Abstract

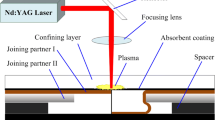

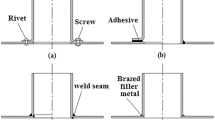

The need to implement more functionality on the same space drives miniaturization and makes hybrid joints under various conditions also in the micro range necessary. Existing solutions often have restrictions due to the principle of joining. Thus, in this article a new high speed joining method for the micro range is presented, which is realized by a plastic forming process based on TEA-CO2-laser induced shockwaves. In a first step it is shown how sheet–sheet joints can be realized with this method. In order to get knowledge of basic process parameter and for further application of the process, the near-by-field of acting pressure of the initiated shock wave is measured in open and tube environment. The results show that constant maximum acting pressure conditions appear in a tube, while pressure characteristics show high reflection phenomena. Furthermore, it is determined that the ignition point of the TEA-CO2-laser induced plasma out of aluminum is about 8 mm above the surface.

Similar content being viewed by others

References

Vollertsen F, Biermann D, Hansen HN, Jawahir IS, Kuzman K (2009) Size effects in manufacturing of metallic components. CIRP Ann Manuf Technol 58(2):566–587

Sam R, Yu B, Chen M, Eagleson M (2001) Advances in laser microwelding. In: Chen X (ed) Proceedings of 20th international congress on applications of lasers and electro-optics (ICALEO 2001). 15–18 Oct 2001, Jacksonville, FL, USA, F402

Kamada K, Nakamura Y, Ohmori A, Matsunawa A, Katayama S, Arata Y (1987) Application of laser welding to production of micro-motor coil. In: Proceedings of international conference on laser advanced materials processing (LAMP ‘87). May 21–23 1987, Osaka, Japan, pp 573–578

Smolka G, Gillner A, Bosse L, Lützeler R (2004) Micro electron beam welding and laser machining—potentials of beam welding methods in the micro-system technology. Microsyst Technol 10:187–192

Neugebauer R, Bouzakis K-D, Denkena B, Klocke F, Sterzing A, Tekkaya AE, Wertheim R (2011) Velocity effects in metal forming and machining processes. CIRP Ann Manuf Technol 60(2):627–650

Zhang Y, Babu S, Daehn GS (2010) Impact welding in a variety of geometric configurations. In: 4th international conference on high speed forming, pp 97–107

Patent (USA) (2011) Low-temperature spot impact welding driven without contact. Pub. No. US 2011/0000953 A1

Zhang Y, Suresh Babu S, Prothe C, Blakely M, Kwasegroch J, LaHa M, Daehn GS (2011) Application of high velocity impact welding at varied different length scales. J Mater Process Technol 211:944–952

Demtröder W (2010) Atoms, molecules and photons an introduction to atomic-, molecular-, and quantum-physics, 2nd edn. Springer, Berlin, p 37

Miziolek AW, Palleschi V, Schechter I (2006) Laser induced breakdown spectroscopy, 1st edn. Cambridge University Press, Cambridge

Barchukov AI, Bunkin FV, Konov VI, Lyubin AA (1974) Investigation of low-threshold gas breakdown near solid targets by CO2 laser radiation. Sov Phys-JETP 39–3:469–477

O’Keefe JD, Skeen CH, York CM (1973) Laser-induced deformation modes in thin metal targets. J Appl Phys 44(10):4622–4626

Walter D, Michalowski A, Gauch R, Dausinger F (2007) Monitoring of the micro-drilling process by means of laser-induced shock waves. In: Vollertsen F, Emmelmann C, Schmidt M, Otto A (eds) Proceedings of the fourth international WLT-conference on lasers in manufacturing (LIM07). AT-Fachverlag, Stuttgart, pp 557–562

Zhang W, Yao YL, Noyan IC (2004) Microscale laser shock peening of thin films, part 1: experiment, modeling and simulation. ASME 126:10–17

Vollertsen F, Schulze Niehoff H, Wielage H (2009) On the acting pressure in laser deep drawing. Prod Eng Res Dev 3(1):1–8

