Abstract

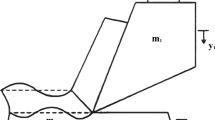

In order to achieve the energy and efficiency goals in modern automotive press shops, press systems with increasingly high stroke rates are being implemented (Meinhardt in proceedings of ACI forming in car body engineering. Bad Nauheim, Germany 2012). As a side effect, the structural dynamic loads on the press and especially on the forming tool increase. Hence, to design reliable and withstanding forming tools, a detailed knowledge of the vibrations and resulting critical loads is essential. In this paper, the main focus is put on the vibration of the blankholder—the heaviest moving component in the forming tool. To predict those vibrations, a coupled multibody-finite element simulation (MBS-FEM) is conducted, which combines rigid and elastic modeling approaches. Also, an experimental validation of the blankholder vibration under operational load is carried out. To compare the numerical and experimental results—both in time and frequency domain—an 1/3-octave analysis of a blankholder’s vibrational speed is performed. The test measurements agree well with the MBS-FEM simulation.

Similar content being viewed by others

References

Meinhardt J (2012) First experience at BMW with the use of servo press technology. In: Proceedings of ACI forming in car body engineering, Bad Nauheim, Germany, 26–27 September 2012

Osakada K, Mori K, Altan T, Groche P (2011) Mechanical servo press technology for metal forming. CIRP Ann Manuf Technol 60:651–672

Altan T, Groseclose A (2009) Servo-drive pressesrecent developments. 5th international conference and exhibition on design and production of MACHINES and DIES/MOLDS. Aydin, Turkey, June 2009

Heston T (2008) The science behind the servo press. Fabricator 38(1):34–39

Altan T, Groseclose A, Billur E, Subramonian S, Mao T (2013) Advances and challenges in sheet metal forming technology. 7th international conference on design and production of machines and dies/molds. Antalya, Turkey, June 2013, pp 1–6

Osborn A, Paul S (2008) Servo-Press Technology—drive design and performance. Met Form 42(8):18–23

Lin B-T, Kuo C-C (2008) Application of an integrated CAD/CAE/CAM system for stamping dies for automobiles. Int J Adv Manuf Technol 35(9–10):1000–1013

Firat M (2007) Computer aided analysis and design of sheet metal forming processes: part III: stamping die-face design. Mater Des 28(4):1311–1320

Schneider D (2008) Simulationsgestützte Untersuchung der Werkzeugbelastung beim Tiefziehen höchstfester Stähle. PhD thesis. München: Technische Universität München, Fakultät für Maschinenwesen

Watanabe A, Watari H, Yamazaki T (2012) Basic study on dynamic characteristics for servo-press machine. In: Proceedings of SICE annual conference (SICE). Akita, Aug. 2012, pp 1477–1480

Wifi A, Mosallam A (2007) Some aspects of blankholder force schemes in deep drawing process. J Achiev Mater Manuf Eng 24(1):315–323

Wagener H-W (1997) New developments in sheet metal forming: sheet materials, tools and machinery. J Mater Process Technol 72:342–357

Nitschke L (1993) Nichtlineare dynamische Berechnungsmodelle mechanischer Pressen unter Berücksichtigung exzentrischer Belastungen. PhD thesis. Technische Universität Dresden, Fakultät für Maschinenwesen, Dresden

Pahl K (1994) Elastische Wechselwirkungen im Ziehapparat einfachwirkender Pressen. PhD thesis. Gesamthochschule Kassel, Düsseldorf

Großmann K, Wiemer H, Hardtmann A, Penter L (2008) The advanced forming process model including the elastic effects of the forming press and tool. Archiv Civil Mech Eng 8(3):41–45

Großmann K, Penter L, Hardtmann A, Weber J, Lohse H (2012) FEA of deep drawing with dynamic interactions between die cushion and process enables realistic blank holder force predictions. Archiv Civil Mech Eng 12(3):273–278

Del Pozo D, López de Lacalle L, López J, Hernández A (2008) Prediction of press/die deformation for an accurate manufacturing of drawing dies. Int J Adv Manuf Technol 37(7–8):649–656

Lingbeek R, Meinders T, Ohnimus S (2008) Compensation of deep drawing tools for springback and tool-deformation. IDDRG, International Deepdrawing Research Group International Conference. Olofstrom, Sweden, June 2008, pp 475–486

