Abstract

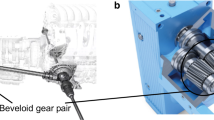

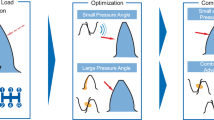

Beveloid gears, also known as conical involute gears, gain more and more importance in industrial practice. They are based on cylindrical gears, but have a variable profile shift along their tooth width. For some time, beveloid gears have been applied to marine transmissions (Winkler 2002; Zhu et al. in Chin J Mech Eng 25:328–337, 2012), but in the last years they have been used increasingly in the automotive industry (Börner et al. in Gear Technol 6:28–35, 2005; Alxneit 2010). A crucial step of the manufacturing process is the grinding process that is necessary to achieve high load carrying capacity and low noise vibration harshness (NVH). During the grinding process the micro-geometry of the tooth flanks can be modified in order to increase the gear quality. For the generation grinding process of beveloids, two types of machine kinematics and two tool concepts are known. The different machine kinematics and tool concepts may lead to unintentional changes in micro-geometry of the flanks which has an impact on load carrying capacity and NVH qualities of the gear. Up to now, no research has been made to quantify the influence of the machine kinematics and the tool concept on load carrying capacity and NVH. Therefore, these influences are analyzed in this work by simulating the gear manufacturing with the help of the two known machine kinematics as well as the two known tool concepts and by meshing the simulated gears in an FE-based tooth contact analysis (TCA). The results of the TCA are parameters regarding the running behavior which are analyzed and compared for the four aforementioned manufacturing concepts.

Similar content being viewed by others

Abbreviations

- a:

-

Distance between axles

- b:

-

Gear width

- Ca :

-

Tip relief

- CVα :

-

Twist

- Cβ :

-

Lead crowning

- d0 :

-

Tool radius

- D1 :

-

Mounting distance of gear 1

- D2 :

-

Mounting distance of gear 2

- da :

-

Tip diameter

- dCa :

-

Diameter of the tip relief start

- FE:

-

Finite elements

- fHα :

-

Profile angle modification

- fHβ :

-

Helix angle modification

- H:

-

Heel

- haP0 :

-

Addendum

- hfP0 :

-

Dedendum

- NVH:

-

Noise vibration harshness

- M:

-

Middle

- mn :

-

Normal module

- T:

-

Toe

- T1 :

-

Torque at gear 1

- TCA:

-

Tooth contact analysis

- z:

-

Number of teeth

- Σ:

-

Crossing angle

- xe :

-

Generation profile shift

- z0 :

-

Number of starts

- αn, αP0 :

-

Normal pressure angle

- β:

-

Helix angle

- εγ :

-

Contact ratio

- θa:

-

Tip cone angle

- θf :

-

Root cone angle

- ρaP0 :

-

Tip radius

- σFP :

-

Flank pressure

- σv :

-

Maximal von mises stress

References

Winkler T (2002) Untersuchungen zur Belastbarkeit hohlkorrigierter Beveloidgetriebe für Schiffsgetriebe mittlerer Leistung. Dissertation, Universität Stuttgart

Zhu C, Song C, Lim TC, Vijayakar S (2012) Geometry design and tooth contact analysis of crossed beveloid gears for marine transmissions. Chin J Mech Eng 25:328–337

Börner J, Humm K, Joachim FJ (2005) Development of conical involute gears (beveloids) for vehicle transmissions. Gear Technol 6:28–35

Alxneit H (2010) Optimierung des Übertragungsverhaltens konischer Außenstirnräder mit kreuzenden Achsen. Dissertation, Universität Stuttgart

Brecher C, Gorgels C, Röthlingshöfer T (2009) Manufacturing simulation of beveloid gears for the use in a general tooth contact analysis software. Prod Eng Res Dev 3:103–109

Brecher C, Weck M (2005) Werkzeugmaschinen—Maschinenarten und Anwendungsbereiche. Springer, Berlin

Roth K (1998) Zahnradtechnik Evolventen-Sonderverzahnungen zur Getriebeverbesserung. Springer, Berlin

Mitome K (1991) Conical involute gear—Design of nonintersecting-nonparallel-axis conical involute gear. JSME Int J 34:265–270

Tsay CB, Liu CC (2002) Mathematical models and contact simulations of concave beveloid gears. J Mech Des 124:753–760

Brecher C, Gorgels C, Hellman M (2011) Berücksichtigung von verfahrensbedingten Verschränkungen bei der Verzahnungsauslegung. In: GETPRO—Kongress zur Getriebeproduktion 29./30.03.2011, pp 129–154

Röthlingshöfer T (2012) Auslegungsmethodik zur Optimierung des Einsatzverhaltens von Beveloidverzahnungen. Dissertation, RWTH Aachen

Hemmelmann J (2007) Simulation des lastfreien und belasteten Zahneingriffs zur Analyse der Drehübertragung von Zahnradgetrieben. Dissertation, RWTH Aachen

Brecher C, Brumm M, Henser J (2011) Simulation von Beveloidverzahnungen—Berechnung der Zahnfußspannungen. In: Dresdner Maschinenelemente Kolloquium 29./30.11.2011, pp 227–245

Brecher C, Gorgels C, Flodin A et al (2010) 3D tooth contact analysis—Simulation possibilities for PM gears. In: World PM2010 conference proceedings—EPMA 10th–14th October

Litvin FL (1994) Gear geometry and applied theory. PTR Prentice Hall, New Jersey

VDE-Standard VDE 2607 (2000) Computer aided evaluation of profile and helix measurements on cylindrical gears with involute profile. Beuth Verlag GmbH, Berlin

International Standard ISO 6336 (2007) Calculation of the load carrying capacity of spur and helical gears. Beuth Verlag GmbH, Berlin

Smith JD (2003) Gear noise and vibration. Marcel Dekker Inc., New York

Acknowledgments

The investigations described in the present paper were conducted as a part of a project sponsored by Deutsche Forschungsgemeinschaft (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brecher, C., Brumm, M., Hübner, F. et al. Influence of the manufacturing method on the running behavior of beveloid gears. Prod. Eng. Res. Devel. 7, 265–274 (2013). https://doi.org/10.1007/s11740-012-0442-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0442-2