Abstract

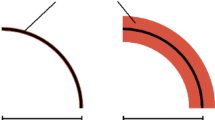

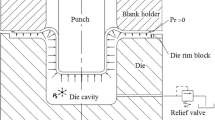

In this study, the impact of tool geometry variations on the punch force in micro deep drawing of rectangular parts was investigated. In contrast to deep drawing of rotationally symmetrical components in deep drawing of rectangular parts further tool geometry parameters, such as the corner radii of the die and punch influence the process and the process result. However, their impact on a micro deep drawing process is not known. Experimental micro deep drawing tests, as well as FEM simulations were carried out to determine the punch forces for a variation of the corner radius and the die radius. It could be demonstrated that an increasing corner radius size leads to an increasing punch force in deep drawing. Enlarging the corner radius from 147 to 250 µm resulted in a 36 % higher punch force. In contrast, an increase of the die radius size results in a decreasing punch force. Here, enlarging the die radius from 76 to 143 µm led to a decrease of the punch force of 26 %.

Similar content being viewed by others

References

Hesselbach J, Raatz A, Wrege J, Herrmann H, Weule H, Buchholz C, Tritschler H, Knoll M, Elsner J, Klocke F, Weck M, von Bodenhausen J, von Klitzing A (2003) mikroPro—Untersuchungen zum internationalen Stand der Mikroproduktionstechnik. wt Werkstattstechnik online 93(3):119–128

Mescheder U (2004) Mikrosystemtechnik—Konzepte und Anwendungen, 2nd edn. Teubner, Stuttgart

Hirt G, Bambach M, Justinger H, Zhao K (2009) Bedeutung von Größeneffekten für die Mikro-Blechumformung. In: Vollertsen F (ed) Größeneinflüsse in Fertigungsprozessen. BIAS, Bremen, pp 117–134

Geiger M, Kleiner M, Eckstein R, Tiesler N, Engel U (2001) Microforming. Ann CIRP 50:445–462

Hu Z (2008) Analyse des tribologischen Größeneffekts beim Blechumformen. In: Strahltechnik 33. BIAS, Bremen

Raulea LV, Goijaets AM, Govaert LE, Baaijens FPT (2009) Size effects in the processing of thin metal sheets. In: Proceedings of the SheMet’99, pp 521–528

Vollertsen F, Biermann D, Hansen HN, Jawahir IS, Kuzman K (2009) Size effects in manufacturing of metallic components. CIRP Ann Manuf Technol 58:566–587

Hu Z, Walter R, Vollertsen F (2009) Forming tools for micro deep drawing—influence of geometrical tolerance of forming tools on the punch force in micro deep drawing. wt Werkstattstechnik online H 11(12):814–819

Behrens G, Vollertsen F (2013) Influence of tool geometry variation on the punch force in micro deep drawing. In: Alves de Sousa R, Valente R (eds) Proceedings of the ESAFORM 2013 ‘Key Engineering Materials’, vol 554–557. Trans Tech Publications, Schweiz, pp 1306–1311

Behrens G, Trier FO, Vollertsen F (2014) Influence of tool geometry variations on the limiting drawing ratio in micro deep drawing. Int J Mater Form (in print)

Brinksmeier E, Vollertsen F, Riemer O, Flosky H, Behrens G, Böhmermann F (2013) Mikrofräsbearbeitung zur Herstellung leistungsfähiger Mikroumformwerkzeuge. In: Tutsch R (ed) Proceedings of the 6th colloquium of micro production, Braunschweig, ISBN:978-3-8440-2243-8, (2013), pp A23-1–A23-8

Hu Z, Vollertsen F (2011) Investigation on the optimisation of the blank shape for micro deep drawing of rectangular parts. In: Hirt G, Tekkaya AE (eds) Proceedings of the ICTP 2011, Stahleisen GmbH, Düsseldorf, pp 974–978

Doege E, Behrens B-A (2007) Handbuch Umformtechnik. Springer, Berlin, p 269

Acknowledgments

The authors gratefully acknowledge the financial support by the German Research Foundation (DFG) for the subproject B7 of the Collaborative Research Centre 747. Special thanks go to the involved employees of the Laboratory for Precision Machining LFM for preparation of the tool geometries and the employees of the Bremen Institute for Metrology, Automation and Quality Science BIMAQ for tactile measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, G., Ruhe, M., Tetzel, H. et al. Effect of tool geometry variations on the punch force in micro deep drawing of rectangular components. Prod. Eng. Res. Devel. 9, 195–201 (2015). https://doi.org/10.1007/s11740-015-0604-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-015-0604-0