Abstract

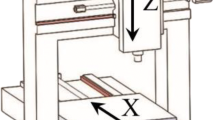

Machine tools in gantry design are commonly used to produce very large workpieces e.g. in the aerospace industry. The increasing accuracy requirements of the workpieces demand a very stiff machine design. But high stiffness leads to increased force flux and tension within the machine tool due to existing geometric errors or thermal influences. Especially geometric errors in the rails impede the synchronous movement of the two gantry drive systems and lead to position errors. To achieve high positioning accuracy despite the named geometric errors, high drive forces are necessary. These drive forces tension the gantry bridge. However, high forces lead to increased drive currents and, thus, reduce the machine dynamics and increase the energy consumption. In this paper, the interactions between geometrical errors and drive currents are investigated. Based on that, a multi-variable control to compensate for these tensions is introduced. That way the tension currents have been reduced by 86 %.

Similar content being viewed by others

References

Altintas Y, Verl A, Brecher C, Uriarte L, Pritschow G (2011) Machine tool feed drives. CIRP Ann Manuf Technol 60:779–796. doi:10.1016/j.cirp.2011.05.010

Weck M, Brecher C (2006) Werkzeugmachinen 5 Messtechnische Untersuchung und Beurteilung, dynamische Stabilität. Springer, Heidelberg

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann Manuf Technol 57:660–675. doi:10.1016/j.cirp.2008.09.008

Lee S, Yoo J, Yang M (2003) Effect of thermal deformation on machine tool slide guide motion. Tribol Int. doi:10.1016/S0301-679X(02)00128-7

Weck M, Brecher C (2006) Werkzeugmaschinen Konstruktion und Berechnung. Springer, Heidelberg

Nelles O (2013) Regelungstechnik-script. University of Siegen, Siegen

Tanquary M, Singer NC, Rappole Jr BW (2000) Method and apparatus for the control of gantry machines, US-patent US 6163116 A

Gomand J, Bearee R, Kestelyn X, Barre JP (2007) Physical dynamic modelling and systematic control structure design of a double linear drive moving gantry stage industrial robot. European conference power electronics and applications

Yu D, Li D, Hu Q (2012) Synchronous control for a dual linear motor of moving gantry machining centers based on improved sliding mode variable structure and decoupling control. Chinese Control and Decision Conference (CCDC)

Garciaherreros I, Kestelyn X, Gomand J, Barre JP (2010) Model-based control of a dual-drive H-type gantry stage on a decoupling base. IEEE International Symposium on Industrial Electronics (ISIE) 2:547–552. doi:10.1109/ICIT.2010.5472741

Garciaherreros I, Kestelyn X, Gomand J, Barre JP (2010) Decoupling basis control of dual-drive gantry stages for path-tracking applications. IEEE International symposium on industrial electronics (ISIE) 2:131–136. doi:10.1109/ISIE.2010.5637612

Berkemer J, Petzold M (2006) Effektive Nutzung des Leistungspotentials von Direktantrieben durch Impulskopplung, Beschleunigungsregelung, achsübergreifende Regelung und gekoppelte Simulation. VDI-Verlag, Düsseldorf

Teo C, Tan K, Huang S, Lim SY (2005) Dynamic modeling and adaptive control of a multi-axial gantry stage. IEEE Int Conf Syst Man Cybernet 4:3374–3379. doi:10.1109/ICSMC.2005.1571668

Teo CS, Tan KK, Lim SY, Huang S, Tay EB (2007) Dynamic modeling and adaptive control of a H-type gantry stage. Mechatronics 17(7):361–367. doi:10.1016/j.mechatronics.2007.04.004

Wu SY, Fu YY, Mi CT (2011) Modeling and control of twin parallel-axis linear servo mechanisms for high-speed machine tools. Int J Autom Smart Technol. doi:10.5875/ausmt.v1i1.72

Tan KK, Lim SY, Huang S, Dou HF, Giam TS (2004) Coordinated motion control of moving gantry stages for precision applications based on an observer-augmented composite controller. IEEE Trans Control Syst Technol 12(6):984–991. doi:10.1109/TCST.2004.833608

Zhao XM, Guo QD (2005) Synchronous control of gantry moving type boring-milling machining centers based-on disturbance observer. Proceedings of the eight international conference on electrical machines and systems 2:1573–1575. doi:10.1109/ICEMS.2005.202814

Gomand J, Kestelyn X, Bearee R, Barre JP (2010) Dual-drive gantry stage decoupling control based on a coupling model. Proceedings of the eight international conference on electrical machines and systems 2:131–136. doi:10.1109/ISIE.2010.5637612

Umezawa K, Kakinuma Y, Katsura S, Ohnishi K, Aoyama T, Yokoi K (2008) Interaction mode control for the machine tool table with three linear servo motors. J Adv Mech Des Syst Manuf 2(4):482–492. doi:10.1299/jamdsm.2.482

Zirn O (2008) Machine tool analysis—modelling, simulation and control of machine tool manipulators. Habilitation, ETH Zürich

Neugebauer R, Drossel W, Pagel K (2011) Regelungskonzept für Maschinen mit verkoppelten Achsen. Dresdner Werkzeugmaschinen-Fachseminar 14:61–71

Leyffer S (2005) The return of the active set method. Oberwolfach Report

Acknowledgments

The authors would like to thank the “Federal Ministry for Economic Affairs and Energy (BMWi)” for their financial support of the presented research project Aktiv-G.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Litwinski, K.M. & Eckl, M. Modeling and compensation of the interactions between geometrical errors and drive currents in directly driven gantry machine tools. Prod. Eng. Res. Devel. 9, 257–267 (2015). https://doi.org/10.1007/s11740-015-0600-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-015-0600-4