf 43:589–597

Neugebauer R, Weidermann F, Nestmann S (2002) A modeling approach to optimize the thermal behaviour of machine tool components. Prod Eng 9:131–134

Denkena B, Scharschmidt K-H (2007) Kompensation thermischer Verlagerungen: Berechnung thermischer Verformungen von Werkzeugmaschinen auf Basis von Temperaturmessungen. wt Werkstattstechnik 97:913–917

Kang Y, Chang C-W, Huang Y, Hsu C-L, Nieh I-F (2007) Modification of a neural network utilizing hybrid filters for the compensation of thermal deformation in machine tools. Int J Mach Tools Manuf 47:376–387

Mitsuishi M, Okumura T, Nagao T, Hatamura Y (1994) Active thermal deformation compensation based on internal monitoring and a neural network. In: Advancement of intelligent production, pp 215–220

Mize CD, Ziegert JC (2000) Neural network thermal error compensation of a machining center. Precis Eng 24:338–346

Pahk H, Lee SW (2002) Thermal error measurement and real time compensation system for the CNC machine tools incorporating the spindle thermal error and the feed axis thermal error. Int J Adv Manuf Technol 20:487–494

Bonse R (1999) Thermisches Last-Verformungsverhalten von Werkzeugmaschinen, 1st edn. Shaker, Aachen

Heisel U, Stehle T (1997) Fuzzy-Logik zur Bestimmung des thermischen Verhaltens. Berechnung thermischer Verlagerungen an Werkzeugmaschinen und Möglichkeiten zur Kompensation Teil 2. Die Maschine 51:52–56

Hong'en W, Guili L, Daguang S, Chengrui Z (2006) Fuzzy logic thermal error compensation for computer numerical control noncircular turnning system. In: 9th International Conference on Control, Automation, Robotics and Vision, (ICARCV '06). Piscataway, NJ. IEEE, pp S1–S5, 5–8 December 2006. ISBN 1-4244-0341-3

Lee J-H, Yang S-H (2001) Thermal error modeling of a horizontal machining center using fuzzy logic strategy. J Manuf Process 3:120–127

Wang K-C, Tseng P-C, Lin K-M (2006) Thermal error modeling of a machining center using grey system theory and adaptive network-based fuzzy inference system. Int J Ser C Mech Syst Mach Elem Manuf 49:1179–1187

Moriwaki T, Shamoto E (1998) Analysis of thermal deformation of an ultra precision air spindle system. CIRP Ann 47:283–286

Brecher C, Hirsch P, Weck M (2004) Compensation of thermo-elastic machine tool deformation based on control internal data. CIRP Ann 53:299–304

McClure ER, Thal-Larson H (1971) Thermal effects in precision machining. J Mech Eng 93:11–14

Hornych J, Barta P, Mares M (2009) Thermomechanical transfer functions and control of a machine tool cooling system. MM Sci J S96–S97. ISSN 1803-1269

Horejs O et al (2009) Determination of thermo-mechanical state of a cooled ball. In: Conference proceedings of the 9th international conference of the EUSPEN, pp 216–219

Hornych J et al (2009) Issues in identification of the thermal transfer functions of machine tools. In: Proceedings of the 9th international conference of the EUSPEN, pp 451–454

Horejs O, Mares M, Kohut P, Barta P, Hornych J (2010) Compensation of machine tool thermal errors based on transfer functions. MM Sci J S162–S165. ISSN 1803-1269

Barta P et al (2007) Thermal transfer function based control method of a machine tool cooling system. In: Proceedings of the topical meeting: thermal effects in precision systems, Maastricht, pp 16–18

Fraser S, Attia M, Osman M (1998) Modelling, identification and control of thermal deformation of machine tool structure, part 1: concept of generalized modelling. J Manuf Sci Eng 120:623–631

Fraser S, Attia M, Osman M (1998) Modelling, identification and control of thermal deformation of machine tool structure, part 2: generalized transfer functions. J Manuf Sci Eng 120:632–639

Fraser S, Attia M, Osman M (1998) Modelling, identification and control of thermal deformation of machine tool structure. Part 3: Real-time estimation of heat sources. J Manuf Sci Eng 121:501–508

Fraser S, Attia M, Osman M (1998) Modelling, identification and control of thermal deformation of machine tool structure, part 4: a multi-variable closed-loop control system. J Manuf Sci Eng 121:509–516

Fraser S, Attia M, Osman M (1998) Modelling, identification and control of thermal deformation of machine tool structure, part 5: experimental verification. J Manuf Sci Eng 121:517–523

Moriwaki T (1988) Thermal deformation and its on-line compensation of hydrostatically supported precision spindle. Ann CIRP 37:393–396

Rauer J (1992) Experimentelle Modellierung des thermischen Systems von Drehspindeleinheiten. Wiss Zeitschrift der TU Otto von Guericke Magdeburg 36:29–34

Chen JS, Yuan JX, Ni J, Wu SM (1993) Real-time compensation for time-variant volumetric errors on a machining center. J Eng Ind 115:472–479

Großmann K, Jungnickel G (1999) Genauigkeitssteigerung an Werkzeugmaschinen. ZWF 94:320–323

Brecher C, Wissmann A (2009) Modelling of thermal behaviour of a milling machine due to spindle load. In: Proceedings of the 12th CIRP conference on modelling of machining operations, pp 673–678

Brecher C, Wissmann A (2009) Optimierung des thermischen Verhaltens von Fräsmaschinen. Zeitschrift für wirtschaftlichen Fabrikbetrieb 6:437–441

Abel D (2009) Regelungstechnik, 33rd edn. Verlag Mainz, Aachen

Brecher C, Wissmann A (2009) Stressing unit for modelling of thermal behaviour of a milling machine. In: Proceedings of the 12th CIRP conference on modelling of machining operations, pp 727–730

Dittmar R, Pfeiffer B-M (2004) Modellbasierte prädiktive Regelung—Eine Einführung für Ingenieure, 1st edn. Oldenbourg-Verlag, Munich

Acknowledgments

The presented scientific work was a part of the research project ‘NEXT GENERATION PRODUCTION SYSTEMS’ supported by the European Commission under the Sixth Framework Programme. The authors acknowledge financial support from EC grant IP 011815.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brecher, C., Wissmann, A. Compensation of thermo-dependent machine tool deformations due to spindle load: investigation of the optimal transfer function in consideration of rough machining. Prod. Eng. Res. Devel. 5, 565–574 (2011). https://doi.org/10.1007/s11740-011-0311-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-011-0311-4