Krušic V, Arentoft M, Mašera S, Pristovšek A, Rodic T (2011) A combined approach to determine workpiece-tool-press deflections and tool loads in multistage cold-forging. J Mater Process Technol 211(1):35–42

Hojny M (2010) Application of an integrated CAD/CAM /CAE/IBC system in the stamping process of a bathtub. Arch Metall Mater 55(3):713–723

Schenke C-C, Wiemer H, Großmann K (2012) Analysis of servo-mechanic drive concepts for forming presses. Prod Eng Res Dev 6(4):467–474

Brecher C, Klein W, Tannert M (2010) Optimization of multi-stage closed-die forging processes by coupled simulation of the machine and the forging processes. Prod Eng Res Dev 4(2):279–286

Zaeh M, Siedl D (2007) A new method for simulation of machining performance by integrating finite element and multi-body simulation for machine tools. CIRP Ann Manuf Technol 56(1):383–386

Behrens B-A, Krimm R, Kammler M, Wager C, Schrödter J (2012) Fatigue analysis of a mechanical press by means of the hybrid multi-body simulation. Prod Eng Res Dev 6(4–5):421–430

Kashid S, Kumar S (2014) Prediction of life of compound die using artificial neural network (ANN). Key Eng Mater 622–623:664–671

Hamedon Z, Mori K, Abe Y (2014) In-situ measurement of three-dimensional deformation behaviour of sheet and tools during stamping using borescope. Mater Des 214:945–995

Lo S-W, Jeng G-M (1999) Monitoring the displacement of a blank in a deep drawing process by using a new embedded-type sensor. Int J Adv Manuf Technol 15:815–821

Subramonian S, Altan T, Campbell C, Ciocirlan B (2013) Determination of forces in high speed blanking using FEM and experiments. J Mater Process Technol 213(12):2184–2190

Salfeld V, Matthias T, Krimm R, Behrens B-A (2012) Analysis of machine influence on process stability in sheet bulk metal forming. In: Proceedings of the 45th CIRP conference on manufacturing systems, vol 3, pp 32–36

Teichrib S, Salfeld V, Krimm R, Behrens B-A (2013) Untersuchung der Stößelführungsbelastung an Pressen. Umformtechnik, UTF Science, Meisenbach Verlag Bamberg, vol IV/2013

Koss LL, Moffatt JA (1982) Vibration and acoustic data for a punch press. J Sound Vib 80(4):543–554

Luo Y, Du R (2012) An investigation on the impact noise of a six-bar linkage mechanical press. Proc Eng 29:1486–1491

Yamazaki T, Watanabe A (2014) Simplified modeling and dynamic analysis for servo press machine. Int J Eng Sci Innov Technol 3(5):344–348

Müller P, Kranz B, Kriechenbauer S, Schlegel H (2015) Experimental and numerical modal analysis of a servo-screw press with coupled drives as a basis for increasing flexibility and dynamics. Prod Eng Res Dev 9(2):203–214

Groche P, Christiany M, Brüninghaus G (2013) Servopressen sind wegen ihrer Emissionswerte auch salonfähig. MaschinenMarkt 32(33):26–28

Jeswiet J, Geiger M, Engel U, Kleiner M, Schikorra M, Duflou J, Neugebauer R, Bariani P, Bruschi S (2008) Metal forming progress since 2000. CIRP J Manuf Sci Technol 1(1):2–17

Lee MG, Kim C, Pavlina EJ, Barlat F (2011) Advances in sheet forming—materials modeling, numerical simulation, and press technologies. J Manuf Sci Eng 133(6):061001

GmbH Schuler (1998) Metal forming handbook. Springer, Berlin

Negrut D, Dyer A (2004) ADAMS/Solver Primer, Ann Arbor, August 2004

Ortiz J (2014) Nonlinear flexibility in Adams. MSC User Meeting, Munich, 14–15 May 2014

Bayrasy P, Burger M, Dehning C, Kalmykov I, Speckert M (2012) Applications for MBS-FEM-coupling with MpCCI using automotive simulation as example. SIMULIA community conference 2012. Frankfurt