Wielage H, Vollertsen F (2010) Increase of acting pressure by adjusted tool geometry in laser shock forming. In: Chinesta F, Chastel Y, El Mansori M (eds) Proceedings of international conference on advances in materials and processing technologies (AMPT2010). Paris (France), 24–27 Oct 2010, AIP Conference Proceedings, Melville, New York, pp 763–768

Vollertsen F, Blaurock L (2009) Einfluss der Umformgeschwindigkeit und der Messauflösung auf das Formänderungsverhalten in der Mikroblechumformung. In: Vollertsen F, Büttgenbach S, Kraft O, Michaeli W (eds) 4th kolloquium mikroproduktion. BIAS-Verlag, Bremen, pp 243–252

Wielage H, Schulze Niehoff H, Vollertsen F (2008) Forming behavior in laser shock deep drawing. In: International conference on high speed forming 2008, ICHSF 2008, Proceedings. University of Dortmund, Institut für Umformtechnik und Leichtbau, Dortmund, Germany, March 11–12 2008, pp 213–222

Wielage H, Vollertsen F (2011) Undercuts by laser shock forming. In: The 14th international ESAFORM conference on material forming. AIP conference proceedings 1353. American Institute of Physics, ISBN 978-0-7354-0911-8, pp 1309–1312

Wielage H, Vollertsen F (2011) Analysis of fracture behavior in plastic shaping by laser shock forming. In: Proceedings international conference on technology of plasticity (ICTP) 2011, 25–30 Sept 2011, Aachen, Deutschland, pp 1076–1080

Hintz G (1997) Untersuchung der Druckerzeugung und der Strahl-Stoff-Wechselwirkung an einem Excimerlaser-System für die Schockbehandlung von Metallen. Dissertation, Universität Erlangen-Nürnberg

Eisner K (1998) Prozeßtechnologische Grundlagen zur Schockverfestigung von metallischen Werkstoffen mit einem kommerziellen Excimerlaser. Dissertation, Universität Erlangen-Nürnberg

Li Q, Hong Y, Ye J, Wen M, Wang G (2010) Study of the velocity of a laser supported detonation wave, lasers in engineering, vol 19. Old City Publishing, Philadelphia, pp 153–161

Träger F (2012) Springer handbook of lasers and optics. Springer, Berlin, p 95

Fraden J (2010) Handbook of modern sensors: physics, designs, and applications, 4th edn. Springer, Berlin, p 86ff

Sulemann A (2001) Smart structures: applications and related technologies (CISM international centre for mechanical sciences). Springer, Berlin, p 5

Sanches JM, Laine AF, Suri JS (2012) Ultrasound imaging: advances and applications. Springer, Berlin, p 286f

Shull PJ (2002) Nondestructive evaluation: theory, techniques, and applications (Dekker mechanical engineering), 1st edn. CRC Press, Boca Raton, FL, p 91

Wüstenberg H, Rotter B, Erhard A, Möhrle W, Pitkänen J (1989) A parametric study of ultrasonic probes with PVDF-Transducers. In: Boogard J, van Dijk GM (eds) Proceedings 12th world conference on non-destructive testing. Elsevier, Amsterdam, NL, pp 691–698

Wielage H, Vollertsen F (2012) Difficulties and prevention methods in mechanical and non-mechanical micro drawing with high work piece velocities. In: Yuan SJ, Vollertsen F, Wang ZR, Dean TA (eds) Proceedings of the 3rd international conference on new forming technology (INCFT), Harbin, China, Aug 26–28, 2012, China, pp 24–29

Acknowledgments

This work has been funded by the Project VO530/65-1 “Fügen durch Hochgeschwindigkeitsumformen durch laserinduzierte Schockwellen”. The authors would like to thank the Deutsche Forschungsgemeinschaft for their financial support within the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Veenaas, S., Wielage, H. & Vollertsen, F. Joining by laser shock forming: realization and acting pressures. Prod. Eng. Res. Devel. 8, 283–290 (2014). https://doi.org/10.1007/s11740-013-0521-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0521-z