Indermuehle KC (2011) Advanced mutli-body dynamics: fully coupled kinematics with nonlinear FEA. 52nd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference. Denver, Colorado, 19th 4–7 April 2011

RecurDyn Multibody Software. FunctionBay, Inc., (2015)

Schwertassek R, Wallrapp O, Shabana A (1999) Flexible multibody simulation and choice of shape functions. Nonlinear Dyn 20(4):361–380

Hurty WC (1965) Dynamic analysis of structural systems using component modes. AIAA J 3(4):678–685

Craig R, Bampton M (1968) Coupling of substructures for dynamic analysis. AIAA J 6(7):1313–1319

Dietz S, Wallrapp O, Wiedemann S (2003) Nodal versus modal representation in flexible multibody system dynamics. Multibody dynamics 2003, international conference on advanced in computational multibody dynamics. IDMEC, Lisbon

Hoffmann H, Neugebauer R, Spur G (2012) Handbuch Umformen. Hanser Verlag, München

Simo J, Vu-Quoc L (1988) On the dynamics in space of rods undergoing large motions—a geometrically exact approach. Comput Methods Appl Mech Eng 66(2):125–161

Crisfield M, Moita G (1996) A unified co-rotational framework for solids, shells and beams. Int J Solids Struct 33(20–22):2969–2992

RecurDyn Solver Theoretical Manual (2011) 7th ed. FunctionBay, Inc

Kelichhaus T (2013) Nonlinear flexible—body contact analysis in a coupled MBD and FEA simulation. NAFEMS European Conference Coupled MBS-FE Applications, Frankfurt

Dresig H, Holzweißig F (2010) Dynamics of machinery—theory and applications. Springer, Berlin

Hertz H (1881) Über die Berührung fester elastischer Körper. Journal für die reine und angewandte Mathematik 92:156–171

Defeaturing. http://www.esocaet.com/wikiplus/index.php/Defeaturing. CADFEM CAE Wiki. 2012. Accessed 10 April 2015

Meckl D, Lubeseder C, Swidergal K (2014) Simulation of press dies for large presses using the flexible multibody dynamics in RecurDyn. 4th RecurDyn TechnologyDays 2014, Munich, Germany, 5–6 Nov 2014

Thumann P, Swidergal K, Wagner M (2015) Calculation and validation of material tests with specimens made out of filled elastomers. In: Proceedings of the 10th European LS-DYNA conference, Würzburg

Babuška I, Suri M (1992) Locking effects in the finite element approximation of elasticity problems. Numer Math 62(1):439–463

Randall RB (1987) Frequency analysis, 3rd edn. Brüel & Kjaer, Copenhagen

Swidergal K, Lubeseder C, von Wurmb I, Meinhardt J, Wagner M, Marburg S (2014) Vibration analysis of an automotive forming tool using coupled MBS-FEM simulation and experimental validation. In: ISMA proceedings of the international conference on noise and vibration engineering. Leuven, Belgium, Sept. 2014, pp 2931–2942

imc Meßsysteme GmbH. imc FAMOS Function Reference (2013)

DIN 45661:2012-08. Schwingungsmeßeinrichtungen - Begriffe (2012)

Molzberger H, Leitgeb M (2011) Dynamische Messungen - Bericht Nr. B482121b. Tech. rep. imb- Dynamik GmbH

Lening V (2014) Betriebsfestigkeitsberechnung einer Werkzeugkomponente mittels ANSYS und FEMFAT. M.Sc. thesis. Ostbayerische Technische Hochschule Regensburg

Hederer S (2015) Entwicklung und Validierung eines rheologischen Materialmodells für gefüllte Elastomere. B.Sc. thesis. Ostbayerische Technische Hochschule Regensburg

Swidergal K, Lubeseder C, von Wurmb I, Lipp A, Meinhardt J, Wagner M, Marburg S (2015) Structural analysis of an automotive forming tool for large presses using LS-DYNA. In: Proceedings of the 10th European LS-DYNA conference, Würzburg, Germany

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Swidergal, K., Lubeseder, C., von Wurmb, I. et al. Experimental and numerical investigation of blankholder’s vibration in a forming tool: a coupled MBS-FEM approach. Prod. Eng. Res. Devel. 9, 623–634 (2015). https://doi.org/10.1007/s11740-015-0640-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-015-0640-9